How Slew Drives Work in Welding Positioners: Precision Motion Explained

Introduction

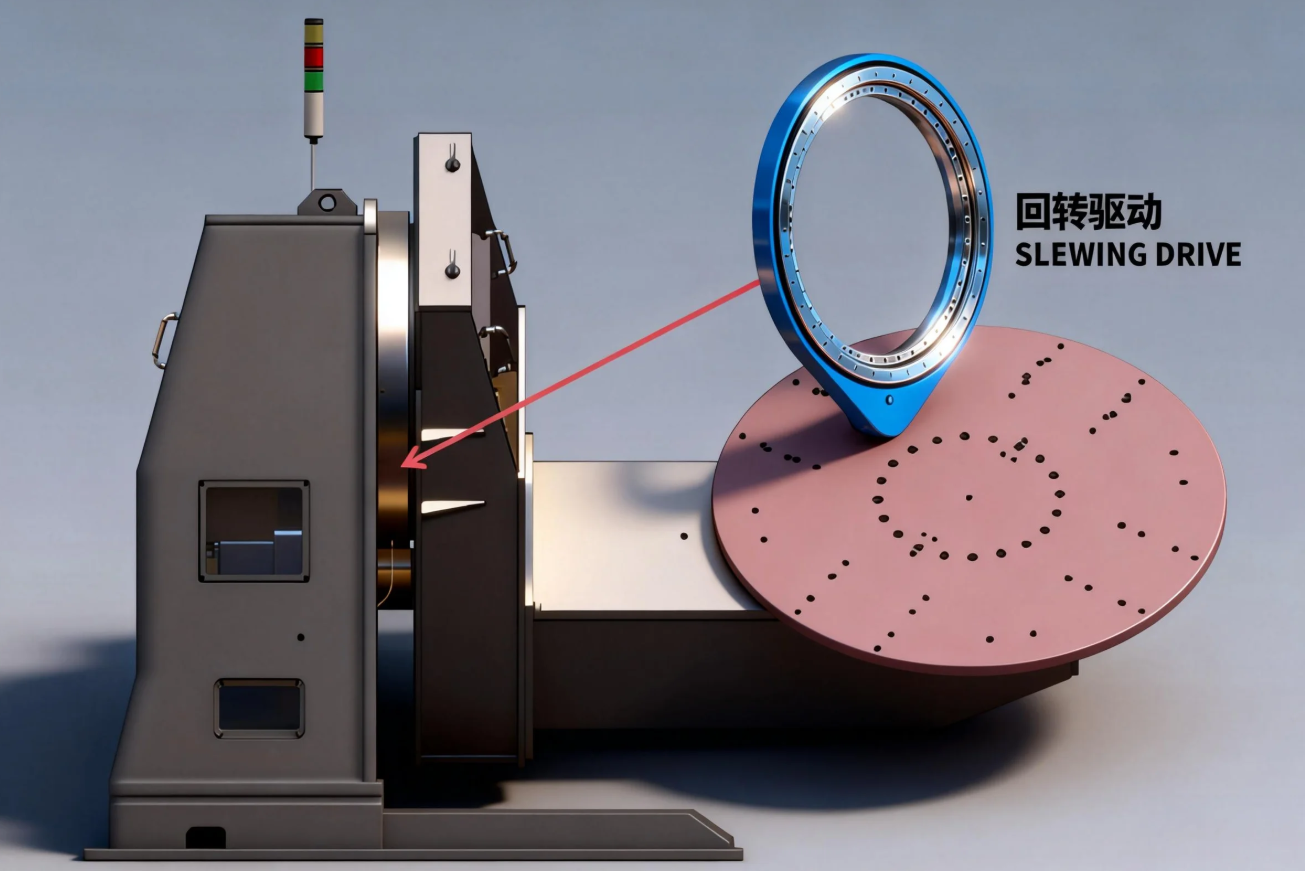

In modern welding technology, achieving high-quality, efficient, and repeatable welds is paramount. Welding positioners are critical to this process, enabling precise orientation of the workpiece to position the weld seam ideally for the operator or automated system. At the heart of many advanced positioners lies a key component: the slew drive. This highly integrated rotational mechanism is fundamental to delivering the precise, stable, and powerful motion required for superior welding results across diverse industrial applications.

What is a Slew Drive?

A slew drive is a compact, highly integrated rotary drive system that combines three essential functions into a single, robust unit: rotation, speed reduction, and torque transmission. Its core design integrates a slewing bearing—a large-diameter bearing capable of handling heavy axial, radial, and moment loads—with a built-in reduction gear mechanism, typically worm gear or planetary gear.

This ingenious design uses one race of the slewing bearing as the driven element and the attachment point for the workload (like a positioner's table or tilt arm), while the other race is fixed to the drive source and housing. This creates a complete, modular drive package that is structurally efficient, simplifying both the overall machine design and on-site installation and maintenance.

How Do Slew Drives Work in a Welding Positioner?

In a welding positioner, slew drives are primarily employed in two core motions: the table rotation and the tilt/positioning mechanism.

Table Rotation: Here, the slew drive provides smooth, continuous 360-degree rotary motion to the worktable. It allows for precise, stepless speed control, enabling operators to maintain an optimal, consistent welding speed. This is crucial for achieving uniform weld bead appearance and quality, especially in automated or precision applications.

Tilt & Positioning: Slew drives enable the precise tilting and orientation of the workpiece. In common designs like L-type double-motion positioners, a slew drive allows the main arm to tilt forward and backward around a horizontal axis, while another (or the same) unit can facilitate rotation around a vertical axis. This dual-axis control, powered by servo or other motors through the slew drive, allows welders to position complex, multi-faceted workpieces so that every weld seam can be performed in the preferred flat or horizontal position, ensuring optimal weld pool control and accessibility.

The Characteristics of Slew Drives in Welding Positioners

The integration of slew drives provides welding positioners with distinct performance advantages:

High Precision & Repeatability: Slew drives enable accurate angular positioning and high repeatability, which is essential for consistent weld seam placement and automated welding cycles. This minimizes rework and ensures uniform quality.

Superior Load Capacity & Rigidity: The inherent design of the slewing bearing provides exceptional load-bearing capacity, rigidity, and resistance to deformation under heavy or off-center loads. This allows a single positioner to handle a wide range of workpiece sizes and weights reliably.

Self-Locking Safety (Worm Gear Type): Worm gear slew drives offer a natural reverse motion lock—the worm can drive the gear, but the gear cannot back-drive the worm. This crucial safety feature holds the workpiece securely in any tilted position without the need for external brakes, preventing unintended movement.

Compact & Modular Design: Their high level of integration simplifies the positioner's structure, saves space, and reduces the need for users to source and assemble multiple components like separate bearings, gears, and housings. This streamlines manufacturing and maintenance.

High Reduction Ratios & Torque: The compact design can achieve high reduction ratios and output torque in a small footprint, providing the necessary power for smooth, controlled movement of heavy loads at operational speeds.

What Can Lyradrive Do for Your Welding Positioner Slew Drives?

As a leading domestic manufacturer specializing in high-performance slew drive solutions, Lyradrive is your ideal partner for enhancing your welding positioner's capabilities. We understand the critical demands of precision welding and offer more than just components—we provide engineered motion solutions.

Lyradrive can provide your welding positioner with more professional, reliable, and high-performance slew drive systems, featuring:

Custom-Engineered Designs: We tailor our slew drives to match your specific load, speed, precision, and mounting requirements, ensuring optimal integration and performance.

Robust Construction for Demanding Environments: Our drives are built to withstand the harsh conditions of welding shops, including dust, spatter, and continuous operation.

Enhanced Precision Gearing: We focus on manufacturing tolerances and gear quality to ensure smooth operation, minimal backlash, and exceptional positional accuracy for superior weld quality.

Comprehensive Technical Support: From initial design consultation to after-sales service, our team provides expert support to ensure your welding systems perform at their peak.

Choose Lyradrive to power your precision. Let our slew drive technology provide the solid foundation of motion control that your high-quality welding positioners demand.