How Does Slewing Drive Work?

Have you ever wondered how massive construction cranes rotate smoothly under enormous loads or how solar panels track the sun's movement with such precision? The engineering behind these impressive motions often relies on a compact yet powerful component known as the slewing drive. This integrated system is the unsung hero behind precise, high-torque rotation in countless industrial applications.

What is Slewing Drive?

A slewing drive is a highly engineered, compact gearbox designed to provide controlled rotational movement while supporting heavy loads. It combines a worm gear mechanism with a large-diameter slewing bearing into a single, sealed unit. Its primary function is to convert the high-speed, low-torque input from a motor into a powerful, low-speed, high-torque output, enabling precise and stable rotation of large structures.

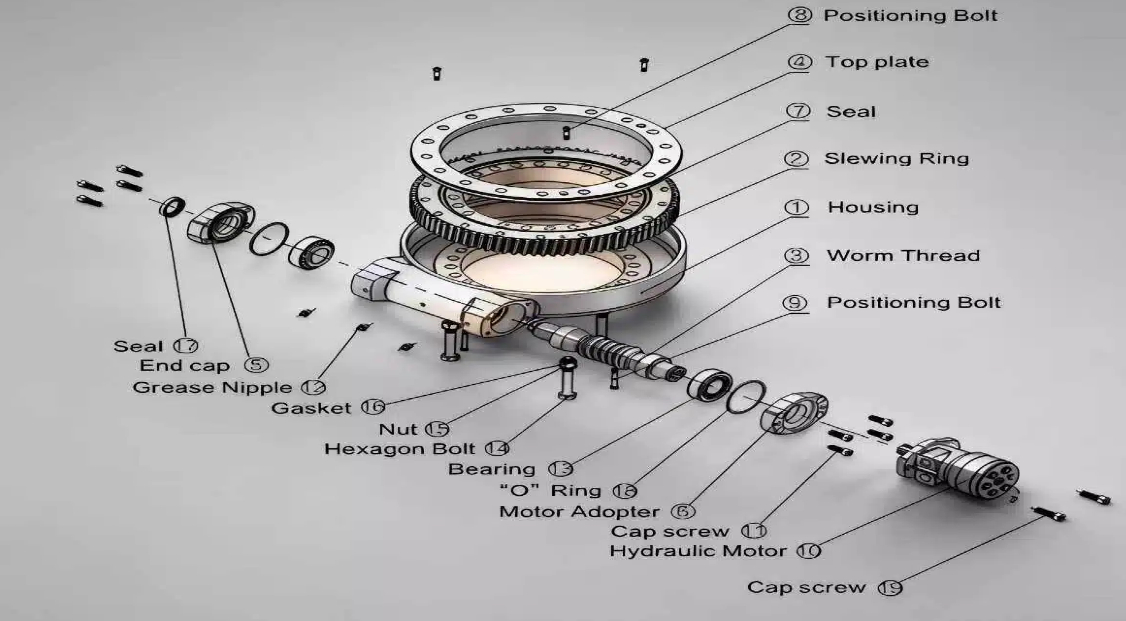

Components of a Slewing Drive

The efficiency of a slewing drive stems from the seamless integration of its key components. The following diagram illustrates how these prts work together:

Worm Gear: The central component, consisting of a worm (a helical gear) and a worm wheel (a gear that meshes with the worm).

Housing: Encases the worm and worm wheel, providing structural support and protection.

Bearings: Support the radial and axial loads and facilitate smooth rotation.

Seals: Prevent contaminants from entering and ensure lubrication remains inside.

Lubrication System: Maintains the efficiency and longevity of the worm gear mechanism.

Motors and Brakes: Often integrated to provide rotational power and control.

How Does Slewing Drive Work?

The operation of a slewing drive is a masterclass in mechanical advantage and control. Here’s a step-by-step breakdown of its working principle:

Power Input: An external power source—typically an electric or hydraulic motor—initiates rotation of the worm shaft.

Gear Reduction and Torque Multiplication: As the worm rotates, its helical threads engage the teeth of the worm wheel. This interaction provides a very high gear reduction ratio. For example, a single rotation of the worm may advance the wheel by only one tooth. This dramatically reduces the output speed while simultaneously multiplying the output torque.

Load Rotation: The worm wheel is directly connected to, or is part of, the slewing bearing's raceway. Therefore, the amplified torque is transferred directly to the bearing's outer structure, causing the entire attached platform or boom to rotate smoothly.

Self-Locking and Precision: A key feature of the worm gear design is its inherent self-locking capability. Due to the high friction angle in the gear mesh, force cannot be easily transmitted backwards from the wheel to the worm. This means the drive can hold its position securely against the load without needing a constantly engaged brake, which is critical for safety in applications like cranes. This also allows for exceptionally precise and stable positioning.

The Application Fields of Slewing Drives

The unique combination of high torque, compactness, and controlled motion makes slewing drives indispensable across many industries:

Renewable Energy: They are critical for solar trackers, enabling panels to follow the sun, and in wind turbines for yaw (nacelle) and pitch (blade) control.

Construction & Heavy Machinery: They provide the rotational movement for crane booms, excavator upper structures, and aerial work platforms.

Industrial Automation: Used in welding positioners, indexing tables, and robotic turntables for precise part manipulation.

Defense & Aerospace: Found in radar antenna and satellite dish positioning systems that require accurate tracking.

Material Handling: Essential for stacker-reclaimers and other large rotating machinery in ports and mills.

What Are the Advantages of Slewing Drives?

Choosing a slewing drive offers several compelling benefits over alternative drive systems:

High Torque in a Compact Package: The worm gear principle delivers immense torque multiplication from a relatively small input, all within an integrated unit that saves design space.

Exceptional Load Handling: The built-in slewing bearing is designed to manage substantial combined loads (axial, radial, and moment) directly at the rotation point.

Inherent Safety and Stability: The self-locking feature provides failsafe holding, preventing unintended movement and ensuring stability even when power is cut.

Simplified Design and Installation: By combining gears, bearings, and often seals and mounting provisions into one pre-assembled unit, it simplifies machine design, reduces assembly time, and minimizes points of failure.

Leading Slewing Drive Manufacturer

We understand that a superior slewing drive starts from the inside out. At LyraDrive, we integrate our own, rigorously manufactured slew bearings as the core load-bearing component within the drive assembly. This vertical integration allows us to ensure unmatched quality control, from the grade of steel and the precision of the gear teeth to the integrity of the final seal. We don't just assemble parts; we engineer cohesive systems where every component is optimized to work in perfect harmony.

What does this mean for you? It means you get a solution that is precisely tailored to your load, speed, and environmental requirements. You benefit from robust construction that guarantees longevity, expert technical support from initial concept through to installation, and the peace of mind that comes from a drive system built with the same commitment to excellence that defines our core bearing products. For a slewing drive that delivers reliable power and precision, trust the rotational experts at LyraDrive.