Custom Slew Drives: A Complete Guide to Engineered Rotary Motion Solutions

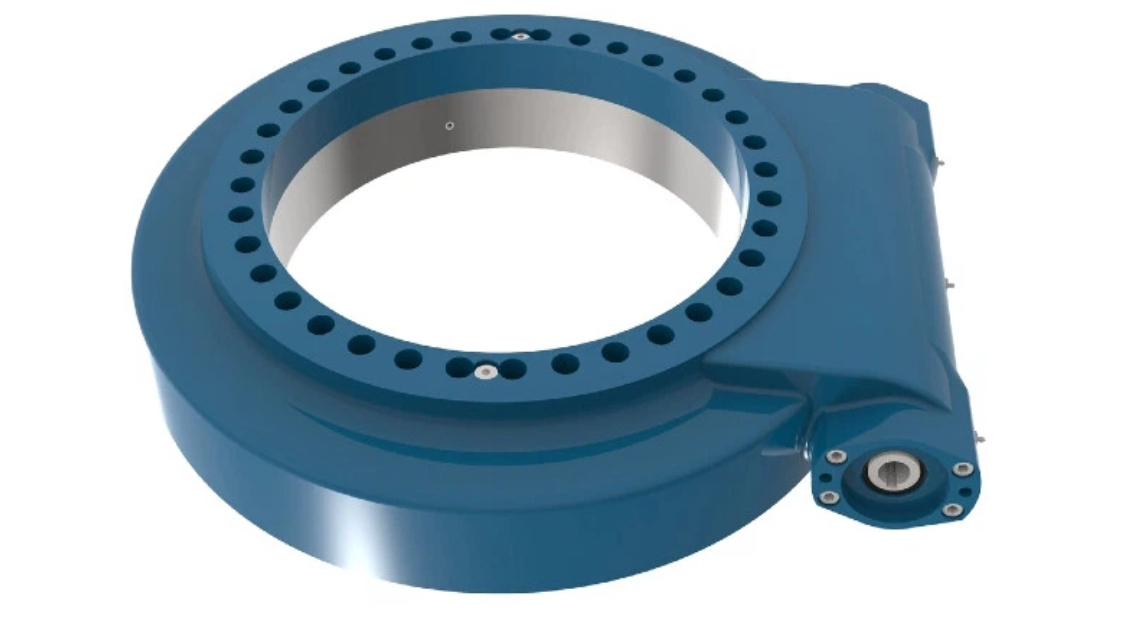

A custom slew drives a compact, highly integrated mechanical system that delivers precise, high-torque rotational movement. It is an all i-in-one unit combining a slewing bearing, worm gear mechanism, sealing system, and often integrated motor and brakes—all engineered as a single solution.

Standard off-the-shelf drives work well for generic requirements. But they are designed for averages, not for your specific application. They impose their bolt patterns, load ratings, and dimensional envelopes on your machine. You adapt your design to fit the component.

A custom slew drive reverses this relationship. It is specifically engineered to meet your unique dimensional, load, and performance requirements—delivering optimized performance where standard units fall short. At its core, it is the definitive solution for applications demanding robust, reliable, and controlled rotation in a compact envelope.

This guide explains how custom slew drives eliminate compromise, and how LyraDrive partners with engineers to engineer them right.

What is Slew Drive?

A sew drive is a gearbox designed to handle simultaneous axial, radial, and moment loads while providing rotational positioning. Unlike traditional speed reducers that manage only torque, a slew drive integrates a large-diameter bearing directly into the gear train.

Think of it as a "rotary motion platform." It accepts high-speed, low-torque input from a hydraulic motor, electric motor, or manual crank and converts it into low-speed, high-torque output that rotates a connected structure. Cranes, solar trackers, wind turbines, and aerial lifts all rely on this principle.

The defining characteristic of a slew drive is its slewing bearing—a specialized bearing that rotates while supporting substantial off-center weight. This integration of bearing and drive mechanism is what makes slew drives uniquely suited for heavy-duty positioning tasks.

Components of a Slew Drive

To understand customization, you must first understand the parts that can be tailored. A typical slew drive consists of five core systems:

| Component | Function | Customization Potential |

|---|---|---|

| Slewing Ring (Bearing) | Supports radial, axial, and moment loads; enables rotation | Raceway geometry, internal clearance, roller/ball type, integrated raceway hardening |

| Worm Shaft & Gear | Provides speed reduction and torque multiplication; enables self-locking | Gear ratio, tooth profile, thread count, surface hardening depth |

| Housing | Encloses components; mounts drive to machinery | Material, ingress protection rating, mounting interface geometry, integrated fluid channels |

| Sealing System | Retains lubrication; excludes contaminants | Material compatibility, multi-lip designs, labyrinth seals, wipers |

| Lubrication | Reduces friction; dissipates heat; protects against wear | Synthetic vs. mineral, food-grade, extended-life additives, automated delivery interface |

Each component presents an opportunity for optimization. At LyraDrive, we treat no element as "standard" until we have validated it against your specific operating conditions.

How Does a Slew Drive Work?

A slew drive operates on the worm and worm gear principle. The input shaft, fitted with a threaded worm, engages teeth on the outer diameter of the slewing ring. As the worm rotates, it advances the ring incrementally.

This configuration offers two significant advantages:

High reduction in a single stage – A single-turn input can advance the output by only one tooth, creating substantial torque multiplication.

Self-locking capability – Depending on the lead angle, the worm can prevent the output from back-driving the input. This is critical for safety in applications like man-lifts and suspended platforms.

The precision of this engagement—the mesh between worm and gear—directly determines the drive's backlash. Backlash is the "play" between components, measured in arc-minutes. Standard drives may offer 15–20 arc-minutes. Custom engineered drives from LyraDrive regularly achieve precision below 1 arc-minute.

The Strategic Advantage: Why Engineer a Custom Slew Drive?

When engineers first consider customizing a slew drive, the natural question is: Is it worth the additional engineering investment?

The answer lies in viewing the slew drive not as a commodity, but as a performance multiplier. A standard drive may meet your load spec today, but a custom drive can improve your entire machine's efficiency, lifespan, and market competitiveness.

Architectural Freedom

Standard drives impose their bolt patterns, shaft orientations, and envelope dimensions on your design. With custom engineering, you decide where the drive mounts, how it interfaces with adjacent systems, and where the input motor locates. This freedom often eliminates complex linkage systems or compromises in frame design.

Weight and Material Optimization

In mobile applications—cranes, excavators, marine equipment—every kilogram matters. A custom slew drive allows optimized housing wall thickness, bearing race geometry, and material selection based on actual, not assumed, loads. LyraDrive has helped customers reduce drive weight by over 30% while maintaining or exceeding original performance specifications.

Environmental Adaptation

Consider a solar tracker in the Atacama Desert versus an offshore radar platform. One requires resistance to diurnal thermal cycling and airborne abrasives; the other demands full immersion protection and salt-fog corrosion resistance. Standard seals and coatings cannot satisfy both. Customization selects the correct seal compounds, surface treatments, and internal clearances for your environment.

System Integration

Modern machines are networks of sensors and actuators. A custom slew drive can incorporate encoder mounting pads, integrated limit switch cam tracks, hydraulic porting through the housing, or even embedded temperature sensors. This transforms the drive from a passive component into an active node in your control system.

Total Cost of Ownership

The initial unit cost of a standard drive may be lower. However, when you factor in:

Structural modifications required to fit a standard drive

Premature failures from inadequate seals or lubrication

Energy losses from mismatched gear geometry

Downtime and replacement logistics

—the custom solution frequently demonstrates superior lifecycle value. At LyraDrive, we work with customers to model this total cost equation before a single drawing is created.

Key Engineering Considerations for Custom Slew Drives

Designing a custom slew drive is an exercise in balance. Optimizing one parameter often affects another. Successful engineering requires understanding these interdependencies early.

Load Analysis: Beyond Static Capacity

Most standard drives are selected based on static load curves. For custom designs, we must consider dynamic loading: shock loads, duty cycle, oscillation frequency, and moment arm variation. LyraDrive engineers use FEA (Finite Element Analysis) to model stress distribution across the slewing ring under combined loads. This prevents both under-engineering (premature failure) and over-engineering (excess weight and cost).

Gear Geometry and Backlash

The worm and gear mesh is the heart of the drive. Customization allows us to select:

Tooth profile – Involute, cycloidal, or modified profiles for specific load/speed regimes

Backlash class – From standard commercial (10-20 arc-min) to precision (<1 arc-min)

Preload – In certain designs, the worm can be spring-loaded against the gear to eliminate backlash entirely

Material Science

Housings may be ductile iron, cast steel, aluminum, or corrosion-resistant alloys. Gears require case-hardened alloys with sufficient case depth to withstand repeated contact stresses. At LyraDrive, we maintain strict certification of raw materials and heat treat processes, ensuring repeatable metallurgical properties.

Sealing and Protection

Ingress protection is not binary. A drive rated IP65 may fail quickly in a high-pressure washdown environment if the seal material is incompatible with the cleaning chemistry. Custom seals consider:

Shaft speed and runout

Temperature extremes

Chemical exposure

Abrasive particulate

Sterilization cycles (for medical or food applications)

Thermal Management

Friction generates heat. In continuously operating drives, or those in high-ambient environments, thermal expansion alters gear mesh and degrades lubricant. Custom solutions may incorporate cooling fins, fluid circulation pathways, or high-temperature elastomers.

| Engineering Parameter | Standard Approach | Custom LyraDrive Approach |

|---|---|---|

| Load Rating | Based on generic curves | Application-specific FEA |

| Backlash | Fixed class | Specified and verified |

| Material | Single option | Selected for environment |

| Seal | Catalog selection | Designed for duty cycle |

| Testing | Sample batch | Unit-level validation |

The LyraDrive Difference: Our Custom Design & Manufacturing Workflow

Engineers do not merely purchase components; they purchase confidence. The LyraDrive custom workflow is structured to deliver that confidence through transparency, iteration, and validation.

Phase 1: Discovery and Specification

Every project begins with conversation. We request not only your dimensional requirements, but also:

Machine duty cycle and expected service life

Power source (electric, hydraulic, manual)

Control philosophy (open loop, closed loop, positioning accuracy)

Environmental severity

Integration constraints (cabling, adjacent components, maintenance access)

This phase often reveals requirements not originally identified.

Phase 2: Conceptual Engineering

LyraDrive design engineers develop multiple architectural approaches. A solar tracker may be optimized with an offset worm; a crane application may benefit from dual-worm anti-backlash. We present options with estimated performance, weight, and cost, allowing you to make informed trade-offs.

Phase 3: Detailed Design and Simulation

Selected concepts progress to full 3D modeling. We simulate:

Gear contact stress and fatigue life

Housing deflection under peak load

Thermal rise under continuous operation

Lubricant distribution and retention

Simulation reports are shared, not withheld. We believe an informed customer is the best partner.

Phase 4: Prototyping and Validation

Before production tooling commits, LyraDrive manufactures prototype units. These are tested on our in-house dynamometers, capable of applying combined loads while measuring backlash, efficiency, and temperature. Where possible, we test using your actual control signals and software.

Phase 5: Production and Quality Assurance

Production units are manufactured with full traceability. Heat treat certifications, dimensional reports, and material certifications accompany each batch. Every drive—not a sample—is functionally tested before leaving our facility.

Phase 6: Post-Launch Support

Installation support, field troubleshooting, and design refinement for subsequent generations are integral to our offering. Your project does not end at shipment; it continues through the life of your machine.

Applications of Custom Slew Drives Across Industries

The versatility of the slew drive architecture means that customization unlocks applications far beyond traditional heavy lifting. At LyraDrive, our custom solutions are operating in some of the most demanding environments on earth—and beyond.

Renewable Energy: Precision Under the Sun

Solar trackers must follow the sun with consistent accuracy over decades, often in remote locations with minimal maintenance. LyraDrive custom slew drives for concentrated photovoltaic (CPV) and photovoltaic (PV) arrays feature:

Ultra-low backlash for precise positioning

Specialized seals for desert and coastal environments

Integrated encoder mounting for closed-loop control

Mobile Equipment: Strength Without Weight

Articulated dump trucks, excavators, and forestry machinery require drives that survive shock loads and continuous oscillation. Our custom solutions for mobile equipment emphasize:

High shock load capacity through optimized raceway hardening

Compact envelopes that conserve machine swing radius

Corrosion protection for undercarriage mounting

Aerial Work Platforms: Safety as Standard

Boom lifts and cherry pickers depend on self-locking drives for operator safety. LyraDrive custom slews provide:

Verified self-locking under rated load

Redundant sealing for hydraulic oil retention

Precision backlash control for smooth, jerk-free motion

Defense and Radar: Reliability in Extremes

Ground-based radar, naval fire control, and satellite communication terminals cannot tolerate positioning error or unplanned downtime. LyraDrive has supplied custom drives with:

Arctic-grade lubrication to -40°C

EMI/RFI shielding provisions

Non-magnetic material specifications

Extended storage and non-operating life requirements

Industrial Automation: Speed and Repeatability

Packaging lines, rotary index tables, and robotic positioners demand rapid acceleration and precise stopping. Custom drives from LyraDrive feature:

Low-inertia worm configurations

Precision-ground gearing for minimal backlash

High-speed input capability

Your Application

If you do not see your industry listed, consider this an invitation. LyraDrive has engineered solutions for oil and gas valve actuation, medical imaging patient positioning, amusement ride motion bases, and even theatrical stage automation. If it rotates under load, we can optimize it.

How to Select the Right Partner for Your Custom Slew Drive?

LyraDrive does not stop at customizing a single product type. We design and manufacture both custom worm gear slew drives and custom spur gear slew drives —whichever architecture best suits your load, speed, and precision requirements. Whether you need the self-locking capability of a worm drive or the higher efficiency and faster rotation of a spur gear configuration, we engineer it specifically for your application.

At LyraDrive, we view each custom project as a long-term collaboration. We are as invested in your machine's success in year ten as we are on launch day.

| Evaluation Criteria | Why It Matters | LyraDrive Commitment |

|---|---|---|

| Engineering resources | Determines if supplier can validate performance or only copy drawings | In-house design and analysis team |

| Manufacturing agility | Determines if your custom requirements cause production disruption | Flexible cells, not hard automation |

| Quality traceability | Determines if defects can be identified and corrected | Unit-level certification available |

| Application experience | Reduces design risk | Cross-industry engineering archive |

| After-sale access | Determines long-term support | Direct engineering contact |

Conclusion: Precision as the Catalyst for Innovation

Your machine is unique. Your requirements are specific. Your reputation depends on delivering performance that your competitors cannot match.

A standard slew drive may move the load, but a custom engineered slew drive from LyraDrive moves your project forward. It removes constraints. It extends service life. It transforms a commodity component into a competitive advantage.

Whether you are designing the next generation of solar tracking, heavy equipment, or specialized automation, the choice of motion partner influences everything that follows. We invite you to bring us your most challenging rotary motion problems. Together, we will engineer the solution.

LyraDrive: Engineered to move you forward.