Comprehensive Guide to Worm Gear Drive WE21-Principles, Features, and Applications

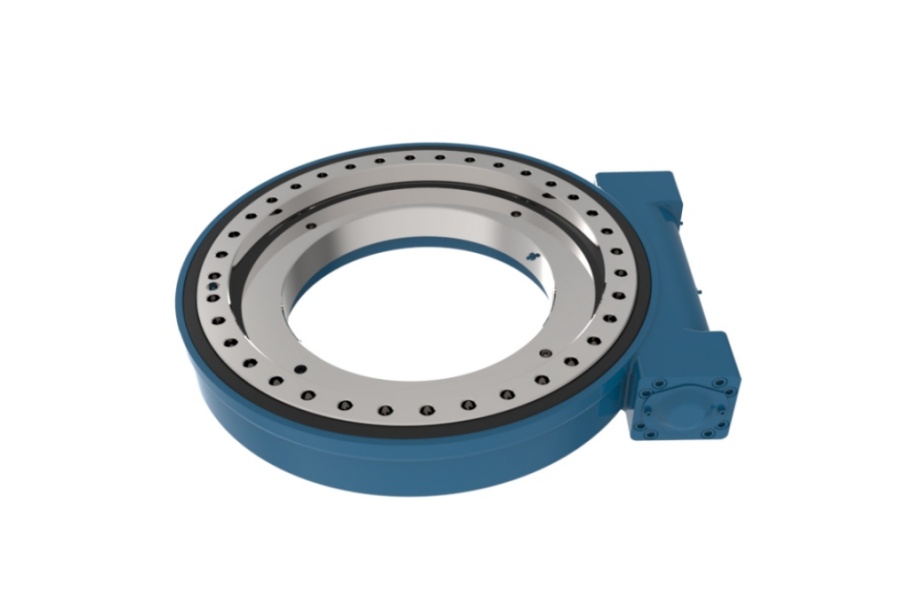

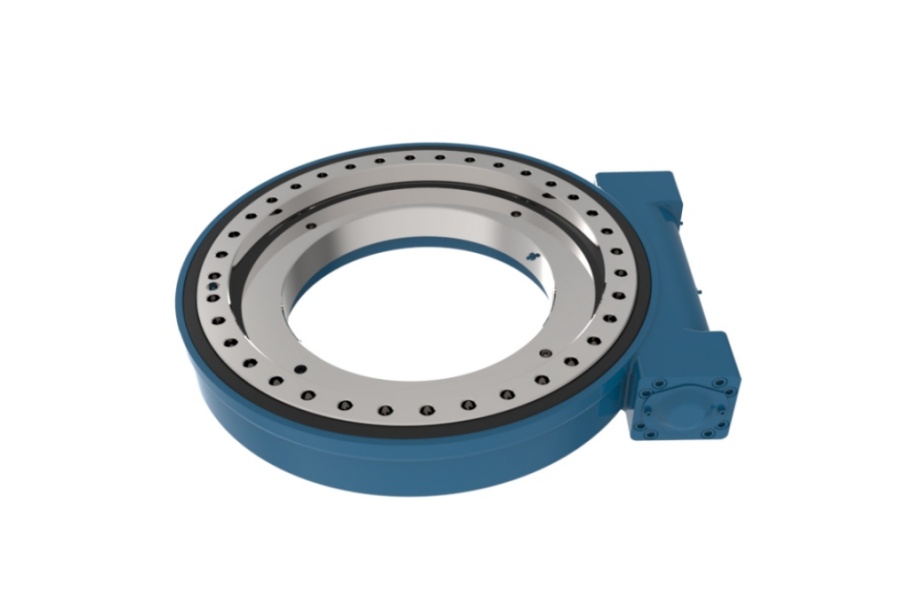

What is Worm Gear Drive WE21

Worm gear drive WE21 is a type of mechanical system consisting of a worm (a screw-like gear) and a worm wheel (a helical gear). It is designed to transmit motion and power between non-parallel, non-intersecting shafts, typically at a 90-degree angle. WE21 is known for its durability, high reduction ratio, and ability to provide self-locking functionality, making it ideal for heavy-duty applications.

WE21 Common Failures and Maintenance

Like all mechanical systems, worm gear drive WE21 can experience wear and tear over time. Common issues include overheating due to inadequate lubrication, tooth wear, and misalignment. Regular maintenance, such as proper lubrication, alignment checks, and monitoring for unusual noise or vibration, can significantly extend its lifespan. Using high-quality lubricants and ensuring correct installation are key to minimizing downtime.

The Principle of Worm Gear Drive

Worm gear drives operate on the meshing principle between the worm and the worm wheel. The worm’s helical threads engage with the teeth of the worm wheel, converting rotational motion from the worm into a slower, more powerful rotation of the worm wheel. This mechanism allows for significant speed reduction while increasing torque, making it suitable for applications requiring precise control and high load capacity.

Features of Worm Gear Drive WE21

Worm gear drive WE21 offers several distinct advantages:

High Reduction Ratio: Capable of achieving large speed reductions in a single stage.

Self-Locking Mechanism: Prevents back-driving, enhancing safety in lifting applications.

Compact Design: Saves space compared to other gear systems.

Smooth and Quiet Operation: Ideal for noise-sensitive environments.

Durability: Made from high-strength materials to withstand heavy loads and harsh conditions.

Applications of Worm Gear Drive WE21

Worm gear drive WE21 is utilized across various industries, including:

Conveyor Systems: For smooth and controlled material handling.

Lifting Equipment: In cranes and hoists due to its self-locking feature.

Automotive: For steering mechanisms and powertrain systems.

Industrial Machinery: In packaging, printing, and food processing equipment.

Robotics: For precise motion control in automated systems.

Factors Affecting the Price of Worm Gear Drive WE21

The cost of worm gear drive WE21 depends on several factors:

Material Quality: High-grade metals like bronze or hardened steel increase durability and price.

Precision and Tolerance: Higher precision gears command a premium.

Size and Specifications: Larger or custom-designed units are more expensive.

Brand and Supplier: Reputable manufacturers may charge more for reliability and after-sales support.

Order Volume: Bulk purchases often reduce per-unit costs.

Supplier of Worm Gear Drive WE21

LYRADRIVE is a trusted supplier of high-performance worm gear drives, including the WE21 series. With years of expertise in power transmission solutions, LYRADRIVE offers reliable products, technical support, and customized solutions to meet diverse industrial needs. Their commitment to quality ensures long-lasting performance and customer satisfaction.