Applications of Spur and Worm Gear Slew Drives

Introduction

Slew drives are the fundamental mechanical nexus where high torque meets controlled rotation in heavy-duty applications. The choice between spur and worm gear configurations is not merely a matter of preference, but a critical engineering decision that hinges on load dynamics, operational safety, efficiency requirements, and environmental factors. This comprehensive guide delves into the mechanical principles, comparative advantages, and specific application terrains of both drive types to inform your design and selection process.

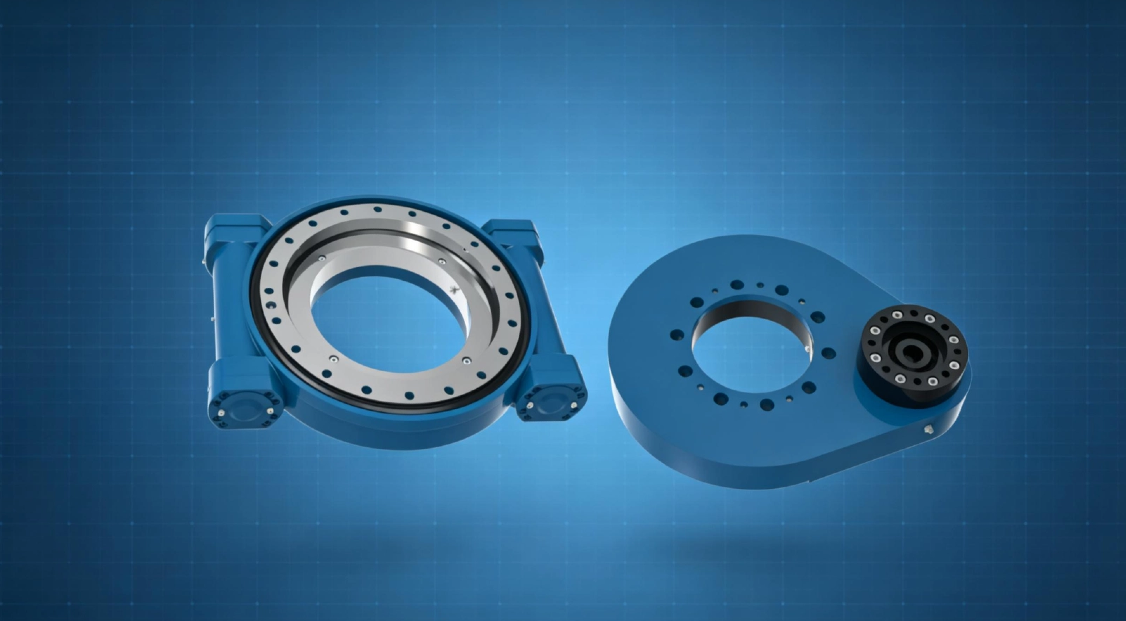

What is Spur Slew Drive?

A spur slew drive is a robust integrated assembly that combines a slewing bearing with a coaxial spur gear and a mating pinion. Its defining characteristic is the use of straight-cut spur gears, where the teeth are parallel to the axis of rotation. This geometry facilitates direct, linear contact between the pinion and the gear teeth, resulting in exceptionally high mechanical efficiency, often exceeding 95%. The design inherently handles substantial axial and radial loads transferred through the bearing, while the gearset efficiently manages the driving torque. Its construction is notably compact, as the power transfer occurs in the same plane as the rotation, minimizing the overall envelope.

How Does Spur Slew Drive Work?

The operational principle is elegantly simple yet powerful. A hydraulic motor or electric servo directly drives the input pinion shaft. As the pinion rotates, its teeth engage with the larger spur gear’s teeth in a rolling action. This engagement accomplishes two key functions: speed reduction and torque multiplication. The reduction ratio is determined by the number of teeth on the spur gear versus the pinion. For instance, a 150-tooth gear driven by a 15-tooth pinion yields a 10:1 reduction ratio. The output is a powerful, smooth rotational force applied directly to the mounted structure. The absence of sliding friction (predominant in other gear types) during primary power transmission is the core reason for its high efficiency and suitability for continuous, high-cycle operations.

Application of Spur Slew Drives

Spur slew drives dominate applications where operational efficiency, higher rotational speed, and lower power consumption are paramount. Their lack of inherent self-locking necessitates external braking systems but allows for free rotation when disengaged.

Solar Tracking Systems: Here, efficiency directly translates to energy yield. Spur drives minimize parasitic power loss from the tracker's motors, allowing more energy to be fed into the grid. Their ability to handle the slow, precise, and continuous daily rotation makes them ideal.

Wind Turbine Yaw and Pitch Control: In pitch systems, they adjust blade angles for optimal wind capture or storm protection. Their reliability and responsiveness are critical for maximizing energy production and protecting multi-million-dollar assets.

Light to Medium-Duty Industrial Rotators: This includes assembly line turntables, welding positioners, and material handling equipment. The need for precise indexing, repeatability, and long service life with minimal maintenance aligns perfectly with the spur drive's strengths.

What is Worm Slew Drive?

A worm gear slew drive operates on a fundamentally different principle, utilizing a worm screw (a helical threaded shaft) meshing with a worm wheel (a gear resembling a spur gear but with teeth curved to envelop the worm). The key distinction lies in the 90-degree axis intersection between the worm and the wheel. This geometry creates a sliding contact between the gear teeth, which naturally generates higher friction, reduces efficiency (typically 50-90%), but grants the priceless benefit of irreversibility or self-locking. When the input stops, the friction prevents the output load from back-driving the system. They are categorized into:

Single Worm Drives: The standard configuration, offering a compact solution with excellent self-locking and a wide range of reduction ratios in a single stage.

Double Worm Drives: An engineering enhancement featuring two worms, 180° apart, engaging the same wheel. This design is not merely about doubling power; it’s about load sharing, backlash elimination, and unparalleled system rigidity.

How Does Worm Slew Drive Work?

In a single worm drive, the motor rotates the worm, whose threads push against the faces of the worm wheel teeth. This action produces a high reduction ratio—determined by the number of threads on the worm (starts) and teeth on the wheel—and substantial torque multiplication. The point contact, however, can lead to wear and inherent backlash.

The double worm drive revolutionizes this concept. The two opposing worms pre-load the worm wheel, effectively eliminating all functional backlash. This creates a mechanically locked system with exceptional torsional stiffness. Furthermore, the load is distributed across two contact zones, drastically reducing tooth pressure, minimizing wear, and extending service life. It also provides redundancy; should one worm fail, the other can often maintain controlled operation, a critical feature for safety in heavy lifting.

Application of Worm Gear Slew Drives

Worm drives are the workhorses of industries where holding security, shock load resistance, and high torque in a compact package are non-negotiable.

Single Worm Drives are deployed in:

Mobile Construction Equipment: Excavator swing drives, where the self-locking feature safely holds the cab and arm in position without constant hydraulic pressure.

Agricultural Machinery: In large irrigation pivots or manure spreaders, where reliable, maintenance-friendly rotation in dirty environments is key.

Communication Antennas: Providing stable positioning that won't drift due to wind or weight.

Dual Worm Drives are specified for the most demanding tasks:

Heavy-Lift Offshore and Port Cranes: Handling thousands of tons requires absolute positional stability and zero backlash to prevent load swing. The dual-worm system provides the rigidity and safety factor needed.

Advanced Military and Aerospace Systems: Turret drives for weapon systems or radar pedestals demand micron-level precision, extreme reliability, and resistance to shock loads from firing or maneuvering.

High-Concentration Solar (CSP) and Large-Scale PV Plants: The immense size and wind loading of these structures require drives with ultimate precision to focus sunlight and the strength to withstand environmental forces.

LyraDrive: Professional Slew Drive Manufacturer

At LyraDrive, we move beyond standard manufacturing to become a solutions partner in motion control. Our engineering process begins with a thorough analysis of your application’s load spectrum, duty cycle, environmental harshness, and lifecycle goals.

Spur Drive Solutions: We optimize gear geometry for quiet operation and longevity, select bearing configurations for combined loads, and integrate high-efficiency sealing systems.

Worm Drive Expertise: We offer a range from cost-effective single worms to our flagship DualTork™ series, engineered for zero-backlash and maximum durability. Material science is key—we use case-hardened and ground alloy steels for worms and phosphor bronze or specialty alloys for wheels to optimize the sliding interface.

Full Customization: Whether you need a flange-mounted, hollow-shaft, or motor-integrated design, with specific IP ratings, corrosion protection (e.g., UTL-3 coating), or extreme-temperature lubricants, our design-to-order capability ensures the drive is an integral part of your system's success.