Application Of Large Size Slewing Ring

Large size slewing rings, also known as slewing bearings, are the unsung heroes behind the motion of our modern world's most massive and impressive machinery. These robust, precision-engineered components are not just bearings; they are integrated systems that enable controlled, heavy-duty rotation where it's needed most. This article explores what they are, how they work, and their vital role across diverse industries.

What is Slewing Ring?

A slewing ring is simply another name for a slewing bearing. The terms are interchangeable and refer to the same product: a large-diameter, ready-to-mount bearing that acts as a 360-degree rotating joint. Its defining characteristic is its ability to simultaneously handle combined loads—axial (thrust), radial, and tilting moment loads—all within a single, compact unit. This integrated design makes it the fundamental component for connecting and rotating large structures.

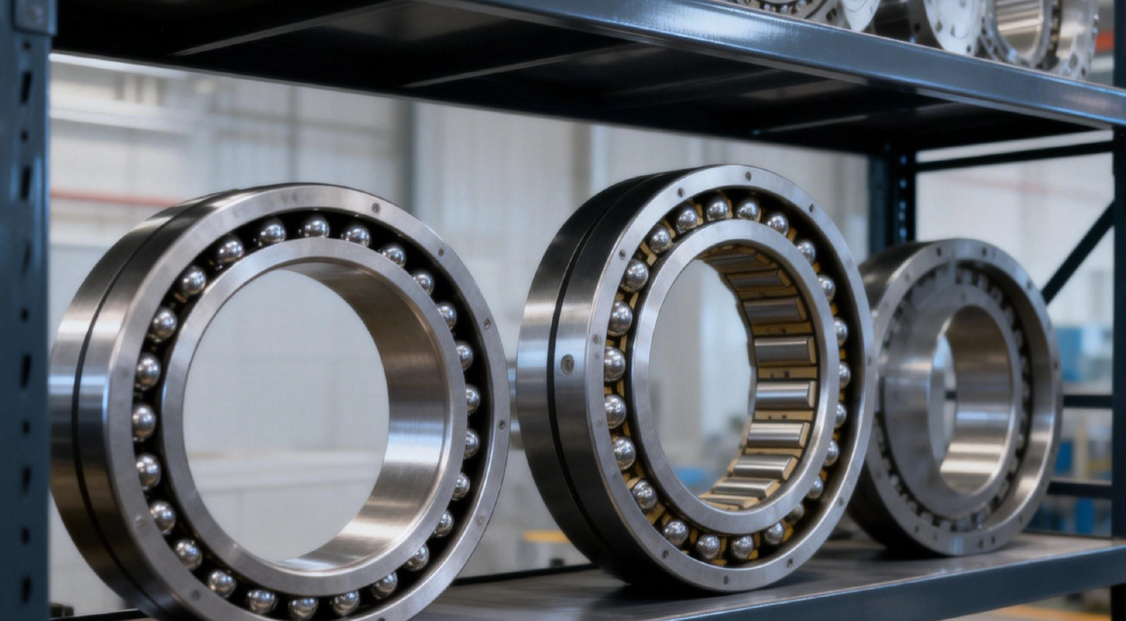

What are the Different Types of Slewing Bearings?

Slewing bearings are not one-size-fits-all. They are engineered in several configurations to excel under specific load conditions. The main types are defined by their internal rolling elements and raceway arrangement:

Single Row Ball Slewing Bearing: The most common type, using a single row of balls. It efficiently handles combined axial and radial loads and is known for its high precision and smooth operation, making it ideal for applications like solar trackers and light-to-medium duty cranes.

Double Row Ball Slewing Bearing: Features two independent rows of balls. This design provides a much higher load capacity, particularly for tilting moments (overturning forces). It's the go-to choice for more demanding equipment like large excavators and container cranes.

Crossed Roller Slewing Bearing: Uses cylindrical rollers arranged in a single row at a 90-degree cross pattern. This design offers extremely high precision and rigidity, with an exceptional capacity for moment loads relative to its size. It's often found in high-precision industrial robots, radar bases, and medical imaging equipment.

Three Row Roller Slewing Bearing: The heavyweight champion. It uses three separate rows of rollers—one for axial loads and two for radial loads. This configuration delivers the highest possible load capacity and is exclusively used in the most extreme applications, such as the swing mechanisms of giant mining excavators and heavy-duty offshore cranes.

How Does Slewing Bearing Work?

The principle is elegant yet powerful. A slewing bearing is installed between two structures that need to rotate relative to each other, such as a crane's upper cab and its fixed undercarriage. The bearing's inner and outer rings are bolted to these respective structures. Inside, precision-machined raceways guide the rolling elements (balls or rollers).

When a drive system (usually a motor turning a small pinion gear) engages with the gear teeth integrated on the bearing's ring, it causes the rings to rotate against each other. The rolling elements minimize friction, allowing the entire attached structure to swing or slew smoothly and with control, even under thousands of tons of load.

Application Types of Slewing Bearings in Different Fields

The unique ability of slewing bearings to handle massive, complex loads makes them indispensable across a wide range of industries. Below is an overview of their critical applications in several key sectors.

1. Renewable Energy

In the push for sustainable power, slewing bearings provide the precise motion control essential for efficiency.

Typical Machinery: Wind Turbines, Solar Trackers

Primary Function:

(1) In Wind Turbines: They are at the heart of the yaw system (rotating the nacelle to face the wind) and the pitch system (adjusting the angle of each blade to optimize power and manage loads).

(2)In Solar Trackers: They enable solar panels to accurately follow the sun's path throughout the day, significantly increasing energy capture compared to fixed installations.

2. Construction & Mining

This sector relies on slewing bearings to provide the powerful, reliable rotation needed for the world's heaviest machinery.

Typical Machinery: Mobile Cranes, Excavators, Tunnel Boring Machines (TBMs)

Primary Function: They provide the essential 360-degree swing function for crane booms and excavator upper structures. In massive TBMs, they facilitate the steering and stabilization of the rotating cutting head as it bores through rock and soil.

3. Material Handling

For moving massive loads quickly and safely, slewing bearings are a key enabling technology.

Typical Machinery: Port Cranes (Ship-to-Shore), Stacker Reclaimers

Primary Function: In port cranes, they enable the rotating and luffing motions of the boom to efficiently load and unload container ships. In bulk material yards, they allow stacker-reclaimers to slew and travel across vast stockpiles.

4. Defense & Aerospace

Applications in this field demand exceptional precision, reliability, and often, operation in harsh conditions.

Typical Machinery: Radar Antennas, Satellite Communication Dishes

Primary Function: Slewing bearings provide the smooth, stable, and precise rotational platform required for long-range detection, targeting, and communication. They ensure antennas and dishes can track objects or maintain satellite links accurately.

5. Industrial Manufacturing

Here, slewing bearings drive automation, precision, and productivity in heavy-duty processes.

Typical Machinery: Welding Positioners, Heavy-Duty Turntables, Indexing Tables

Primary Function: They provide precise rotational positioning for heavy workpieces, allowing for automated welding, assembly, machining, and inspection from optimal angles, thereby improving quality, consistency, and worker safety

LyraDrive Offers the Slewing Bearings You Need, Along with Expert Selection Advice

Selecting the right slewing bearing is a critical decision that impacts the performance, safety, and total cost of ownership of your equipment. It's not just about size and price; it's about matching the bearing's type, gear configuration, sealing, and material to your specific load spectrum, rotational speed, and operating environment.

This is where LyraDrive provides unmatched value. We are more than a manufacturer; we are your technical partner. Our team of application engineers works closely with you to analyze your requirements and recommend the optimal slewing bearing solution. We combine our extensive product range with deep engineering expertise to ensure you get a component that delivers reliability, longevity, and peak performance.

Partner with LyraDrive. Let us help you select and supply the precise slewing bearing that forms the robust, rotating foundation for your machine's success