A Comprehensive Guide on How to Purchase a Slewing Bearing

What is a Slewing Bearing?

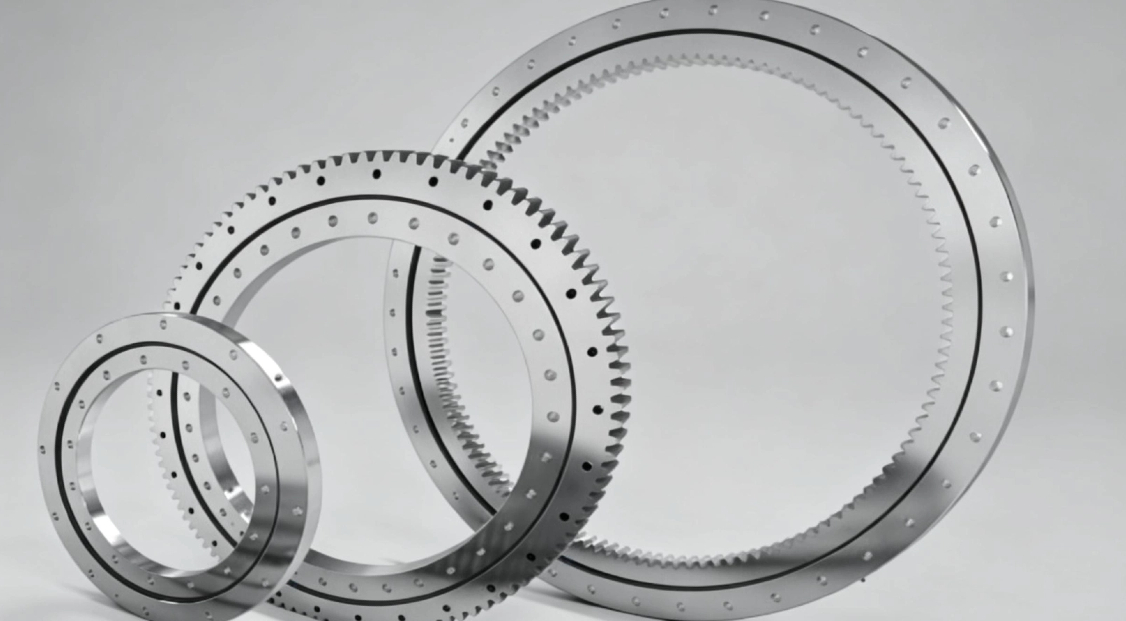

A slewing bearing, also known as a turntable bearing or slewing ring, is a large-scale rolling-element bearing designed to handle heavy axial, radial, and moment loads simultaneously. Unlike standard bearings, slewing bearings enable smooth rotational movement between two machine components, such as a crane’s upper structure and its base, or an excavator’s house and undercarriage. They are essential for enabling controlled, 360-degree rotation in heavy-duty applications.

Features of Slewing Bearings

Slewing bearings are characterized by several key features:

High Load Capacity: Designed to support combinations of axial, radial, and tilting moment loads.

Integrated Design: Often include mounting holes, gear teeth (internal or external), and sealing systems for easy integration into machinery.

Compact Structure: Provides a space-saving solution for rotational movement compared to multiple standard bearings.

Durability: Manufactured from high-quality steel and heat-treated for wear resistance and long service life.

Smooth Operation: Precision-engineered rolling elements (balls or rollers) and raceways ensure low-friction rotation.

Applications of Slewing Bearings

Slewing bearings are versatile components used across various industries:

Construction Machinery: Excavators, cranes, concrete pumps, and pile drivers.

Wind Energy: Pitch and yaw systems in wind turbines.

Industrial Equipment: Robotic arms, material handling systems, and welding positioners.

Renewable Energy: Solar tracking systems.

Defense & Aerospace: Turrets, radar systems, and satellite antennas.

Medical Equipment: CT scanners and surgical platforms.

Types of Slewing Bearings

Selecting the right type is crucial for optimal performance:

Single-Row Ball Slewing Bearings: Suitable for moderate loads and high rotational speed applications.

Double-Row Ball Slewing Bearings: Offer higher load capacity and rigidity compared to single-row designs.

Crossed Roller Slewing Bearings: Use cylindrical rollers arranged at 90° angles, providing high precision and moment load capacity.

Three-Row Roller Slewing Bearings: Ideal for extremely heavy loads, commonly used in heavy cranes and mining equipment.

Wire Race Slewing Bearings: Feature raceways made from hardened steel wire, excellent for very slow, heavily loaded applications like swing bridges.

Factors to Consider When Selecting a Slewing Bearing

Making the right choice for your slewing bearing is critical to the performance, longevity, and safety of your entire machine. This decision requires a detailed evaluation of both technical specifications and real-world operational demands. Below are the key factors to consider, explained in greater detail.

1. Load Requirements

This is the most fundamental consideration. You must go beyond just listing types of loads and quantify them precisely.

Axial Load (Thrust Load): The force parallel to the bearing's axis of rotation (e.g., the weight of a wind turbine nacelle pushing down). Calculate the maximum static and dynamic axial forces.

Radial Load: The force acting perpendicular to the axis (e.g., the horizontal force on a crane boom). Understand its magnitude and point of application.

Moment Load (Overturning Moment): This is the tilting force that attempts to "capsize" the bearing (e.g., the load on an excavator arm creating a powerful leverage effect). This is often the most critical load. Accurately calculate the maximum tilting moment (usually in kN·m or ft·lbs) from all operational and potential overload scenarios.

Load Combination: Slewing bearings almost always experience a combination of these loads simultaneously. Provide your supplier with the worst-case load combination your application will face. Dynamic shock loads (like digging impacts) must also be specified.

2. Size and Dimensions

Dimensions are not just about fit; they determine load capacity and structural integration.

Bore Diameter: Dictates the size of the central shaft or structure. Ensure sufficient clearance for any central components (hydraulic rotors, wiring).

Outer Diameter: Limited by the available space in your machine's design. A larger OD generally allows for higher load capacity.

Height/Thickness: Impacts the bearing's cross-section and stiffness. A thicker bearing can handle higher moment loads.

Mounting Arrangement: Precisely define the bolt hole pattern (PCD - Pitch Circle Diameter), bolt size, quantity, and thread type (through-hole vs. tapped holes). Specify if you require dowel holes for precise alignment and anti-shear protection.

3. Gear Configuration

The gear is integral for motor-driven rotation. Its specification directly affects drive system performance.

Gear Type: External gears are common and easier to mesh with a pinion. Internal gears offer a more compact drive arrangement and protected gear teeth.

Gear Specifications:

Module (or Diametral Pitch): This defines the tooth size. A larger module means stronger teeth for higher torque transmission.

Number of Teeth: Affects the gear ratio with the driving pinion.

Accuracy Class: Specifies the gear's manufacturing precision (e.g., DIN 10). Higher accuracy ensures smoother, quieter operation and longer pinion life.

Hardening: Gear teeth are typically hardened (induction or flame) for wear resistance, while the tooth root may be left tougher to absorb shock.

4. Material and Heat Treatment

This is the foundation of bearing durability.

Base Material: High-quality, vacuum-degassed alloy steel like 50Mn or 42CrMo4 is standard. The former offers good overall performance; the latter provides superior toughness for high-impact applications.

Heat Treatment: Raceways and gear teeth undergo surface hardening.

Raceways: Usually induction hardened to a depth of 4-6mm, achieving a hardness of 55-60 HRC to withstand rolling contact fatigue.

Core Toughness: The material's core remains softer (around 250-300 HB) to maintain structural integrity and resist cracking under high loads.

5. Sealing and Lubrication

This system protects the bearing's interior and ensures smooth operation over time.

Seals: Specify based on environment. Rubber seals (NBR or FKM) are standard for general use. For extreme conditions, consider labyrinth seals (multi-path barriers against dust/water) or special compound seals for high temperatures or chemical exposure.

Lubrication: Define the lubrication system. Grease nipple fittings are common. Specify the grease type (e.g., lithium-based EP grease). For large bearings or harsh conditions, request a centralized lubrication system with multiple distribution points and potentially re-lubrication grooves to ensure grease reaches all rolling elements.

6. Accuracy and Clearance

These parameters control the "feel" and stiffness of the rotation.

Internal Clearance (Play): The internal gap between rolling elements and raceways. Standard clearance is suitable for most applications. Zero or Preload clearance reduces axial/radial play for applications requiring high rigidity and precise positioning (e.g., robotics, machining tables) but increases friction and requires precise installation.

Running Accuracy: Defines tolerances for axial/radial runout and parallelism of mounting surfaces. Higher accuracy classes are needed for smooth, low-vibration operation in precision equipment.

7. Environmental Conditions

The operating context dictates material and design choices.

Temperature: Standard bearings are rated for -25°C to +80°C. For applications outside this range (e.g., Arctic machinery, furnaces), specify low-temperature impact-tested steels or high-temperature stabilized seals and greases.

Corrosion: For marine, offshore, or chemical environments, specify corrosion protection such as zinc plating, Dacromet coating, or even stainless steel components. Increased sealing is also crucial.

Contamination: In mining or construction with heavy dust/slurry, request heavy-duty, multi-layered sealing systems and consider protecting the gear teeth with a cover.

Special Conditions: Inform the supplier of any exposure to chemicals, salt spray, abrasives, or potential electrical currents (which can cause arcing damage).

Steps to Purchasing a Slewing Bearing

Follow this systematic process for a successful purchase:

Define Your Requirements: Clearly outline your application’s load demands, dimensions, operating conditions, and desired features.

Select the Type: Based on your analysis, choose the most suitable slewing bearing type (e.g., single-row ball, crossed roller).

Request a Quotation: Provide detailed specifications to potential suppliers, including drawings if available.

Evaluate Manufacturers: Assess suppliers based on their manufacturing capabilities, quality certifications (e.g., ISO 9001), industry experience, and technical support.

Review the Proposal: Scrutinize the offered bearing design, material specifications, warranty, delivery timeline, and pricing.

Place a Sample Order (If Needed): For critical applications, consider ordering a prototype or sample for testing before full-scale procurement.

Finalize the Order: Confirm technical details, payment terms, delivery schedule, and after-sales service agreement.

LyraDrive: A Reliable Slewing Bearing Manufacturer

For a trusted supply partner, consider LyraDrive. As a leading manufacturer, LyraDrive offers:

Custom Engineering: Ability to design and produce bearings tailored to specific customer requirements.

Advanced Manufacturing: State-of-the-art facilities with CNC machining, induction hardening, and rigorous quality control.

Wide Range: Production of all major slewing bearing types in various sizes.

Quality Assurance: Each bearing undergoes strict inspection to ensure durability and performance.

Global Support: Provides expert technical consultation, reliable after-sales service, and timely delivery worldwide.

FAQ about How to Purchase a Slewing Bearing

Q: Can I replace a standard bearing with a slewing bearing?

A: Slewing bearings are specialized components designed for combined loads and rotation. They are not direct replacements for standard bearings. Consult an engineer to redesign the assembly if necessary.

Q: How do I determine the load capacity I need?

A: Calculate or simulate all forces (axial, radial, moment) acting on the bearing in your application. A qualified engineer or the bearing manufacturer’s technical team can assist with this analysis.

Q: Are custom-designed slewing bearings available?

A: Yes, reputable manufacturers like LyraDrive offer custom design services for non-standard dimensions, special materials, unique gear profiles, or integrated features.

Q: What is the typical lead time for ordering?

A: Lead time depends on complexity, size, and quantity. Standard bearings may be available from stock, while custom designs can take several weeks. Always confirm timelines with your supplier.

Q: How important is maintenance for slewing bearings?

A: Extremely important. Regular lubrication and inspection of seals and gear teeth are essential to prevent premature failure and ensure long service life. Follow the manufacturer’s maintenance guidelines.