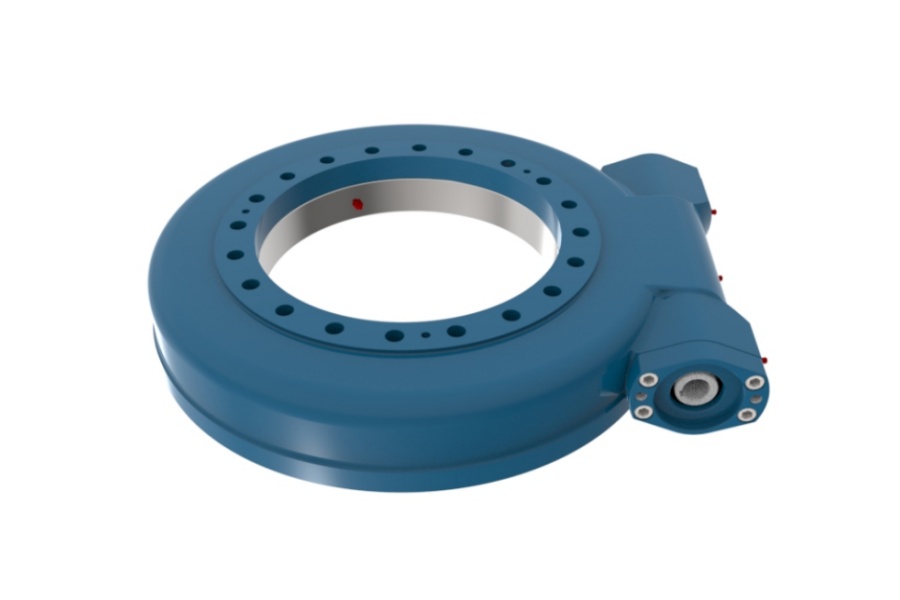

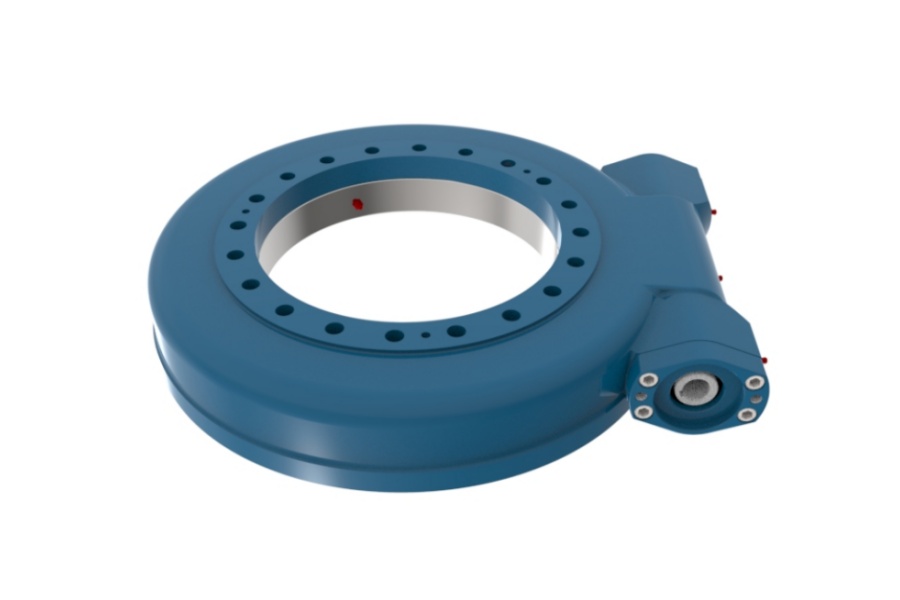

Worm Gear Slew Drive Lubrication Procedures

What is Worm Gear Slew Drive

Worm Gear Slew Drive integrates a precision worm reducer with a slewing bearing into a compact unit. The input worm shaft engages with gear teeth on the bearing’s inner/outer ring, converting high-speed rotation into high-torque, low-speed output. Its self-locking capability and sliding contact mechanics demand specialized lubrication protocols to minimize wear and heat generation.

How to Lubricate Worm Gear Slew Drives

Step 1: Lubricant Selection Criteria

Temperature Range:

-30°C to +80°C: ISO VG 320 synthetic PAO oil with 5% MoS₂

>100°C: Fluorinated grease (PFPE base) with PTFE thickener

Arctic (-50°C): Silicone-based grease (viscosity index >200)

Speed Factor:

High Speed (>100 rpm): NLGI 0 grease (penetration 355-385)

Low Speed (<10 rpm): NLGI 2 grease (penetration 265-295)

Load Intensity:

Shock Loads: EP additives (ZDDP ≥1.2%)

Continuous >80% load: Polymer-complex greases with 10% solid lubricants

Material Compatibility:

Bronze gears: Non-reactive sulfonate greases (TBN <5)

Stainless steel: Chlorine-free formulations (Cl⁻ <50ppm)

Step 2: Volume Calculation & Injection

Formula: *V = 0.114 × D × W*

V: Grease volume (cm³)

D: Bearing pitch diameter (mm)

W: Bearing width (mm)

Dynamic Lubrication Protocol:

Rotate drive at 1-2 rpm during injection

Inject grease at 50-70 bar pressure

Stop when fresh grease extrudes from all seal lips

Wipe excess immediately

Step 3: Interval Optimization

Baseline Formula: *I (hours) = [K × 10⁶] / (n × √P)*

K: Application factor (0.8 for solar, 1.2 for cranes)

*n*: Average RPM

P: Equivalent dynamic load (kN)

Condition-Based Monitoring:

Grease dielectric constant >3.5: Degradation threshold

Fe content >200ppm: Wear alert

Step 4: Contamination Control

Cleaning Before Relubrication:

Flush with ISO VG 22 flushing oil (3% of cavity volume)

Rotate through 10 full cycles

Seal Maintenance:

Replace triple-lip seals every 5,000 operating hours

Worm Gear Slew Drive Characteristics

Sliding Contact: 85% mechanical efficiency at best

Self-Locking: Static holding ratio ≥1:50

Thermal Sensitivity: 40% torque reduction at 80°C

IP69K Sealing: Standard for washdown environments

Applications

Solar Trackers: Azimuth/elevation axes (5-25 rpm)

Crane Slewing: 90-300 kNm systems

HVAC Dampers: Continuous 24/7 operation

Stage Machinery: Precision positioning

Price Influencing Factors

Sealing System: IP69K adds 22% vs IP54

Thermal Management: Integrated cooling fins +15%

Gear Quality: Ground worms (DIN 5) cost 30% more than milled

Lubrication Ports: Auto-lube ready +8%

Worm Gear Slew Drive Supplier

LYRADRIVE integrates laser-drilled micro-reservoirs in gear teeth for continuous lubricant replenishment and PTFE-encapsulated seal labyrinths reducing grease consumption by 40%. Our drives feature real-time grease condition monitoring ports compatible with IoT sensors.