Heavy Load Slewing Bearing Failure Analysis

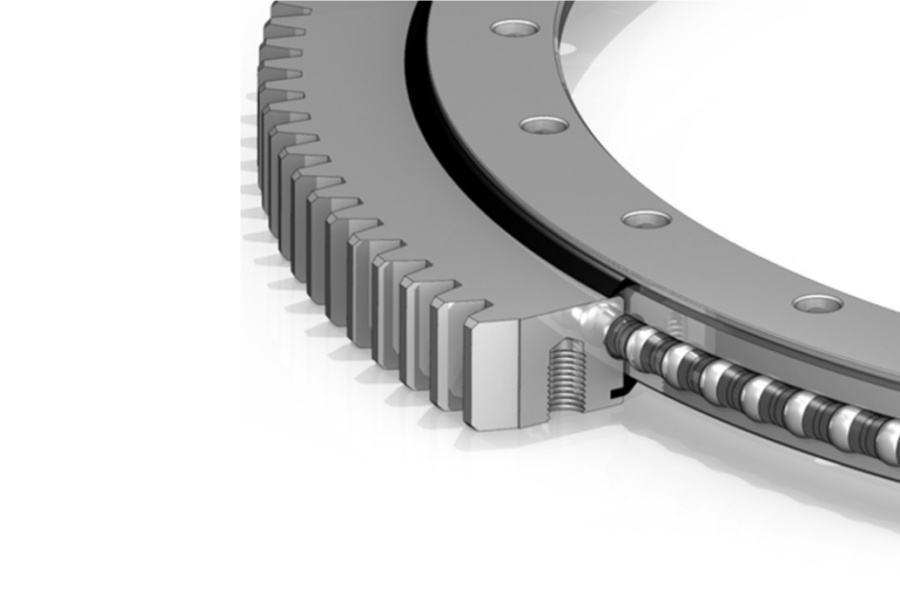

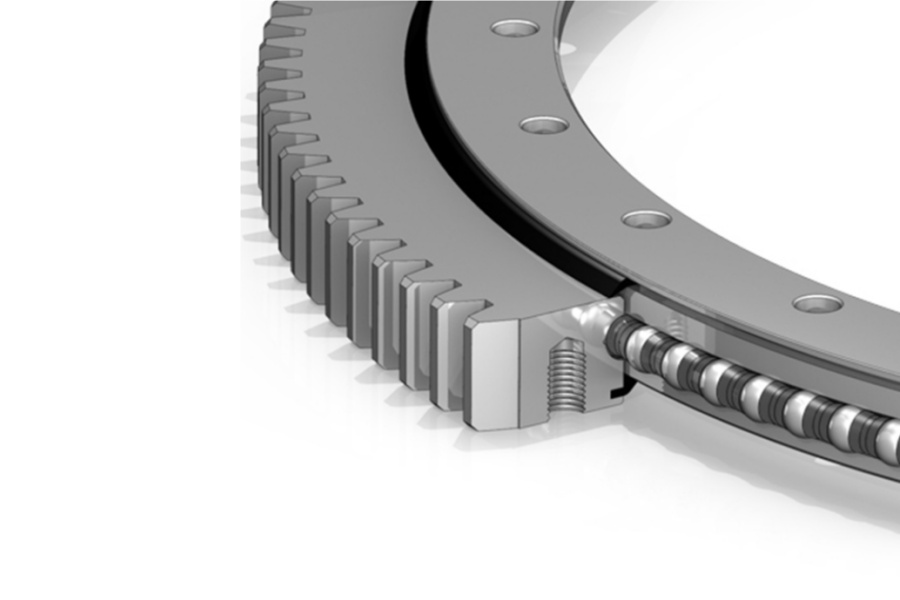

What is Heavy Load Slewing Bearing

Heavy Load Slewing Bearing is an engineered rotational component designed to withstand extreme combined loads (>1,000 kN axial, >500 kN radial, >5,000 kN·m tilting moments). Characterized by multi-row roller configurations (typically three-row cylindrical rollers), thick-section alloy steel rings (≥100mm), hardened raceways (58-62 HRC), and IP69K sealing, it serves as the critical rotation interface in mining, offshore, and heavy construction machinery.

Heavy Load Slewing Bearing Failure Analysis

Plastic Deformation & Brinelling

Cause: Static overload exceeding material yield strength (e.g., 42CrMo: 1,100 MPa). Common during shock loading or improper jacking.

Symptoms: Visible dents (>0.5mm deep) in raceways, increased rotational torque.

Diagnosis: Dye penetrant inspection; measure dent depth with profilometer.

Fatigue Spalling (Subsurface-Initiated)

Cause: Cyclic stresses surpassing material endurance limit (e.g., <600 MPa for 50Mn steel). Accelerated by:

Insufficient case hardening depth (<5% roller diameter)

Retained austenite >15%

Inclusions (TiN, Al₂O₃) near raceway subsurface

Symptoms: Flaking (1-5mm scale) in load zones, metallic debris in grease.

Diagnosis: Vibration analysis (acceleration >4g RMS); ferrography.

Corrosion-Induced Pitting

Cause: Chloride/SO₂ ingress through compromised seals. Pits act as stress concentrators (Kt≥3).

Symptoms: Brown residue, 0.1-2mm diameter pits in non-load zones.

Diagnosis: Ultrasonic thickness testing; electrochemical impedance spectroscopy.

Gear Tooth Fracture

Cause:

Root bending stress >1,500 MPa (AGMA 2004)

Improper heat treatment (case/core hardness mismatch >15 HRC)

Misalignment (>0.1° per meter)

Symptoms: Broken teeth fragments; abnormal drive noise.

Diagnosis: Gear profile scanning; residual stress measurement (XRD).

Bolt Fracture & Fretting

Cause:

Insufficient preload (<70% bolt yield strength)

Dynamic loosening under 5-10Hz vibration

Galvanic corrosion (e.g., carbon steel bolt vs stainless flange)

Symptoms: Bolt head shearing; elliptical wear marks around holes.

Diagnosis: Bolt tension monitoring; fretting scar depth measurement.

Root Cause Methodology:

Load Spectrum Analysis: Compare actual FEA load distribution vs design

Metallography: Examine case depth (per ISO 2639), inclusion rating (ASTM E45)

Lubricant Analysis: Water content >1,000 ppm indicates seal failure

Heavy Load Slewing Bearing Characteristics

Multi-Row Rollers: 3-row cylindrical rollers + 2-row balls for combined load sharing

Ultra-High Rigidity: Ring stiffness >10⁹ N/m to limit elastic deformation <0.1mm

Preloaded Design: Negative clearance (-0.05 to -0.1mm) eliminates operational backlash

Advanced Sealing: Triple-lip HNBR seals with particle exclusion labyrinths

Material Science: Vacuum-degassed 50Mn steel with directional forging

Applications of Heavy Load Slewing Bearing

Mining: Bucket wheel excavators (20,000+ kN·m moments)

Offshore: Floating crane slew rings (DNV-GL certified)

Energy: 15MW wind turbine yaw systems

Tunnel Boring: Main bearing thrust loads >12,000 kN

Port Cranes: Boom foot bearings handling 2,000t loads

Price Influencing Factors

Material Cost: 50Mn directional forging adds 35% vs standard 42CrMo

Heat Treatment: 8mm case depth carburizing (+40% vs 4mm)

Precision Grinding: Raceway profile tolerance ±0.03mm (+25% cost)

Testing: Full-scale prototype overload test (200% rating) adds 18%

Certifications: API 8C/ISO 17566 compliance premium: 15-22%

Sealing: Pressurized grease purge system: +12%

Heavy Load Slewing Bearing Supplier LYRADRIVE

LYRADRIVE engineers ISO 281 L10 life-optimized slewing bearings featuring 8-12mm case depths via deep-vacuum carburizing and -196°C cryogenic stabilization to achieve retained austenite <8%. Our proprietary directional grain flow forging enhances fatigue strength by 30% under 25,000 kN·m moments, validated through 10,000-hour accelerated life testing per ISO 17566.

Effective failure prevention requires material science mastery (vacuum-degassed 50Mn steel), precision hardening (case depth = 5-8% roller diameter), and advanced sealing (ΔP>5kPa purge systems). While premium bearings command 25-40% cost premiums, they reduce unplanned downtime by up to 90% in critical applications. For mine excavators or offshore cranes where bearing replacement costs exceed $500k, partnering with metallurgically-advanced suppliers like LYRADRIVE delivers demonstrable ROI through extended service intervals.