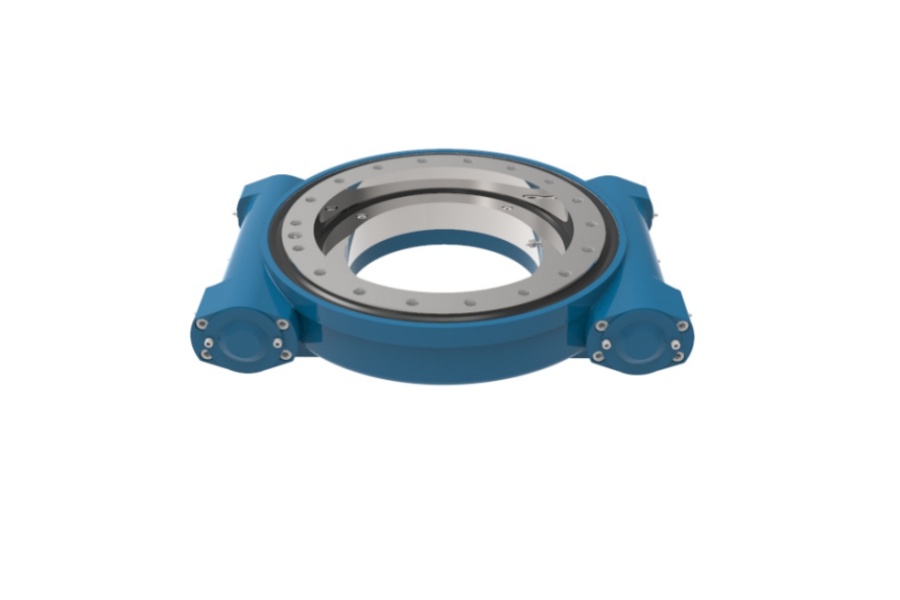

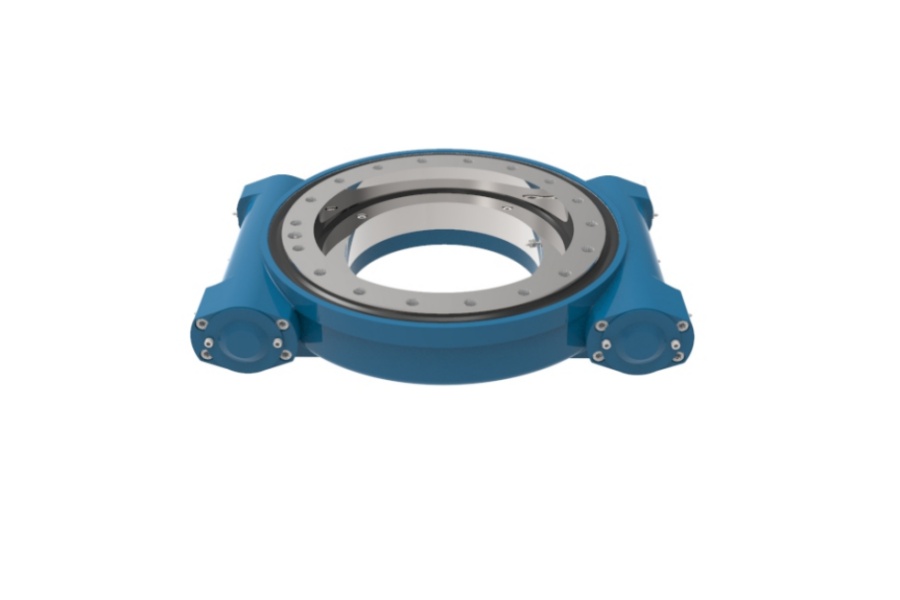

Double Worm Slew Drive Corrosion Protection Design

What is Double Worm Slew Drive

Double Worm Slew Drive integrates two parallel worm gear sets driving a single output gear (slewing ring), providing redundant torque transmission and enhanced load-sharing capability. This design offers higher reliability, smoother operation under uneven loads, and inherent safety redundancy compared to single-worm systems. Its robust housing encapsulates hardened steel worms, bronze gear wheels, and precision bearings for heavy-duty industrial rotation.

Corrosion Protection Design for Double Worm Slew Drives

Corrosion is a primary failure mode in marine, offshore, and chemical environments. LYRADRIVE employs a multi-layered defense strategy:

Surface Preparation & Base Protection:

Abrasive Blasting (Sa 2.5): Housing surfaces undergo controlled grit blasting to achieve ISO 8501-1 Sa 2.5 cleanliness (near-white metal), ensuring optimal coating adhesion.

Zinc-Nickel Electroplating (Zn-Ni): Critical steel components (housing, bolts) receive 15-25μm Zn-Ni coating (ISO 19598). This alloy offers 5x the corrosion resistance of standard zinc plating (720h salt spray vs. 120h per ASTM B117).

Hot-Dip Galvanizing (HDG): For structural housings in extreme environments, 85-120μm HDG coating (ISO 1461) provides robust sacrificial protection.

Advanced Seal Architecture:

Triple-Lip Radial Shaft Seals: FKM (Viton®) elastomers with stainless steel tension springs resist saltwater, UV, and chemicals.

Labyrinth Pathways: Multi-stage dust/water exclusion channels with grease purging ports.

IP69K-rated Housing Seals: High-pressure washdown-resistant gaskets at housing joints.

Corrosion-Resistant Material Selection:

Worm Wheels: Aluminum bronze (C95400/C95800) inherently resists seawater corrosion and dezincification.

Fasteners: A4 (316L) stainless steel bolts with Dacromet® coating.

Bearings: Stainless steel (440C) or ceramic hybrid options.

Protective Coatings & Treatments:

Epoxy-Polyurethane Topcoat: 80-120μm thick, chemically resistant coating (ISO 12944 C5-M class) applied over Zn-Ni/HDG. Colors rated for 10+ years UV resistance.

Internal Cavity Wax: VCI (Vapor Corrosion Inhibitor) wax injected into internal voids.

Black Oxide (for Assembly): Non-critical internal steel parts receive black oxide coating for in-process protection.

Packaging & Storage Protocols:

VCI Film Wrapping: Drives wrapped in volatile inhibitor-embedded films (MIL-PRF-3420H).

Desiccant Capsules: Humidity control during Sea Transport.

Cosmoline Application: Critical interfaces coated in temporary heavy-duty anticorrosive grease.

Double Worm Slew Drive Characteristics

Redundant Drive: Dual worms ensure continuous operation if one worm fails.

High Torque Density: 8,000-500,000 Nm output range.

Precision Backlash Control: ≤3 arc-min with preloaded designs.

Overload Capacity: 250% static torque rating.

Thermal Management: Integrated cooling fins or forced-air options.

Applications Demanding Corrosion Resistance

Offshore Wind: Jacket foundation access cranes, anode handling systems.

Marine & Shipbuilding: Deck cranes, hatch cover actuators, sonar arrays.

Coastal Solar Farms: Tracker drives in salt-spray zones.

Chemical Processing: Reactor lid manipulators, acid storage rotators.

Mining & Mineral Processing: Slurry mixer drives, stacker reclaimers.

Price Influencing Factors

Corrosion Protection Level: C5-M (ISO 12944) adds 20-35% cost vs. C3.

Material Upgrades: Aluminum bronze wheels (+25%), 316L fasteners (+15%), ceramic bearings (+40%).

Sealing: IP69K sealing system adds 18-22% vs. IP66.

Coatings: Zn-Ni + epoxy (+12%), full hot-dip galvanizing (+30%).

Precision: ≤3 arc-min backlash tolerance increases cost 20%.

Certifications: DNV-GL/ABS marine certification adds 15%.

Thermal Management: Forced-air cooling adds 8-12%.

Double Worm Slew Drive Supplier

LYRADRIVE engineers corrosion-optimized double worm slew drives featuring patented Zn-Ni electroplating and C95400 aluminum bronze gearing for 20+ year service in ISO 12944 C5-M environments. Our drives integrate triple FKM seal labyrinths and VCI cavity protection, validated through 1,000hr salt spray testing per ASTM B117. With 40% of units deployed offshore, LYRADRIVE provides corrosion audit reports and customized maintenance protocols.