Slewing Drives Powering Renewable Energy

What is Worm Gear Slew Drive

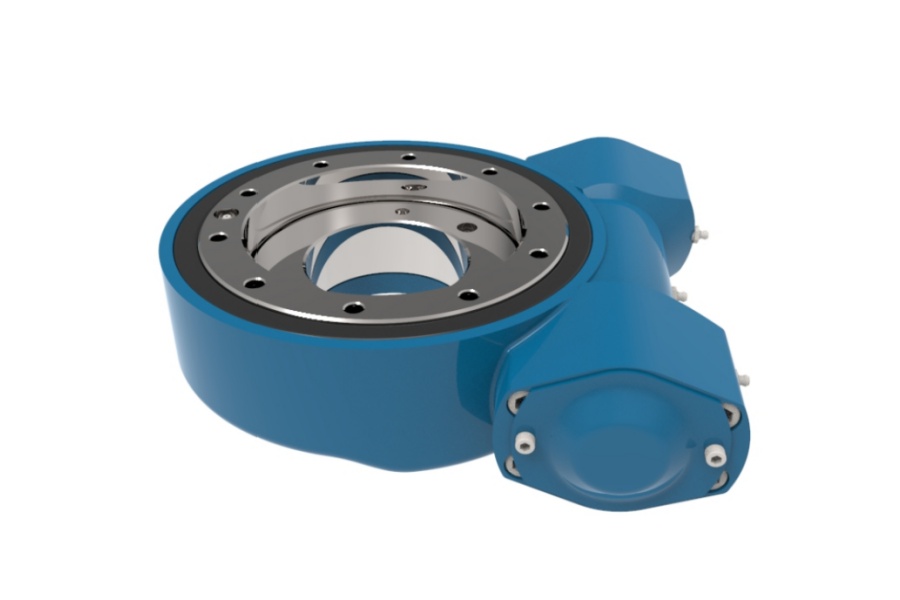

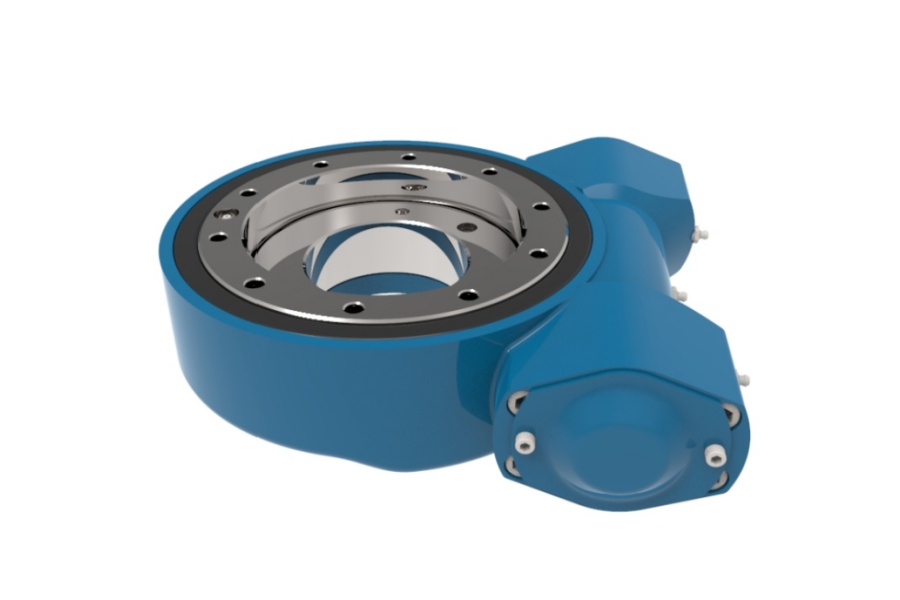

Worm Gear Slew Drive integrates a precision worm gear reducer with a slewing bearing into a compact unit. The input worm shaft engages with gear teeth on the bearing’s inner/outer ring, converting high-speed rotation into high-torque, low-speed output. Its defining feature is self-locking capability – the worm can drive the gear wheel, but reverse motion is mechanically inhibited. Designed for heavy-duty positioning with minimal maintenance.

Worm Gear Slew Drives in Renewable Energy

Solar Energy Applications:

Solar Tracker Azimuth & Elevation Axes:

Drive solar panels to follow the sun’s path with ±0.1° precision, increasing energy yield by 25-40%.

Self-locking eliminates brake systems during high winds (IEC 61400-2 compliant).

Concentrated Solar Power (CSP) Heliostats:

Position mirror arrays to focus sunlight onto receivers with millimeter accuracy.

Key Advantages for Solar:

Wind Resistance: Withstand 150km/h wind loads without auxiliary brakes.

IP66/IP68 Sealing: Protect internals from desert dust/sandstorm ingress.

Corrosion Resistance: Zinc-nickel plating withstands coastal salt spray (ISO 9227).

Backlash Control: <10 arc-min precision maintains optical alignment.

Wind Energy Applications:

Yaw Drive Augmentation:

Assist main yaw systems during low-wind alignment or emergency positioning.

Blade Pitch Backup Systems:

Provide failsafe adjustment during grid outages or main pitch system failure.

Service Crane Rotation:

Enable 360° positioning of maintenance cranes inside nacelles.

Key Advantages for Wind:

Overload Protection: 200% static torque capacity handles gust-induced shocks.

Maintenance Reduction: 10,000-hour regreasing intervals vs. 2,000h for hydraulic alternatives.

-40°C to +80°C Operation: Reliable performance in Arctic/offshore environments.

Emerging Renewable Applications:

Hydrokinetic Turbine Alignment: Adjust turbine angles to tidal/current flow directions.

Biomass Feeder Rotators: Precisely orient feedstock conveyors in biogas plants.

Worm Gear Slew Drive Characteristics

Self-Locking: Inherent braking (static holding ratio ≥1:50) eliminates external brakes.

High Torque Density: 5,000-200,000 Nm output torque in compact packages (Ø300-1500mm).

Impact Resistance: Robust construction handles wind/tidal shock loads.

Precision Positioning: Low backlash options (<5 arc-min) for optical alignment.

Sealed for Life: Triple-lip seals with FKM retain grease and exclude contaminants.

Corrosion Protection: Zinc-nickel plating or epoxy coatings (ISO 12944 C5-M).

Efficiency: 55-85% (dependent on ratio/lubrication), optimized for low-speed duty cycles.

Applications Beyond Renewables

Construction: Crane jib rotation, concrete mixer positioning.

Material Handling: Stacker-reclaimer slew, conveyor turntables.

Industrial Automation: Welding positioners, radar antenna rotation.

Agriculture: Irrigation pivot drives, grain bin sweep rotation.

Price Influencing Factors

Torque Rating: 20,000Nm+ drives cost 40% more than 5,000Nm equivalents.

Precision Level: <5 arc-min backlash adds 15-30% cost.

Sealing: IP68 rating increases cost 20% vs. IP54.

Material: Aluminum bronze worm wheels add 25% cost vs. phosphor bronze.

Gear Quality: Hardened/ground worms (HRC 58±2) cost 30% more than induction-hardened.

Certifications: IEC 61400/IEC 62109 compliance adds 10-15%.

Thermal Management: Integrated heat sinks for desert use increase cost 12%.

Mounting Kits: Custom flanges/adapters add 5-15%.

Worm Gear Slew Drive Supplier LYRADRIVE

LYRADRIVE engineers high-reliability slew drives specifically for renewable energy’s extreme demands. Our units feature precision-ground EN36C steel worms (HRC 60) mated with aluminum bronze wheels for 100,000+ hour service life. Patented triple-sealing systems (IP68) protect against sand/water ingress, while low-temperature greases ensure consistent torque at -40°C. With 70% of production dedicated to solar/wind projects, LYRADRIVE provides technical co-design support for tracker OEMs and EPCs.

Worm gear slew drives are indispensable for maximizing renewable energy output. Their self-locking precision enables solar trackers to maintain perfect alignment without power-intensive brakes, directly boosting ROI. In wind applications, they provide critical failsafe positioning during grid instability. While initial cost is influenced by torque, sealing, and material choices, LYRADRIVE’s optimized designs deliver 25% lower lifecycle costs through extended service intervals and reduced downtime. As renewables expand into harsher environments, robust slew drives will remain key to converting natural forces into reliable clean energy.