Single Row Ball versus Crossed Roller Slewing Bearing Structural Performance Analysis

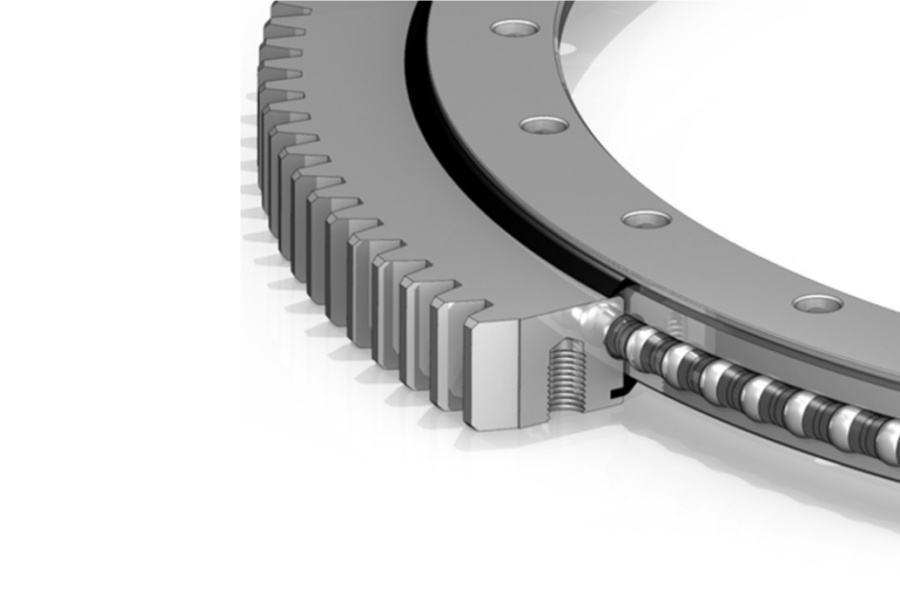

What is Single Row Slewing Ring Ball Bearings

Single Row Slewing Ring Ball Bearings feature a robust inner ring and outer ring with a single circular raceway containing precision balls separated by spacers or a cage. Characterized by four-point contact geometry between each ball and the hardened, curved (gothic arch) raceways, this design efficiently handles combined axial, radial, and tilting moment loads simultaneously within a compact cross-section.

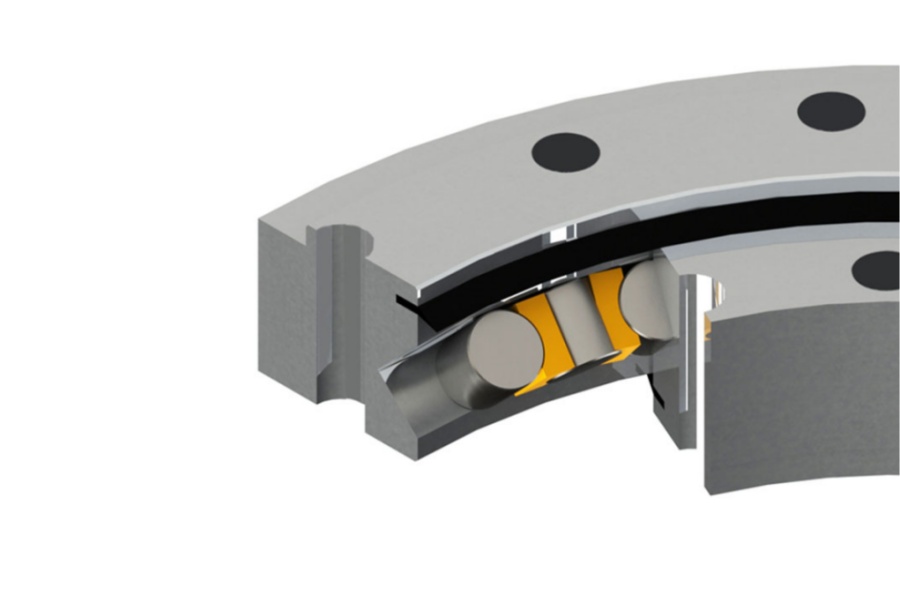

What is Crossed Roller Slewing Bearings

Crossed Roller Slewing Bearings consist of an inner ring, outer ring, and a single row of cylindrical or tapered rollers arranged alternately at 90-degree angles to each other within precision-ground, flat or slightly angled raceways. The rollers are typically guided by an integral cage. This configuration allows adjacent rollers to transmit loads in perpendicular directions.

Structural Performance Analysis: Single Row Ball vs. Crossed Roller

Single Row Ball Slewing Ring Performance:

Contact Mechanics:

Contact Type: Point contact at four theoretical points per ball (optimized force distribution).

Contact Position: Achieves positions close to theoretical load-bearing points under ideal conditions.

Stress Distribution: Hertzian point contact stresses align well with theoretical calculations.

Motion & Friction:

Rolling Element Motion: Pure rolling motion dominates.

Rotational Torque: Low resistance due to minimal sliding friction.

Manufacturing:

Structure: Two-ring design (inner and outer).

Processing: Raceways are complex double-curved (gothic arch) profiles requiring specialized grinding tools and processes. Material removal is less than crossed roller designs.

Structural Behavior:

Rigidity: High stiffness results in low elastic deformation under load. Less demanding on mounting surface flatness and rigidity.

Rolling Elements:

Cost & Logistics: Steel balls are relatively inexpensive and easier to source and grade match.

Dynamic Capacity:

Theoretical vs. Actual: Theoretical dynamic capacity is generally lower than crossed roller bearings of comparable size. However, it reliably achieves close to its theoretical capacity due to predictable stress distribution and pure rolling contact.

Crossed Roller Slewing Bearing Performance:

Contact Mechanics:

Contact Type: Line contact.

Contact Position: Designed for contact at the center of the roller/raceway. Prone to deviation due to cone angle errors and assembly clearances, leading to sub-optimal and potentially damaging edge loading.

Stress Distribution: Theoretical line contact stress calculations often overestimate performance; actual stress distribution is frequently non-uniform due to contact position deviations and manufacturing tolerances.

Motion & Friction:

Rolling Element Motion: Primarily rolling, but inherent sliding occurs at the roller ends against flange guides and potentially between rollers and raceways due to misalignment or load.

Rotational Torque: Significantly higher resistance than ball bearings (typically double), primarily due to friction at roller ends and roller/raceway sliding components.

Manufacturing:

Structure: Typically requires three rings (inner, outer, spacer ring) or complex integral flanges.

Processing: Raceways are simpler right-angled profiles, often manufacturable with standard turning/grinding equipment. Higher material usage and machining volume compared to ball bearings.

Structural Behavior:

Rigidity: Lower overall rigidity than comparable ball bearings, leading to higher elastic deformation under load. Demands high mounting surface flatness and structural rigidity.

Rolling Elements:

Cost & Logistics: Rollers are more expensive than balls. Achieving precise size matching across a full bearing complement is more challenging.

Dynamic Capacity:

Theoretical vs. Actual: Theoretical dynamic capacity based on line contact is high (often 50%+ higher than equivalent ball bearing). However, due to contact position deviations, non-uniform stress distribution, and roller end effects, the practically achievable dynamic capacity is frequently only about 1/3 of the theoretical value and can be lower than that of a well-designed single-row ball bearing of similar size.

Applications

Single Row Ball Slewing Ring Applications:

Construction Machinery: Excavator swing bearings, compact crane slewing.

Material Handling: Rotators, conveyors, moderate-duty turntables.

Renewable Energy: Solar tracker azimuth drives (small/medium).

Industrial Automation: Welding positioners, indexing tables.

Medical: Scanner bases requiring smooth motion.

Ideal for: Applications needing compact design, smooth low-torque rotation, good combined load capacity, and cost-effectiveness where extreme precision or maximum rigidity isn't paramount.

Crossed Roller Slewing Bearing Applications:

High-Precision Machinery: CNC rotary tables, robotic arm joints, coordinate measuring machines (CMM).

Machine Tools: Precision indexing heads, grinding machine spindles.

Semiconductor Manufacturing: Wafer handling robots, lithography stages.

Medical Imaging: CT/MRI gantry rotation requiring minimal deflection.

Optics & Defense: Radar pedestals, telescope mounts, laser targeting systems.

Ideal for: Applications demanding exceptional rigidity, minimal elastic deformation, high positional accuracy (low backlash variants), and high moment stiffness, often in moderate load ranges.

Price Influencing Factors

Single Row Ball Slewing Ring Price Factors:

Size & Load Rating: Diameter and capacity.

Material & Heat Treatment: Alloy steel grade, depth/quality of case hardening.

Raceway Grinding Precision: Complexity of gothic arch profile grinding.

Gear Teeth: Inclusion, module size, quality (AGMA/DIN), hardening.

Sealing: Seal type (lip count, material like FKM/NBR), IP rating.

Ball Quality: Precision grade (G10, G16), material.

Mounting Features: Bolt hole complexity, counterbores.

Quantity & Customization: Volume discounts; non-standard designs cost more.

Crossed Roller Slewing Bearing Price Factors:

Size & Load Rating: Diameter and nominal capacity.

Material & Heat Treatment: Alloy steel, precision of raceway hardening/grinding.

Roller Precision: Roller diameter consistency, straightness, surface finish.

Cage Complexity: Design and material (phenolic, brass, steel).

Flange Design: Integrated flanges vs. separate spacer rings.

Precision Level: Low backlash, high flatness/parallelism tolerances significantly increase cost.

Sealing: High-performance sealing is complex due to the open design.

Mounting Features: Precision mounting surfaces.

Quantity & Customization: Higher base cost than ball bearings; customization premiums apply.

Slewing Bearing Supplier LYRADRIVE

LYRADRIVE supplies high-performance Single Row Ball Slewing Rings and precision Crossed Roller Slewing Bearings engineered for diverse industrial demands. Our ball bearings leverage optimized gothic arch raceways for reliable combined load handling, while our crossed roller solutions prioritize rigidity and minimal deflection for precision applications. LYRADRIVE focuses on robust construction, precise manufacturing, and adherence to quality standards, providing technical expertise to ensure optimal bearing selection and integration.

Selecting between Single Row Ball Slewing Rings and Crossed Roller Slewing Bearings involves fundamental trade-offs. Ball bearings excel in compactness, smooth low-torque rotation, cost-effectiveness, and achieving reliable dynamic capacity close to theoretical values under combined loads. Crossed roller bearings offer superior rigidity and minimal elastic deformation for precision positioning, but at a higher cost, with significantly higher rotational torque, and often fail to realize their theoretical dynamic capacity potential due to contact instability and roller end effects. Engineers must prioritize application requirements: compactness and efficiency favor ball designs, while ultimate precision and stiffness justify crossed rollers despite their drawbacks. Partnering with experienced suppliers like LYRADRIVE ensures access to bearings optimized for their intended structural performance envelope.