Worm Gear Slew Drive Installation Requirements

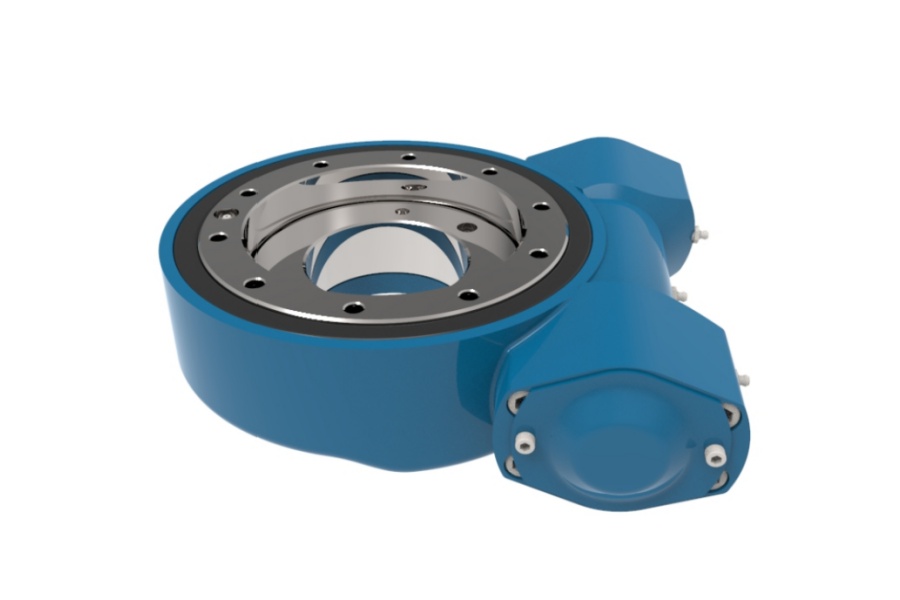

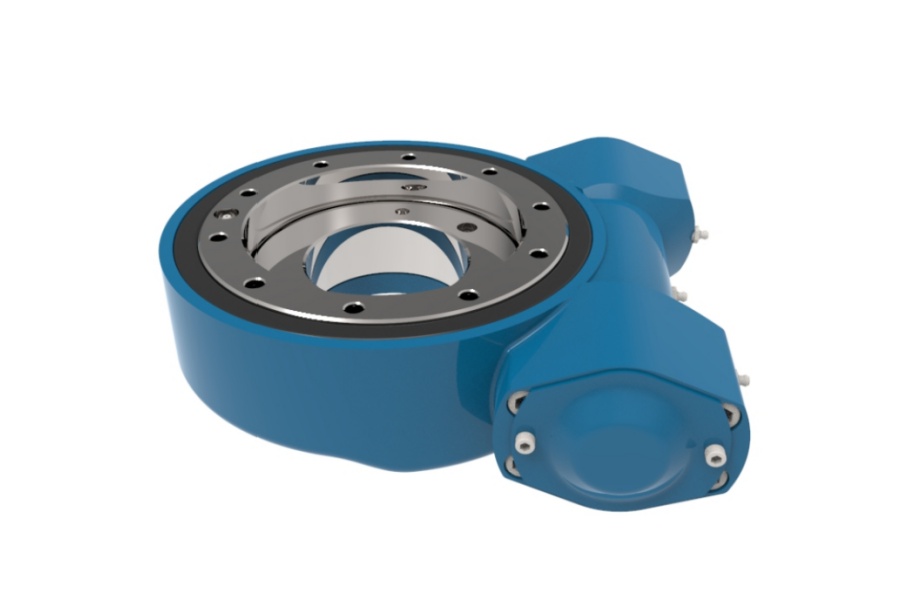

What is Worm Gear Slew Drive

Worm Gear Slew Drive is an integrated motion system combining a high-ratio worm gear reducer, precision slewing bearing, seals, and housing into a single compact unit. The worm shaft (input) engages with a gear wheel on the bearing’s outer/inner ring, converting input rotation into high-torque, low-speed output with inherent self-locking capability. Designed for applications requiring precise positioning under heavy loads with holding stability.

Worm Gear Slew Drive Installation Requirements

Proper installation is paramount for performance and lifespan. Follow these steps meticulously:

Pre-Installation Preparation

Inspect: Check the slew drive for shipping damage (dents, cracked seals, impact marks).

Clean Components:

Thoroughly clean the slew drive housing and mounting surfaces of the support structure using lint-free cloths.

Remove all contaminants: dirt, metal shavings, burrs, paint overspray, weld spatter, grease, or anti-corrosion oil.

Critical Cleaning: Use approved solvents (e.g., isopropyl alcohol, specialized degreasers). Avoid diesel, gasoline, benzene, or acetone near seals – they degrade rubber. Follow solvent safety protocols (ventilation, PPE).

Surface Preparation: Ensure mounting surfaces are flat (verify with straight edge), smooth (Ra ≤ 3.2 μm recommended), and free of protrusions. Lightly oil cleaned metal surfaces immediately to prevent rust.

Handling: Use designated lifting points. Remove transport locking bolts/plates before final positioning.

Bolt Selection & Verification

Grade: Use only high-tensile strength bolts (e.g., Grade 8.8, 10.9, or 12.9 per ISO 898-1). Never substitute with lower-grade hardware.

Fit: Bolts must fit snugly in holes without play.

Washers: Always use high-quality, hardened flat washers under bolt heads and nuts to distribute load and prevent surface galling. Disc spring washers may be specified for critical applications. Avoid damaged or low-quality spring washers.

Thread Engagement: Ensure full thread engagement length ≥ 1.5 times the bolt diameter. Trim bolts if excessive length causes interference.

Contact Stress: Calculate/verify contact pressure under bolt heads using washer size. Do not exceed the housing material’s allowable stress. Use larger washers if needed.

Threadlocker: Apply medium-strength threadlocking compound (e.g., Loctite 243) to bolt threads unless otherwise specified.

Mounting Procedure

Positioning: Carefully lower the slew drive onto the prepared mounting surface. Ensure no foreign objects are trapped.

Initial Bolt Insertion: Hand-tighten all bolts initially to align the drive.

Cross-Bolting Sequence:

Tighten bolts gradually in a star or cross pattern (diagonally opposite bolts) over multiple passes.

Pass 1: Torque all bolts to 30% of final specification.

Pass 2: Torque all bolts to 60% of final specification.

Pass 3: Torque all bolts to 100% of final specification.

Torque Application: Use a calibrated torque wrench. Apply torque smoothly and steadily. Re-check torque after 24-48 hours of operation if possible.

Alignment: Ensure the drive sits flush without rocking. Verify input shaft alignment with the driving motor (if pre-mounted).

Sealing Bolt Holes: If blind holes are used, ensure they are clean and dry. If through-holes exist on non-sealed faces, seal them completely with high-quality silicone or thread sealant before bolt insertion to prevent water/dust ingress. Do not apply sealant after bolting.

Marking: Paint-mark bolt heads and the mounting surface after final torquing to facilitate visual inspection for loosening.

Post-Installation Checks

Rotation: Manually rotate the output ring (if possible) to check for smoothness, binding, or unusual noise before connecting loads or powering the input.

Lubrication: Verify grease levels per manufacturer specs. Connect auto-lube systems if equipped.

Seal Inspection: Ensure seals are undamaged and seated correctly.

Worm Gear Slew Drive Characteristics

High Reduction Ratio: Achieves significant speed reduction/torque multiplication in a single stage.

Self-Locking: Inherent braking capability prevents back-driving under most loads (worm cannot be driven by the wheel).

Compact & Integrated: Combines bearing, gearing, and housing into one unit.

High Shock Load Resistance: Robust design handles impact loads well.

Precise Positioning: Low backlash variants available for accurate control.

Moderate Efficiency: Typically 50-90%, lower than spur/helical drives due to sliding friction.

Smooth & Quiet Operation: At lower speeds.

Worm Gear Slew Drive Applications

Solar Trackers: Azimuth and elevation rotation.

Material Handling: Conveyor turntables, rotators, stackers/reclaimers.

Construction: Crane jib rotation, concrete mixer positioning.

Wind Energy: Yaw brake adjustment, auxiliary drives.

Industrial Automation: Indexing tables, welding positioners.

Defense: Radar, antenna positioning.

Agriculture: Irrigation pivot drives.

Factors Influencing Worm Gear Slew Drive Price

Torque/Speed Rating: Higher output torque/lower speed drives cost more.

Size & Material: Larger housings/gears and premium alloys (bronze wheels) increase cost.

Precision Level: Low backlash or high-precision grinding adds expense.

Bearing Type: Integrated slewing bearing type (ball, roller) and size.

Sealing: IP67/IP69K sealing significantly increases cost.

Gear Quality: Hardening (induction, case), grinding, material (aluminum bronze vs. phosphor bronze).

Input Configuration: Flange options, shaft types, brake integration.

Lubrication System: Integrated auto-lube adds cost.

Customization: Non-standard mounting, special coatings, sensors.

Certifications: CE, ISO, DNV-GL certification costs.

Quantity: Lower unit cost with volume orders.

Worm Gear Slew Drive Supplier

LYRADRIVE engineers and manufactures high-reliability worm gear slew drives designed for demanding applications like solar tracking and heavy-duty positioning. Our drives feature precision-ground hardened gears, robust integrated bearings, and advanced sealing systems ensuring long service life with minimal maintenance. LYRADRIVE provides expert technical support to guide correct selection and installation, helping customers optimize system performance and longevity.