Light Load Slewing Bearing Noise Solutions

What is Light Load Slewing Bearing

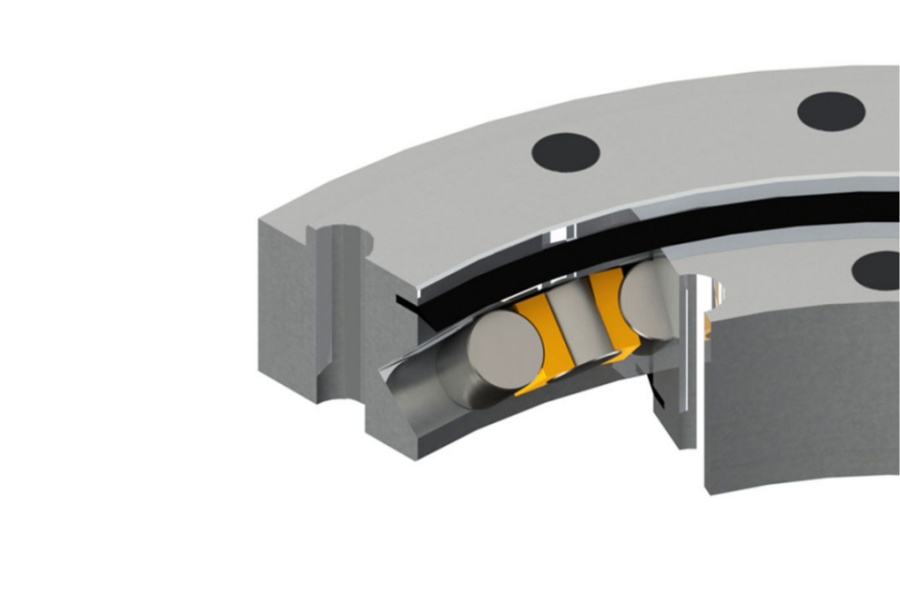

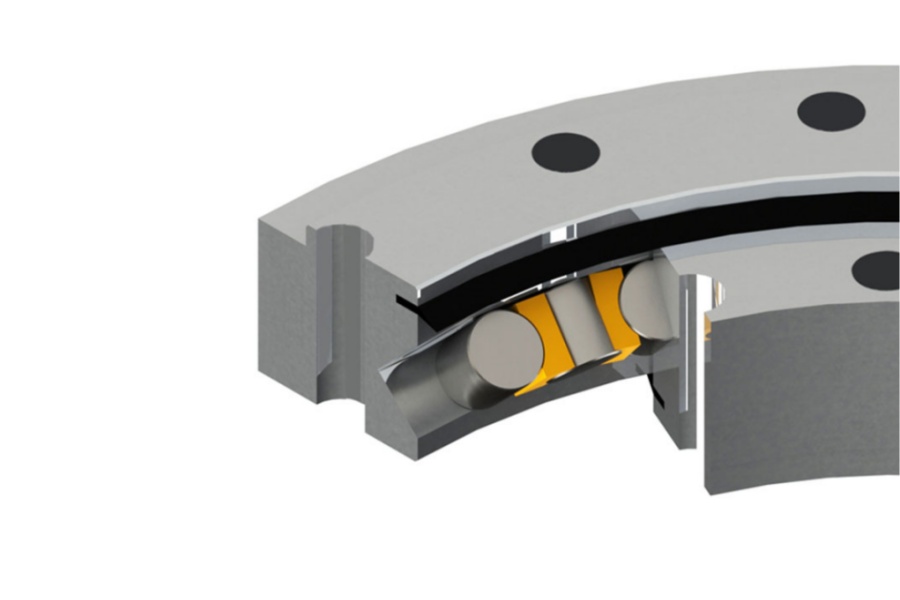

Light Load Slewing Bearing is a compact rotational bearing designed for moderate axial, radial, and moment loads. Characterized by single-row ball construction, optimized cross-sections, and simplified sealing, it delivers efficient rotation in applications where space, weight, and noise sensitivity are critical constraints.

Light Load Slewing Bearing Noise Solutions

Contamination-Induced Noise (Irregular Vibration & Rattling)

Cause: Dust/debris ingress damaging raceways or rolling elements.

Symptoms: Irregular scraping sounds, sporadic vibration amplitudes.

Solutions:

Precision Cleaning: Degrease bearing, shaft, and housing with ultrasonic cleaning (ASTM G131). Use non-residue solvents (e.g., isopropyl alcohol).

Seal Upgrade: Install triple-lip seals with PTFE-coated lips (friction torque <1 Nm).

Lubricant Filtration: Filter grease through 25μm mesh before injection.

Cage Material: Use glass fiber-reinforced PA66 cages instead of metallic spacers.

Component Damage Noise (Cyclic Clicking/Screeching)

Cause: Raceway brinelling, ball spalling, or corrosion pits.

Symptoms: Rhythmic clicking (1-5kHz) synchronized with rotation.

Solutions:

Installation Protocol: Use thermal mounting (ΔT≤80°C) with induction heaters. Never hammer bearings.

Corrosion Prevention: Apply VCI coating (MIL-PRF-81309) during storage.

Surface Treatment: Opt for REM-finished raceways (Ra≤0.1μm) to reduce stress concentration.

Load Verification: Confirm actual loads ≤30% of dynamic capacity (C/P ratio >3).

Lubrication-Related Noise (Low-Frequency Humming)

Cause: Incorrect grease viscosity, starvation, or degradation.

Symptoms: 200-800Hz constant drone, torque fluctuations >15%.

Solutions:

Grease Selection: Use ISO VG 32 lithium complex grease with Molybdenum disulfide (NLGI 2 grade).

Filling Ratio: Maintain 25-35% cavity volume (overfilling causes churning losses).

Relubrication Schedule: Automatic lubrication systems with 2,000-hour intervals.

Condition Monitoring: Implement grease dielectric constant testing (Δε>0.5 indicates degradation).

System Resonance Noise (Structural Buzzing)

Cause: Natural frequency match between bearing (50-150Hz) and supporting structure.

Symptoms: 80-120Hz harmonic buzz during acceleration/deceleration.

Solutions:

Preload Optimization: Apply 0.02-0.05mm negative clearance to shift natural frequency >15%.

Damping Treatments: Install constrained-layer dampers (CLD) on mounting surfaces.

Stiffness Enhancement: Increase support structure thickness by 20% or add ribbing.

Motor Alignment: Maintain <0.05mm shaft runout and <0.1° angular misalignment.

Light Load Slewing Bearing Characteristics

Low-Torque Design: 1-5 Nm rotational resistance at 1rpm

Noise-Optimized Geometry: Gothic arch raceways (R/R ratio 1.03-1.05)

Vibration Damping: NBR vibration-damping rings (attenuation >8dB)

Precision Grades: ABEC-3 equivalent tolerances

Sealed Construction: Triple-contact labyrinth seals

Applications of Light Load Slewing Bearing

Medical Imaging: CT scanner gantries (<45dB requirement)

Office Machinery: Robotic conference room displays

Semiconductor: Wafer inspection turntables

Food Processing: Packaging line rotators (IP69K)

Aerospace: Satellite antenna positioning

Price Influencing Factors

Precision Grade: ABEC-3 adds 25% vs commercial grade

Sealing: PTFE-coated lip seals cost 30% more than standard NBR

Raceway Finishing: Superfinishing (Ra≤0.05μm) increases cost 18%

Material: Vacuum-degassed 52100 steel adds 12%

Testing: NVH certification to ISO 13381 adds 15%

Light Load Slewing Bearing Supplier

LYRADRIVE specializes in sub-45dB silent slewing bearings featuring laser-etched micro-reservoirs in raceways for continuous lubricant film formation and proprietary NBR-PEEK composite seals reducing friction-induced harmonics by 70%. Our bearings undergo ANSI S12.50 acoustic testing, guaranteeing <42dB(A) at 10rpm under 30% load.