Worm Gear Slew Drive and Spur Gear Slew Drive Similarities and Differences

What is Worm Gear Slew Drive

A Worm Gear Slew Drive utilizes a worm screw to engage and rotate a worm wheel (often integrated into a slewing ring), offering high reduction ratios and inherent self-locking capabilities.

What is Spur Gear Slew Drive

A Spur Gear Slew Drive employs a standard pinion gear to mesh with and drive a spur gear slewing ring, characterized by higher efficiency and operational speeds.

What are the Similarities and Differences Between Worm Gear Slew Drive and Spur Gear Slew Drive?

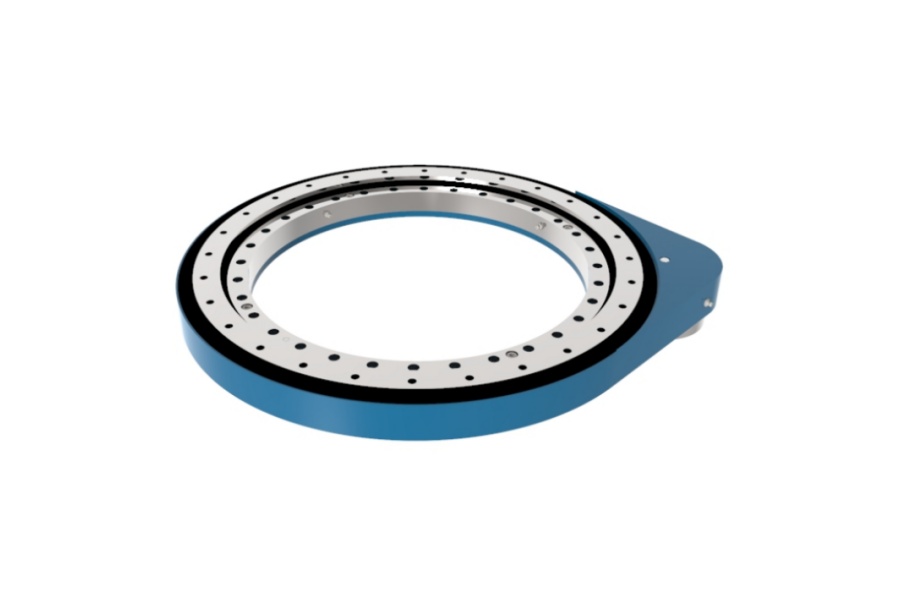

Both worm gear and spur gear slew drives share a common foundational purpose and several key design philosophies. They are both engineered as complete, sealed modules built around a central slewing bearing or ring. This core component is responsible for facilitating the rotational movement and supporting the combined loads from the superstructure. Common attachments include robust housings, mounting flanges, standard support bearings, and sealing systems. The shared advantages of this integrated approach include compact structural design, full sealing for protection against dust and water, simplified installation procedures, and significantly easier maintenance compared to assembling discrete components. Both types are capable of 360-degree continuous rotation, provide gear reduction, and are built to withstand demanding conditions.

Despite their similarities, the underlying drive mechanisms lead to profound differences in performance and application suitability. The first major difference lies in the drive principle itself. The worm gear slew drive operates on a worm-and-wheel system, where the rotary motion of the worm screw drives the wheel. The spur gear drive, however, functions through a pinion-and-spur-gear mechanism.

The second critical distinction is the reduction ratio. Worm gear drives inherently offer very high single-stage reduction ratios. In a typical configuration, the ratio is essentially equal to the number of teeth on the worm wheel. Spur gear drives provide a smaller reduction ratio, calculated by dividing the number of teeth on the slewing ring gear by the number of teeth on the pinion gear. Given that a pinion usually has far fewer teeth (e.g., around 15), the reduction ratio of a spur gear system is consequently much lower for similarly sized components.

A third, and often decisive, difference is the property of back-driving or self-locking. Worm gear slew drives possess a natural ability to resist back-driving due to the high friction angle in the worm-and-wheel interface. This means the load cannot reverse-drive the worm screw, effectively locking the system in place when power is removed. This is a crucial safety feature for applications like cranes or aerial work platforms where holding position is critical. Spur gear slew drives are not self-locking; the pinion can be driven backwards by the gear ring. While this seems like a disadvantage, it is beneficial in applications like forestry grapples or snow blowers where collisions are likely, as it allows the mechanism to yield, absorbing impact energy and protecting the drive system from damage.

The fourth difference is the operational speed limitation. The sliding action in a worm gear drive generates significant heat at higher speeds, limiting their maximum rotational speed, often to around 2.5 RPM or less to prevent overheating and failure. The rolling/engaging action of spur gear teeth is more efficient and generates less heat, allowing for much higher output speeds, typically in the range of 40 to 60 RPM.

The fifth key difference is transmission efficiency. The substantial sliding friction in a worm gear drive results in relatively low efficiency, often between 30% and 40%, meaning a significant portion of input power is lost as heat. Spur gear drives are highly efficient, with efficiencies reaching 90% to 95%, making them more energy-efficient and generating less waste heat for the same transmitted power.

Finally, the sixth difference is positional accuracy and backlash. Standard worm gear drives are generally affected by factors like wear and thermal expansion, making it challenging to achieve minimal backlash. High-precision versions might offer accuracy within 0.05 degrees. Spur gear drives can achieve higher precision, especially if the gears are ground. A one-meter diameter spur gear drive can potentially achieve positional accuracy within 0.01 degrees.

Characteristics of Worm Gear Slew Drive and Spur Gear Slew Drive

The characteristics of each drive type stem directly from their operational principles. The defining characteristic of a worm gear slew drive is its high reduction ratio and inherent self-locking capability. This makes it exceptionally reliable for static holding and precise, slow-speed positioning. However, it is characterized by lower mechanical efficiency, higher operational temperatures, limited maximum speed, and generally higher physical size and weight for a given torque output compared to spur gear systems. They are typically chosen for their safety and holding power rather than for speed or efficiency.

The spur gear slew drive is characterized by its high transmission efficiency and capability for higher rotational speeds. Its compact and often more lightweight design for a given power rating is a significant advantage. The inability to self-lock can be either a limitation or a designed feature depending on the application. It is characterized by smoother operation at speed, lower heat generation, and the potential for higher precision. It is the preferred choice for applications requiring rapid movement, high-duty cycles, and energy efficiency.

Applications of Worm Gear Slew Drive and Spur Gear Slew Drive

The application sectors for these two drives are largely defined by their characteristics. Worm gear slew drives are predominantly found in applications where safety, high torque at low speed, and holding position are paramount. They are extensively used in solar tracking systems to precisely position panels, in construction machinery like cranes and excavators for boom movement, in heavy-duty industrial turntables, and in material handling equipment where load security is critical. Their self-locking feature is indispensable in lifting applications and any situation where a loss of position could be hazardous.

Spur gear slew drives excel in applications that demand higher rotational speeds, superior efficiency, and frequent start-stop cycles. They are commonly employed in mobile equipment such as concrete pump trucks, telehandlers, and rotary excavators. They are also ideal for wind turbine yaw and pitch systems where efficiency impacts energy production, radar and antenna positioning requiring fast and accurate movement, and robotics. Their ability to allow controlled yielding under impact makes them suitable for rugged applications like log grapples and industrial sweepers.

What Factors Affect the Price of Worm Gear Slew Drive and Spur Gear Slew Drive?

The cost of both worm gear and spur gear slew drives is influenced by a common set of engineering and market factors. The primary determinant is the size, material quality, and manufacturing complexity of the internal slewing bearing. Larger bearings with higher load capacities and more sophisticated rolling elements (like crossed rollers) are more expensive. The precision grade required also significantly impacts cost; drives manufactured to tighter tolerances with lower backlash command a higher price.

The choice of materials for gears, housings, and seals affects both performance and price. High-strength alloy steels, specialized hardening processes, and corrosion-resistant coatings add cost. The drive's overall specifications, including maximum load moment, torque output, and required rotational speed, directly influence its size and complexity, thus its price. Additional features like integrated motors, high-performance brakes, special sealing for extreme environments, and custom mounting configurations will increase the unit cost. Furthermore, economic factors like order volume, brand reputation, and after-sales service and warranty terms also play a significant role in the final pricing structure.

Supplier

LYRADRIVE specializes in the design and production of integrated slew drives that simplify customer assembly and enhance machine performance. Their product range is developed to offer a compact footprint, ease of installation, and minimal maintenance. By providing a ready-to-install module, LYRADRIVE helps manufacturers reduce production time and costs while improving the overall reliability of their equipment. The company's expertise ensures that whether for a slow-moving, high-torque application needing a worm gear solution or a faster, more efficient spur gear system, clients receive a drive that is optimized for their specific application.