How to Select Backlash for Spur Gear Slew Drives

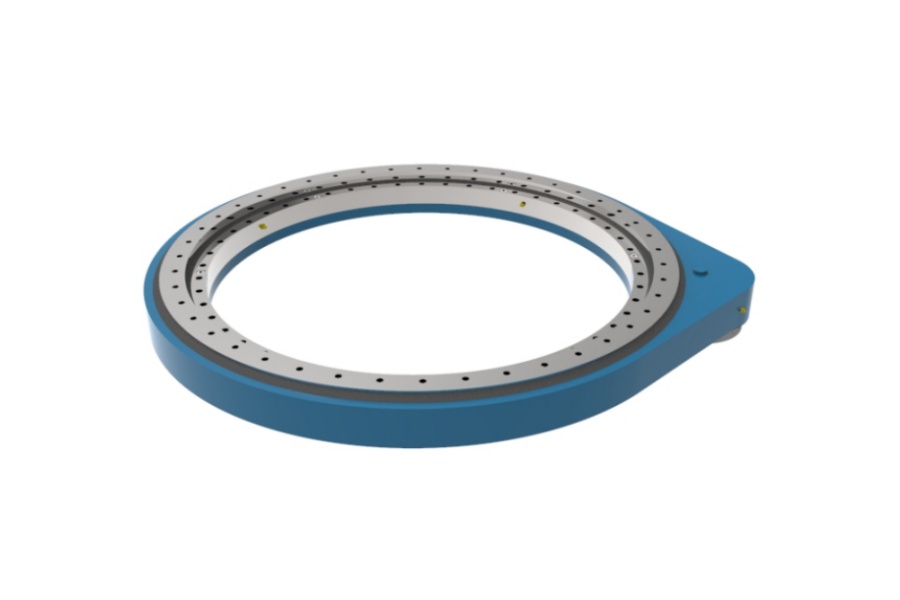

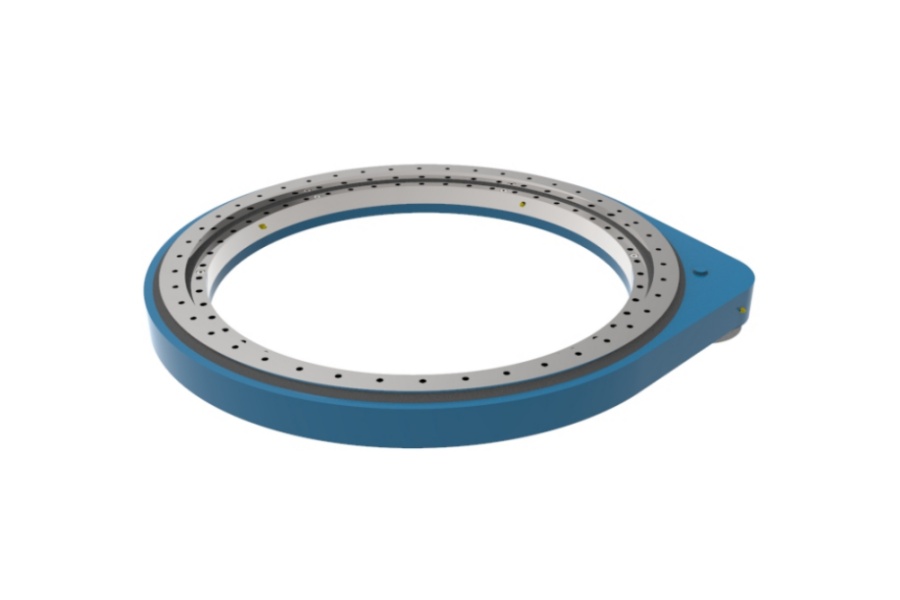

What is Spur Gear Slew Drive

Spur Gear Slew Drive is an integrated mechanical actuator system that combines a slewing bearing with a spur gear reduction and a compact housing, creating a self-contained unit designed to provide high-torque, controlled rotational movement for a wide range of heavy-duty and precision applications. Unlike simple bearings, a slew drive is a complete drive solution that incorporates a worm or pinion input shaft which engages with the internal spur gear teeth machined directly onto the slewing bearing's outer or inner ring. This configuration allows for a substantial gear reduction within a very compact form factor, significantly increasing output torque while reducing input speed, making it ideal for applications where powerful, slow, and precise rotation is required. The enclosed housing protects the internal gearing and bearing from environmental contaminants, contains lubrication, and provides a rigid structure for mounting directly onto machinery. The use of a spur gear design offers high efficiency and robust power transmission capabilities, distinguishing it from other drive types. By integrating the rotational support and the drive mechanism into a single, pre-assembled, and tested unit, spur gear slew drives simplify machine design, reduce assembly time, and enhance overall system reliability and performance, serving as a crucial component in industries ranging from solar energy and construction to robotics and industrial automation.

How to Select Backlash for Spur Gear Slew Drives

Selecting the correct backlash for a spur gear slew drive is a critical engineering decision that directly determines the system's performance, precision, longevity, and suitability for a specific application. Backlash, defined as the measurable amount of free movement or "play" between the meshing teeth of the drive pinion and the slew drive's internal gear, is not an indicator of defect but a designed-in characteristic that must be carefully chosen based on operational demands. It is primarily influenced by the internal clearance, of the integral slewing bearing itself. This selection process involves a fundamental trade-off between flexibility and precision, and can be categorized into three main types: large backlash, small backlash, and negative backlash.

Large backlash configurations are typically selected for applications where high precision is not a primary concern. This setting is ideal for equipment operating at very slow speeds, with minimal or no tilting moment loads, and where the installation foundation may not be perfectly machined or is prone to slight deflection. Examples include simple rotating platforms in agricultural equipment, basic material handling systems, and certain types of automated machinery that only require support and rotational motion without stringent accuracy requirements. A key advantage of large backlash is its ability to accommodate minor misalignments and imperfections in the mounting surface without inducing binding or excessive rotational resistance, ensuring smooth operation even under less-than-ideal installation conditions. However, this comes at the cost of reduced positional accuracy, potentially higher vibration levels, and increased gear wear over time if subjected to dynamic loads.

Small backlash setups are essential for applications demanding higher operational precision, faster rotational speeds, and where significant tilting moments are present. This reduced play between gear teeth ensures greater positional stability, minimizes unwanted movement or "drift" under load, and contributes to smoother operation at elevated speeds by reducing vibration and noise generation. This makes it the standard choice for a wide range of critical equipment, including solar tracking systems that must maintain precise panel alignment, construction machinery like excavators and cranes that handle unstable loads, and industrial positioning tables. Without a sufficiently small backlash, equipment performance would be compromised by inaccuracies, jerky motion, and accelerated component wear, leading to increased maintenance needs and potential downtime.

Negative backlash, or preload, represents the most precision-oriented configuration, where the gear mesh is intentionally tightened to eliminate any free movement. This advanced setting is reserved for the most demanding applications where exceptional positional accuracy, absolute rotational stiffness, and minimal transmission error are paramount. It is critical in high-precision machinery such as robotic welding and assembly cells, advanced medical imaging devices like CT scanners, military targeting systems, and high-accuracy satellite communication antennas. Negative backlash ensures virtually zero lost motion, maintains extreme accuracy over long periods, and enhances the system's rigidity against dynamic forces. However, this supreme performance requires a perfectly flat and rigid mounting foundation, generates higher operating temperatures due to constant friction, and demands superior manufacturing quality and lubrication, resulting in a higher initial cost and more complex maintenance requirements. Therefore, the choice of backlash is not about finding a universal best option, but about meticulously matching the drive's characteristics to the application's specific requirements for load, speed, precision, and environmental conditions.

Characteristics of Spur Gear Slew Drive

Spur Gear Slew Drives are defined by a distinct set of engineering characteristics that make them a preferred solution for applications requiring high torque and controlled rotation in a compact package. Their most prominent feature is their exceptionally high torque output relative to their size. This is achieved through a significant gear reduction ratio within the integrated system, where a small input rotation from a motor on the worm or pinion shaft is converted into a powerful, slow-velocity output torque at the drive's main rotation axis. This inherent capability allows them to move and position very heavy loads with precision, eliminating the need for complex external gearing systems.

Another critical characteristic is their compact and integrated design. Unlike traditional systems that require separate mounting of a bearing, a drive motor, and a gearbox, a slew drive combines all these functionalities into a single, sealed unit. This integration drastically simplifies the overall machine design, reduces the number of components, minimizes the required installation space, and streamlines the assembly process for OEM manufacturers. The design typically includes a robust, often cast housing that provides a rigid structure for mounting, protects the internal gears and bearing from contaminants, and serves as a reservoir for lubrication, enhancing service life and reliability.

Durability and ruggedness are engineered into their core. Manufactured from high-strength, hardened steels for both the worm/gearing and the integral slewing bearing, these drives are built to withstand severe operational conditions, including heavy shock loads, constant stop-start cycles, and exposure to harsh environments. The inclusion of high-quality sealing systems is paramount to this durability, effectively keeping out abrasive dust, moisture, and other contaminants that would otherwise lead to premature wear and failure. Furthermore, they offer significant design versatility. They can be customized with different gear ratios, various mounting configurations, alternative sealing solutions for extreme temperatures or corrosive environments, and a choice of backlash settings to precisely match the performance requirements of a vast array of applications, from heavy industrial machinery to delicate precision instruments.

Applications of Spur Gear Slew Drive

The application range of Spur Gear Slew Drives is extensive, spanning industries that require reliable, high-torque rotational actuation. They are a fundamental enabling technology in the renewable energy sector. In solar power generation, they are the core component of solar tracking systems, meticulously adjusting the angle of photovoltaic panels throughout the day to follow the sun's path, thereby maximizing energy capture efficiency. Similarly, they are used in the pitch and yaw control mechanisms of small to medium-sized wind turbines to optimize blade angle and nacelle orientation.

In construction and heavy equipment, their use is ubiquitous. They provide the rotational force for excavator booms, allowing for 360-degree movement, and are integral to the operation of mobile cranes, enabling the precise positioning of heavy loads. They are also found in concrete pump trucks, drill rigs, and compactors, where their ability to deliver high torque in a robust package is essential for reliable operation in demanding site conditions.

The industrial automation and robotics field heavily utilizes slew drives for precision motion control. They are employed in robotic welding arms, automated assembly lines, and material handling systems such as rotary index tables and palletizers, where their compact size and high positioning accuracy are critical. Their ability to handle significant moment loads makes them ideal for these tasks.

Beyond these core areas, their applications are diverse. They are used in defense for radar antenna and weapon system positioning, in medical technology for adjusting imaging equipment, in agriculture for controlling large irrigation systems, and in aerospace for ground support and testing equipment. This remarkable versatility, from moving massive solar arrays to positioning sensitive laboratory instruments, underscores the spur gear slew drive's role as a critical component in modern mechanical design.

Factors Influencing the Price of Spur Gear Slew Drive

The price of a Spur Gear Slew Drive is influenced by a confluence of engineering, material, and commercial factors that reflect its complexity and performance capabilities. The single most significant cost driver is often the size and load capacity of the integral slewing bearing. Larger diameters and higher load ratings require more raw material, more extensive machining, and more robust components, directly increasing the unit cost. The required precision tolerance grade, particularly the specified backlash level, also dramatically impacts price. Achieving and guaranteeing a small or negative backlash necessitates superior manufacturing equipment, more meticulous assembly processes, and 100% individual testing, all of which add substantial labor and overhead costs compared to a standard large-backlash unit.

The complexity of the design and the level of customization are another major determinant. A standard, catalog-specified drive will be far more economical than a fully custom-engineered solution. Customizations such as special sealing arrangements for extreme temperatures or submersion, unique flange or mounting hole patterns, specific shaft configurations on the input side, and special surface treatments or coatings (e.g., hard anodizing, nickel plating) for corrosion resistance all contribute to higher engineering and production expenses.

The choice of materials and internal components directly affects cost. While standard carbon chromium steel is common, applications requiring stainless steel for all wetted parts (e.g., in food and beverage or marine environments) will see a significant price increase. The quality and source of internal components like seals and the grade of lubricant used also factor into the final cost. Furthermore, the quantity ordered is a fundamental economic factor. Large volume production runs allow the manufacturer to amortize fixed costs (like custom tooling and setup) over many units, drastically reducing the price per drive. A one-off prototype or a small batch order will have a significantly higher unit cost. Finally, external supply chain factors like global steel prices, international logistics, and import/export tariffs can also cause fluctuations in the final price offered to the customer.

Supplier of Spur Gear Slew Drive

For engineers seeking reliable and technically proficient spur gear slew drive solutions, LYRADRIVE offers extensive expertise in the design and manufacture of these integrated systems. The company provides a range of standard and custom-designed drives, with a particular focus on guiding customers through critical selection parameters such as optimal backlash for their specific application requirements. LYRADRIVE's rigorous manufacturing and quality control processes ensure that its products deliver consistent performance, high torque output, and long-term durability for demanding applications in solar tracking, industrial automation, and heavy machinery.