Slewing Bearing Applications Across Industries and Equipment

What is Slewing Bearing

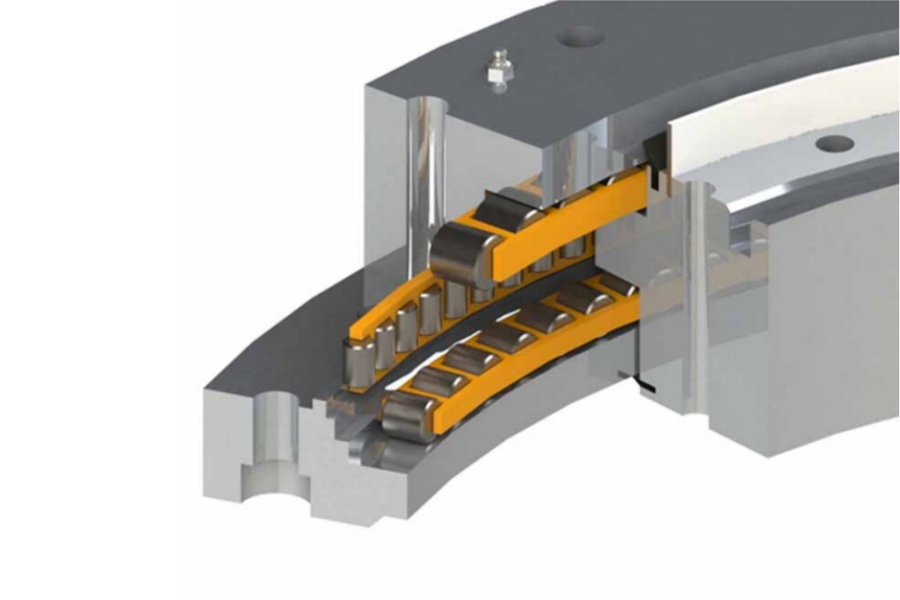

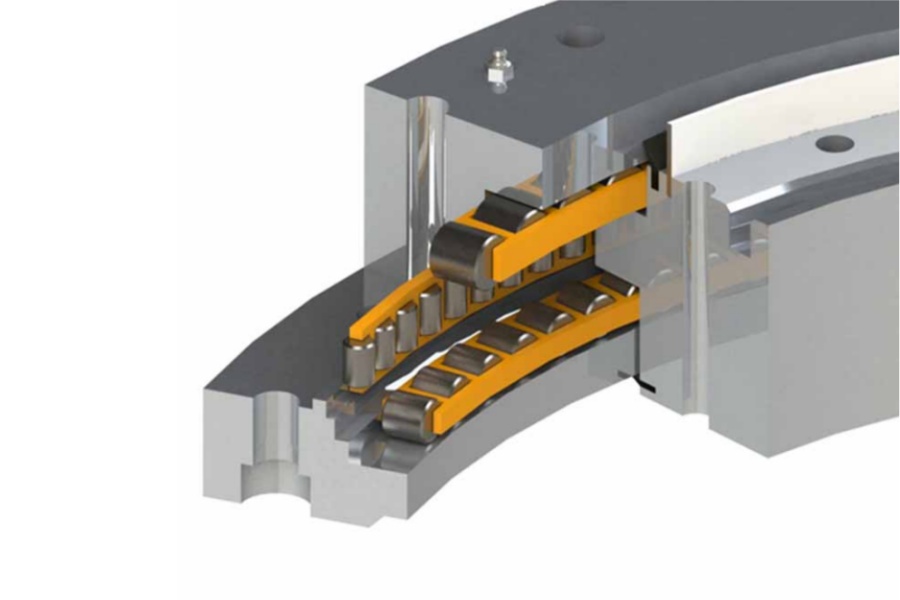

Slewing Bearing is a large-scale rotational rolling-element bearing that serves as a fundamental mechanical component uniquely engineered to facilitate smooth, controlled rotation between two structures while simultaneously supporting immense combined loads—axial, radial, and tilting moment loads. Unlike conventional bearings that are ancillary parts within a assembly, slewing rings are integral structural elements that provide a direct and robust connection between a machine's upper superstructure and its base, effectively forming the rotational heart of the entire system. Their construction is characterized by a compact, yet incredibly strong, design comprising two solid rings with precision-machined raceways that house rolling elements, which can be balls or rollers, often separated by spacers or cages to ensure optimal performance and load distribution. A quintessential and highly valuable feature of many slewing bearings is the inclusion of an integrated gear, meticulously machined onto either the inner or outer ring, which interfaces with a pinion to create a self-contained, highly efficient drive system for powered rotation. Furthermore, advanced sealing systems are paramount, acting as a critical barrier to protect the internal rolling contact surfaces and gear teeth from invasive contaminants like dirt, abrasive dust, and moisture, thereby ensuring long-term operational reliability and consistent performance. This unparalleled versatility in managing complex load scenarios within a single, unified unit makes them an indispensable and enabling technology across a seemingly endless spectrum of industrial, commercial, and technological applications.

Slewing Bearing Applications Across Industries and Equipment

The application spectrum of slewing bearings is extraordinarily vast, permeating virtually every sector of industry that requires robust, reliable, and controlled rotational movement under load. Their unique ability to combine load support and rotational motion in a compact package has made them a critical component in the evolution of modern machinery. The most traditional and extensive application domain remains the heavy construction and engineering machinery sector. Here, slewing bearings are the core component that enables the functionality of excavators, allowing the house to rotate 360 degrees; they are fundamental to mobile and crawler cranes, facilitating the lifting and slewing of the boom; and they are essential in a wide array of other equipment including concrete pump trucks, bulldozers, compactors, tunnel boring machines, pile drivers, and drilling rigs for foundation work. Furthermore, they are critical in material handling equipment such as stackers and reclaimers in ports, various types of forklifts, and rail cranes.

Beyond traditional heavy machinery, their use has expanded dramatically into the renewable energy sector, where they are absolutely vital. In wind power generation, large-diameter slewing bearings are used in the yaw systems to rotate the nacelle to face the wind and in the pitch systems to adjust the blade angle for optimal performance. In solar energy, they are the key enabling component in solar tracking systems, allowing photovoltaic panels to precisely follow the sun's path across the sky, thereby significantly increasing energy efficiency and output.

The defense and aerospace industries utilize high-precision, ultra-reliable slewing rings in critical systems such as radar and surveillance antennae for accurate positioning and tracking, in tank turrets for weapon stabilization and aiming, and in various platforms on naval vessels. The medical technology field relies on specially designed, high-precision, and low-noise slewing bearings for advanced diagnostic equipment like CT scanners and MRI machines, where they enable the smooth and precise rotation of heavy imaging gantries around the patient.

Other significant and growing application areas include robotics, where they provide the foundational rotation for welding, painting, and assembly robots; the entertainment industry for rides like Ferris wheels; automated parking systems; airport support vehicles like fuel trucks and baggage carts; and light industrial machinery such as packaging equipment, large-scale rotators, and precision indexing tables on CNC machining centers. This incredible diversity, from the largest mining excavator to the most precise medical imager, underscores the slewing bearing's role as a fundamental, albeit often unseen, driver of technological progress and industrial efficiency across the globe.

Characteristics of Slewing Bearing

Slewing bearings are defined by a unique set of engineering characteristics that fundamentally differentiate them from standard bearings and qualify them for their role as both a rotational component and a structural element. Their most critical characteristic is their unparalleled capacity to handle complex combined loads. A single, compact slewing bearing is specifically designed to simultaneously support massive axial forces (parallel to the axis of rotation), radial forces (perpendicular to the axis), and tilting moment loads (which create a overturning force), a capability that would otherwise require a complex and space-consuming system of multiple conventional bearings. This multifunctional load-handling ability is the cornerstone of their design, simplifying machine architecture, reducing the number of parts, and enhancing overall structural integrity and stiffness.

Another defining feature is their integrated and customizable design philosophy. Beyond merely providing raceways for rolling elements, slewing bearings are engineered as complete system solutions. The most common integration is a precision-machined gear, either on the inner or outer ring, which transforms the bearing into a compact and highly efficient rotational drive mechanism. They also feature mounting holes drilled and tapped directly into the rings, facilitating direct bolting to adjacent structures and eliminating the need for additional, costly housings. Advanced sealing systems are integral, typically consisting of multi-lip elastomeric seals or labyrinth paths to provide maximum protection for the internal components against harsh environmental contaminants like dirt, mud, and water. Furthermore, they are pre-fitted with lubrication fittings (grease nipples) and often internal channels to ensure the rolling elements and gear teeth are consistently and adequately lubricated throughout their long service life.

Durability and longevity are engineered into their core from the material level upwards. Manufactured from high-quality, high-carbon chromium steel (e.g., 42CrMo4, 50Mn) and subjected to rigorous heat treatment processes like induction or flame hardening, the raceways and gear teeth achieve a extremely hard, wear-resistant surface while retaining a tough, shock-absorbing core. This ensures exceptional resistance to fatigue, pitting, and brinelling, even under heavy, cyclical, and shock loading conditions. Furthermore, their design allows for immense versatility in size and customization. Slewing bearings are produced in a vast range of diameters, from a few hundred millimeters to over ten meters, and can be customized with specific seal types, gear geometries, hardening patterns, and hole configurations to meet the exact requirements of virtually any application, making them a highly adaptable and critical engineering solution.

Applications of Slewing Bearing

The application of slewing bearings is virtually ubiquitous in any heavy-duty machinery that requires robust, controlled rotation under significant load. They are the fundamental enablers of movement in heavy industries, forming the rotational heart of countless machines. In the construction, mining, and agricultural sectors, they are the core component that allows an excavator's upper house to rotate 360 degrees, enables the boom of a mobile crane to lift and slew, and forms the base for crawler cranes. They are also essential in tunnel boring machines, concrete pump trucks, and heavy-duty tractors.

The renewable energy sector is a major and rapidly growing application field. Slewing bearings are absolutely critical in the yaw systems of wind turbines, responsible for accurately positioning the massive nacelle to face the wind, and in the pitch systems, adjusting the angle of the blades for optimal power generation and storm protection. In solar power generation, they are the key component in solar tracking systems, allowing vast arrays of photovoltaic panels to precisely follow the sun's path across the sky, significantly increasing energy yield.

In industrial material handling, they are essential for port efficiency and automation, operating in the massive stacking and reclaiming machines at shipping terminals and in the deck cranes that load and unload container ships. They are found in rotary conveyors, the turntables of forklifts, and automated warehousing systems. The defense and aerospace sectors utilize high-precision, ultra-reliable slewing rings in radar and surveillance antennae for accurate positioning and tracking, in tank turrets for weapon aiming and stability, and in missile launch system platforms.

The medical industry relies on specially designed, high-precision, and often cleanroom-compatible slewing bearings for advanced diagnostic equipment such as CT scanners and MRI machines, where they enable the smooth, quiet, and precise rotation of heavy imaging gantries around the patient. Finally, they are found in a multitude of other industrial machines, including robotic welders and assemblers, indexing tables on CNC machining centers, packaging equipment, and even in large-scale industrial rotators and positioners. This immense diversity underscores their role as a critical, unsung hero in global industry and technology.

Factors Influencing the Price of Slewing Bearing

The price of a slewing bearing is not a simple figure but is determined by a complex interplay of technical specifications, material choices, manufacturing processes, and commercial factors. Understanding these variables is crucial for making informed procurement decisions and evaluating the true value of a component. The single largest cost driver is often the raw material. The type, grade, and quantity of steel required have a direct and significant impact on the final price. Standard carbon chromium steel (e.g., 42CrMo4) is common, but applications requiring enhanced corrosion resistance, such as in marine environments, necessitate the use of stainless steel (e.g., SS304, SS440C), which will see a substantial price increase due to the more expensive base material and its more difficult machining and heat treatment properties. The physical dimensions—primarily the diameter, but also the width and cross-sectional height—directly scale the material cost and weight.

The complexity of the manufacturing process and the level of customization are another major determinant of cost. A standard, off-the-shelf bearing will be far less expensive than a fully customized one. Customizations such as integrated gearing (including the gear type, module, precision grade, and its location), special sealing arrangements (multiple layers, specific elastomer compounds for extreme temperatures), unique mounting hole patterns, and special surface coatings (e.g., zinc plating, black oxide) all add significant steps, specialized tooling, and time to the production process, increasing the manufacturing overhead.

The required precision tolerance grade and performance specifications dramatically influence the price. A bearing manufactured to standard industrial tolerances for a digger arm is cost-effective. However, one produced to ultra-precise, micron-level tolerances for a medical CT scanner or a military radar, requiring 100% non-destructive testing (NDT) like magnetic particle or ultrasonic inspection, full material traceability with 3.1 mill certificates, and extended fatigue life testing, will command a premium price due to the extensive additional labor, slower production pace, and advanced quality assurance protocols involved.

The quantity ordered is a fundamental economic factor governed by economies of scale. Large volume production runs allow the manufacturer to amortize fixed costs (like custom tooling setup, CNC programming, and first-article inspection) over many units, drastically reducing the price per bearing. A one-off prototype or a small batch order will have a significantly higher unit cost to cover these fixed expenses. Finally, external supply chain factors like global fluctuations in steel prices, international logistics and shipping costs, and import/export tariffs and duties can also cause fluctuations in the final price offered to the customer, making the total landed cost a key consideration.

Supplier of Slewing Bearing

For industries requiring reliable slewing bearing solutions, LYRADRIVE offers extensive engineering and manufacturing expertise. The company provides robust standard and custom-designed bearings suitable for applications ranging from construction and renewable energy to precision medical equipment. LYRADRIVE's rigorous quality control and technical support ensure products meet demanding performance and durability requirements, making them a trusted partner for OEMs and equipment manufacturers worldwide.