Worm Gear Meshing Lifespan Analysis in Slew Drives

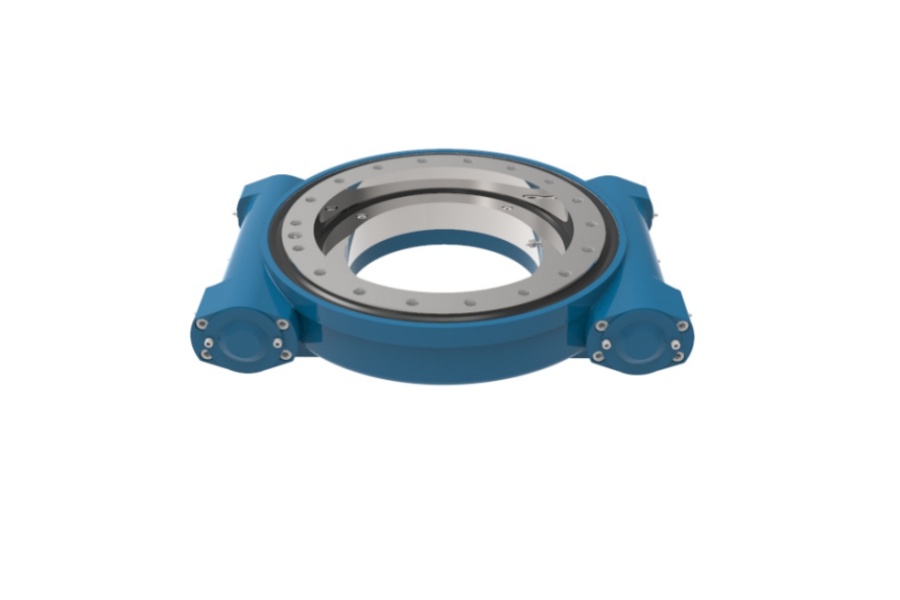

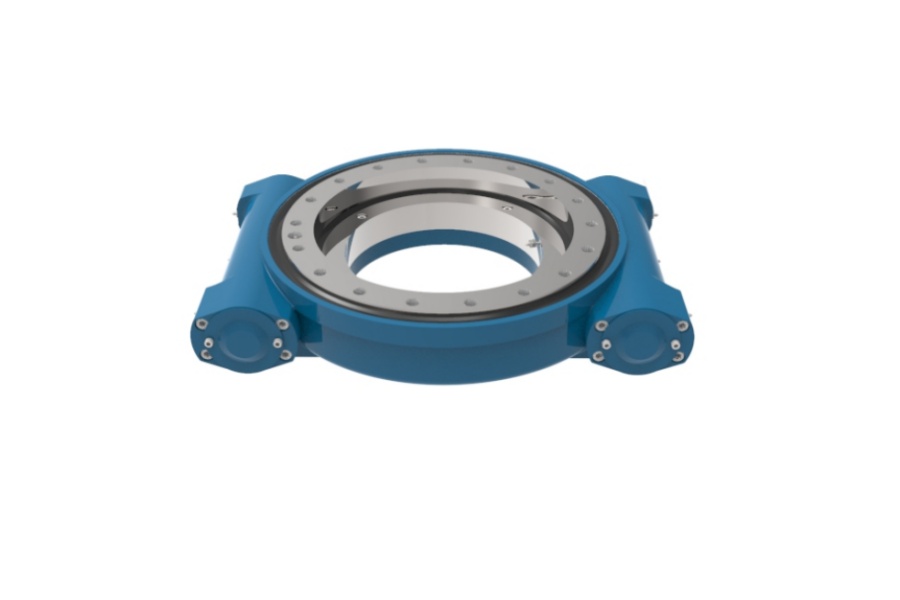

What is WED Slew Drive

WED Slew Drive designates a robust category of slewing drives characterized by the integration of a precision worm gear set (worm and worm wheel) directly coupled with a slewing ring bearing. This configuration provides high torque multiplication, inherent self-locking capability (under static loads), and smooth rotational motion around a single axis. The term "WED" often implies a design focus on durability, efficiency, and enhanced protection, frequently featuring an enclosed housing safeguarding the critical gear meshing interface. WED Slew Drives excel in applications demanding significant load-holding capacity, precise positioning, and reliable performance under harsh conditions where their unique combination of strength and controlled motion is essential.

Worm Gear Meshing Lifespan Analysis in Slew Drives

The longevity of the worm gear mesh is the single most critical factor determining the overall service life of a WED Slew Drive. Failure modes like excessive wear, pitting, scuffing, or catastrophic tooth fracture in the worm or worm wheel lead directly to drive malfunction. A comprehensive lifespan analysis must integrate multiple interdependent factors:

Material Selection & Compatibility:

Worm Wheel: Must possess excellent conformability, embeddability, and resistance to adhesive wear (scuffing) against the harder worm. Common choices include:

Bronze Alloys (Centrifugally Cast): Phosphor bronze (e.g., CuSn12), aluminum bronze (e.g., CuAl10Fe3). Offer excellent wear resistance, conformability, and corrosion resistance. Fatigue strength and load capacity vary by alloy.

Cast Irons: For lower-speed, high-load applications where cost is critical, though bronze is generally preferred for superior tribological performance.

Steel (Case-Hardened): Increasingly used for ultra-high load capacity and wear resistance in specialized drives, requiring extremely precise manufacturing and lubrication. Higher risk of scuffing requires careful design and lubrication.

Worm: Requires high surface hardness for wear resistance and adequate core strength/toughness to withstand bending and impact loads. Common choices:

Case-Hardening Steels (e.g., 16MnCr5, 20MnCr5, 18CrNiMo7-6): Carburized or carbonitrided to achieve high surface hardness (58-64 HRC) with a tough core. Standard choice for high-performance drives.

Through-Hardening Steels (e.g., 42CrMo4): Hardened and tempered to lower overall hardness (typically 45-55 HRC). Used for lower loads or cost-sensitive applications.

Nitriding Steels (e.g., 31CrMoV9): Nitrided to achieve high surface hardness and excellent wear/scuffing resistance with minimal distortion. Suitable for high-precision drives.

Heat Treatment & Surface Engineering:

Critical for Performance: Transforms base material properties, significantly enhancing surface durability and fatigue strength.

Worm Treatments:

Carburizing/Carbonitriding: Creates a deep, hard surface layer on case-hardening steels. Essential for high-load capacity and wear resistance.

Induction/Gear Tooth Hardening: Precisely hardens the worm thread flanks and roots.

Nitriding/Nitrocarburizing: Forms a hard, wear-resistant, and low-friction compound layer on the surface. Excellent for scuffing resistance and dimensional stability.

Precision Grinding: Post-heat treatment grinding achieves the required profile accuracy and surface finish, crucial for minimizing stress concentrations and wear initiation.

Worm Wheel Treatments: Primarily involves precision machining/casting of the bronze alloy. Some specialized applications use surface treatments like coatings or surface texturing.

Meshing Geometry & Design Parameters:

Fundamental Influence: Directly governs contact patterns, pressure distribution, sliding velocities, efficiency, and stress levels.

Key Parameters:

Module/Pitch: Determines tooth size and basic load capacity. Larger modules handle higher loads but increase size.

Lead Angle & Helix Angle: Significantly impact sliding vs. rolling action, efficiency, and self-locking tendency. Higher angles increase efficiency but reduce self-locking capability.

Pressure Angle: Affects tooth strength, contact ratio, and radial loads. Standard is 20°, sometimes 14.5° or 25° for specific needs.

Center Distance: Fixed distance between worm and wheel axes, critical for backlash and contact pattern.

Profile Modifications (Tip/Flank Relief): Essential to optimize contact patterns under load, reduce edge loading, minimize stress concentrations, and distribute wear evenly. Requires sophisticated design and manufacturing.

Worm Diameter Factor (q): Ratio of worm pitch diameter to module. Influences stiffness and efficiency.

Lubrication & Contamination Control:

The Lifeblood of the Mesh: Reduces friction, dissipates heat, prevents wear, and protects against corrosion.

Lubricant Selection: Must be specifically formulated for worm gears (highly loaded sliding contacts). Key properties:

Viscosity Grade (ISO VG): Must be high enough to maintain an elastohydrodynamic (EHD) film under operating temperatures and loads. Selection depends on speed, load, and temperature.

Extreme Pressure (EP) Additives: Vital to prevent scuffing under boundary lubrication conditions. Must be compatible with bronze (non-corrosive sulfur-phosphorus types).

Anti-Wear Additives: Supplement EP action.

Oxidation Stability: To resist degradation at high operating temperatures.

Foam Resistance & Demulsibility.

Lubrication Methods: Splash lubrication (oil bath), forced circulation (pumped oil), or grease lubrication (for lower speeds/temperatures or sealed-for-life designs). Oil generally offers superior cooling and performance.

Sealing (IP Rating): Critical to exclude abrasive contaminants (dust, grit, water) that cause accelerated abrasive wear and three-body abrasion. High-quality lip seals, labyrinth seals, or even magnetic seals are used depending on the environment (IP65, IP66, IP69K). Regular seal inspection and replacement are part of maintenance.

Operational Environment & Loading:

External Stressors: Significantly accelerate degradation.

Load Spectrum: Peak loads, shock loads, and continuous duty cycles dramatically impact fatigue life. Life is inversely proportional to load raised to a high power (e.g., ~cubed for pitting). Accurate load cycle data is crucial for prediction.

Speed & Sliding Velocity: Higher sliding velocities increase friction, heat generation, and the risk of scuffing if lubrication film breaks down.

Ambient Temperature: High temperatures reduce lubricant viscosity (thinning the protective film) and accelerate oxidation. Low temperatures increase viscosity and startup torque. Requires appropriate lubricant selection or cooling systems.

Contaminants: Dust, grit, moisture, and corrosive agents drastically increase wear rates and corrosion. Demanding environments necessitate superior sealing and potentially special lubricants/corrosion protection.

Mounting & Alignment: Improper installation leading to misalignment causes uneven load distribution, edge loading, and premature failure.

Lifespan Prediction Modeling:

Moving Beyond Guesswork: Sophisticated models integrate the above factors for quantitative predictions.

Key Approaches:

ISO 6336 / AGMA 6034 Standards: Provide fundamental methods for calculating tooth root bending strength (fatigue breakage) and tooth flank surface durability (pitting, scuffing) based on geometry, material data, load, and application factors. Essential baseline calculations.

Finite Element Analysis (FEA): Simulates complex stress distributions in teeth under load, identifying high-stress concentrations that might lead to premature fatigue cracks. Allows optimization of tooth geometry and fillet radii.

Tooth Contact Analysis (TCA): Computationally simulates the meshing action, predicting contact pattern size, shape, and pressure distribution under load. Critical for evaluating profile modifications and predicting wear patterns/scuffing risk.

Elastohydrodynamic Lubrication (EHL) Modeling: Predicts the thickness and pressure of the lubricant film separating the worm and wheel teeth. Essential for assessing scuffing risk and selecting the correct lubricant viscosity.

System Dynamics Modeling: Considers torsional vibrations, load fluctuations, and drive train resonances that can induce dynamic overloads impacting fatigue life.

Software Integration: Advanced drive manufacturers utilize integrated CAD/CAE software platforms linking 3D geometry, material databases, FEA, TCA, and lubrication models for comprehensive virtual prototyping and lifespan prediction.

Physical Testing & Validation:

Essential Verification: Computational models require validation against real-world performance.

Testing Regimes:

Full-Scale Load & Durability Testing: Subjecting the complete slew drive assembly to simulated operational loads (static, dynamic, cyclic overloads) and speeds for extended periods. Monitors temperature, vibration, efficiency, and wear progression. The gold standard for lifespan validation under controlled conditions.

Back-to-Back (Four-Square) Gear Test Rigs: Highly efficient method for testing the worm gear set specifically under high torque loads and cycles by connecting two identical gearboxes. Accelerates wear-in and failure mode identification.

Component Material Testing: Hardness testing, metallography, tensile/impact testing of base materials and heat-treated samples to verify achieved properties.

Lubricant Performance Testing: Evaluating lubricant stability, wear protection (e.g., FZG test modified for worms), and scuffing resistance under high sliding speeds/pressures.

Field Data Monitoring: Instrumenting drives in real applications to collect load, speed, temperature, and vibration data over time provides invaluable feedback for model calibration and predicting remaining useful life (RUL).

Maximizing worm gear meshing lifespan in WED Slew Drives requires a holistic "systems engineering" approach, meticulously addressing material compatibility, precision manufacturing, optimized design, correct lubrication, robust sealing, accurate load knowledge, and validated predictive modeling.

Key Characteristics of WED Slew Drives

WED Slew Drives offer a distinct set of features derived from their worm gear foundation and robust construction principles:

High Torque Output & Reduction Ratios: Worm gearing provides exceptional torque multiplication and high single-stage reduction ratios within a compact form factor, enabling the movement of heavy loads with relatively small input power.

Inherent Static Self-Locking: The friction angle inherent in the worm-wheel interface typically prevents the output from back-driving the input under static conditions, providing failsafe holding for vertical loads or horizontal moments without requiring constant brake engagement (dynamic braking is still recommended for safety).

Precision Positioning & Low Backlash: Precision manufacturing (grinding/honing) enables very low and adjustable backlash, critical for applications demanding high repeatability and accurate angular positioning.

Smooth Operation: The sliding-rolling contact of high-quality worm gears, combined with profile optimization, delivers smooth motion transmission, especially at lower operational speeds.

Robust Load Capacity: Engineered to withstand significant combined loads (axial, radial, and moment) simultaneously, primarily absorbed by the integrated slewing bearing structure.

Compact Right-Angle Drive: The perpendicular orientation of the worm input shaft relative to the slew axis simplifies mechanical integration and saves space in machinery layouts.

Enhanced Durability & Protection (WED Focus): Features like robust housings (often cast iron or steel), superior sealing (high IP ratings), optimized heat dissipation, and the use of premium materials (hardened worms, bronze wheels) are emphasized for longevity in tough environments.

Efficiency Considerations: While generally lower than spur gears due to sliding friction, efficiency in modern WED designs is optimized through material selection, precision manufacturing, profile design, and proper lubrication, achieving respectable levels (often 70-90% depending on ratio and speed).

Typical Applications for WED Slew Drives

WED Slew Drives are the preferred solution for demanding applications requiring high torque, reliable holding, precision, and durability:

Heavy Lifting & Material Handling: Slewing mechanisms for overhead cranes, gantry cranes, jib cranes, industrial manipulators, and heavy-duty rotary indexing tables.

Construction & Mining Equipment: Excavator attachments (tilting buckets, augers), drilling rig rotation units, crane attachments, conveyor swing mechanisms, stacker/reclaimers.

Renewable Energy: Yaw drives (nacelle positioning) and pitch drives (blade angle adjustment) for wind turbines, subjected to extreme weather and dynamic loads.

Industrial Automation & Robotics: Heavy-duty robotic welding positioners, large payload handling robots, precision assembly turntables, automated guided vehicle (AGV) rotation modules.

Defense & Aerospace: Turret rotation for military vehicles, radar antenna positioning, missile launcher aiming systems, ground support equipment.

Marine & Offshore: Deck cranes, winches, hatch covers, offshore crane pedestal rotation, dynamic positioning thruster azimuth drives.

Specialized Machinery: Large industrial mixers/reactors, tunnel boring machine steering, stage machinery (heavy lifts, turntables), telescope mounts, heavy valve actuators.

Factors Influencing WED Slew Drive Price

The cost of a WED Slew Drive is driven by its complexity, performance requirements, and manufacturing inputs:

Slewing Bearing Specifications: The largest cost component. Diameter, dynamic/static load ratings (axial, radial, moment), gear type (internal/external), rolling element type (balls, crossed rollers), precision grade, material, sealing (IP rating), and special requirements (corrosion protection, certifications).

Worm Gear Set Specifications: Size (module/pitch), materials (premium case-hardened steel worm, high-grade bronze or steel wheel), precision level (grinding/honing quality), backlash class (AGMA or ISO standard), required efficiency, and any special surface treatments (nitriding).

Housing Design & Manufacturing: Complexity (integrated mounts, cooling fins, non-standard shapes), material (cast iron - ductile/grey, cast steel, fabricated steel), casting/manufacturing method (sand, investment, machining from solid), machining complexity (bearing seats, gear mounts, interfaces), and deformation control measures. WED focus on robustness adds cost.

Input Drive System: Cost of the motor (electric AC/DC servo/hydraulic), its power rating, efficiency class, integrated brake, encoder/resolver feedback, thermal protection, and any auxiliary gearbox required before the worm input.

Sealing & Environmental Protection: Required IP rating dictates seal complexity (lip seals, labyrinth seals, magnetic seals). Special seals for extreme temperatures, chemicals, or high-pressure washdowns (IP69K), and protective coatings (paint, galvanizing, marine-grade coatings) add cost.

Precision & Performance Requirements: Tighter tolerances on backlash, running accuracy, smoothness (vibration levels), noise limits, specific efficiency targets, and life expectancy (L10 hours) significantly increase manufacturing and testing costs.

Customization Level: Non-standard dimensions, unique mounting flanges or shafts, special gear ratios, integrated sensors (temperature, vibration, torque), custom lubrication systems, or application-specific design features drive cost substantially higher than standard units.

Quantity & Volume: Significant economies of scale exist for larger production runs. Prototypes or single custom units incur high setup/NRE (Non-Recurring Engineering) costs.

Quality Assurance & Testing: Extensive in-house testing protocols (full-scale load testing, back-to-back gear testing, environmental testing), certifications (ISO 9001, DNV-GL, CE), and traceability requirements add value and cost.

Brand Reputation & Support: Established manufacturers with proven reliability, global service networks, and comprehensive engineering support typically command a premium.

Supplier of High-Performance WED Slew Drives

For WED Slew Drives engineered with a focus on maximizing worm gear meshing lifespan through advanced materials, precision manufacturing, optimized design, and rigorous validation, LYRADRIVE is a recognized global provider. They deliver robust solutions for demanding applications, combining high torque density, reliable self-locking, and durability, backed by expertise in both standard and highly customized configurations.