Slew Drive Housing Casting Deformation Control

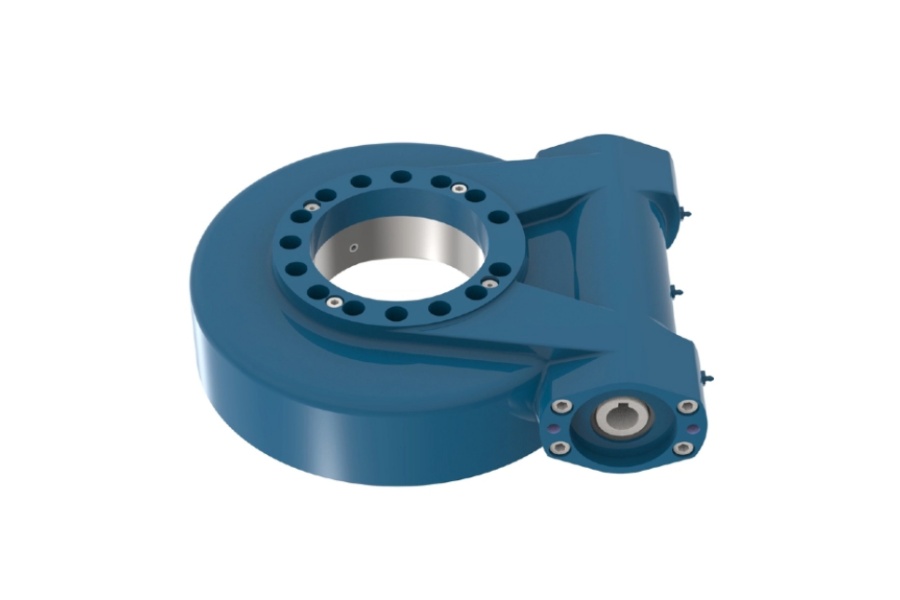

What is SE Slew Drive

SE Slew Drive represents a high-performance class of slewing drives utilizing a precision worm gear mechanism to achieve high reduction ratios and torque output within a compact envelope. In an SE Slew Drive, a hardened and ground worm screw engages with a worm wheel gear typically integrated into the slewing ring bearing's inner or outer race. This configuration offers exceptional mechanical advantage, inherent self-locking capability (preventing back-driving under static loads), and superior positioning accuracy due to minimized backlash achievable through precise manufacturing. SE Slew Drives are engineered for demanding applications requiring high torque, precise motion control, and reliable holding power, distinguishing them from spur gear variants by their ability to handle heavier loads and provide smoother operation at lower speeds.

Slew Drive Housing Casting Deformation Control

Designing and manufacturing the housing for SE Slew Drives, especially for non-standard configurations where the housing is integrated with a machine base or features complex external mounting geometries, presents significant challenges in controlling deformation during casting. Sand casting, the predominant method for these often large, intricate, and non-standard housings, is inherently susceptible to thermal stresses causing warping, distortion, and dimensional inaccuracies. Uncontrolled deformation compromises the critical alignment of the slewing bearing seat, worm gear mounting points, and motor interface, leading to premature bearing failure, uneven gear wear, excessive noise, vibration, and reduced efficiency. Implementing robust deformation control strategies is paramount:

Optimized Mold Design:

Predictive Compensation: Mold design must proactively incorporate allowances for the specific alloy's solidification shrinkage and predicted thermal deformation patterns based on simulation (e.g., Finite Element Analysis - FEA) and historical data. This involves strategic oversizing in areas prone to shrinkage and pre-distorting the mold cavity inversely to the expected warpage direction.

Rigid Pattern & Core Boxes: Utilizing high-strength, stable materials and precise construction for patterns and core boxes minimizes inherent variability introduced during mold creation.

Strategic Gating & Risering: Optimized placement and sizing of gating systems ensure smooth, controlled metal flow minimizing turbulence and heat concentration. Adequately sized risers placed strategically promote directional solidification towards the riser, reducing shrinkage porosity and associated stresses that contribute to distortion.

Strict Process Parameter Control:

Temperature Management: Precise control over molten metal pouring temperature is crucial. Excessive superheat increases thermal gradients and shrinkage stresses, while too low a temperature risks misruns and cold shuts. Maintaining consistent mold (sand) temperature minimizes uneven cooling rates.

Controlled Solidification & Cooling: Manipulating cooling rates through strategically placed chills (to accelerate cooling in thick sections) or insulating materials/sleeves (to slow cooling in thin sections or critical areas) promotes more uniform solidification, reducing internal stresses and distortion. Controlled cooling in the mold before shakeout is essential.

Sand Properties & Compaction: Consistent sand composition (binders, additives, moisture content) and uniform, high-density compaction throughout the mold cavity ensure consistent heat transfer rates and structural support, preventing mold wall movement or collapse during pouring that leads to dimensional errors.

Strategic Structural Design & Support:

Optimal Wall Thickness & Uniformity: Designing walls with consistent, adequate thickness avoids drastic changes in section size that cause uneven cooling and stress concentration. Ribs and fillets should be used to reinforce thin sections or transitions smoothly, not create new thick spots. Core designs must consider even metal distribution around them.

Integrated Support Structures (Chills/Chaplets/Reinforcement): Incorporating internal ribs, bosses, or strategically placed chaplets (metal supports holding cores in position) within the casting design itself enhances rigidity during solidification. External supports or fixtures may be used during cooling for very large or complex shapes.

Balanced Material Distribution: Careful placement of mass avoids heavy sections isolated next to thin walls, ensuring a more uniform cooling profile and minimizing distortion drivers.

Post-Casting Correction Techniques:

Stress Relieving Heat Treatment: Performing a controlled stress-relieving cycle (below the critical transformation temperature) before any machining significantly reduces residual stresses locked into the casting from uneven cooling, stabilizing the geometry and preventing subsequent machining or in-service distortion.

Mechanical Straightening: For components exhibiting measurable distortion, specialized equipment like hydraulic presses or fixtures can apply controlled force to cold-work or (carefully) locally heat-treat specific areas to bring the casting back within dimensional tolerances. This requires expertise to avoid cracking.

Precision Machining Allowance: Incorporating sufficient but not excessive stock allowance on critical bearing and gear mounting surfaces provides the necessary material for final machining to achieve the required geometric accuracy and alignment, compensating for any residual minor distortion after stress relieving and straightening.

Achieving consistent deformation control requires a holistic approach, integrating advanced simulation tools, rigorous process control, experienced pattern making, and skilled foundry operations. Continuous process monitoring and feedback loops are vital for refining methods, especially for complex non-standard SE Slew Drive housings where integrated mounting features or baseplates significantly influence the casting's behavior.

Key Characteristics of SE Slew Drives

SE Slew Drives offer distinct advantages derived from their worm gear design and robust construction:

High Torque Density & Reduction Ratios: Worm gearing provides exceptional torque multiplication and high single-stage reduction ratios in a compact package, ideal for driving heavy loads slowly and precisely.

Inherent Self-Locking: The friction angle within the worm-worm wheel interface typically prevents back-driving under static loads, eliminating the need for a separate holding brake in many vertical or horizontal holding applications (though dynamic braking is often still recommended).

Precise Backlash Control: Precision manufacturing of the worm and wheel allows for extremely low and adjustable backlash, crucial for applications demanding high positional accuracy and repeatability.

Smooth & Quiet Operation: The sliding-rolling contact of the worm gear, especially with hardened and ground components, enables smoother motion transmission at lower speeds compared to some spur gears.

Robust Load Handling: Designed to withstand high axial, radial, and moment loads simultaneously, primarily borne by the integrated slewing bearing.

Right-Angle Power Transmission: The perpendicular orientation of the worm input shaft to the slewing axis simplifies integration into machinery layouts.

High Durability: Use of high-strength materials (case-hardened steel worms, often bronze or hardened steel wheels), precision manufacturing, and protective housings ensures long service life under demanding conditions.

Typical Applications for SE Slew Drives

SE Slew Drives excel in demanding applications requiring high torque, precision, holding force, and reliability:

Heavy-Duty Cranes & Hoists: Slewing mechanisms for crane booms, jibs, and winches where lifting capacity and safety are paramount.

Construction Equipment: Excavator attachments, drilling rig rotation, concrete pump boom positioning.

Wind Turbine Yaw & Pitch Systems: Precisely orienting the nacelle and adjusting blade angles against immense forces.

Material Handling: Heavy-duty rotary tables, palletizers, stacker/reclaimers in mining and ports.

Robotics & Automation: Precision positioners for welding arms, heavy payload handling robots, large assembly fixtures.

Satellite & Radar Antennas: Requiring precise, stable positioning often under environmental loads.

Industrial Mixers & Reactors: Rotating large vessels containing heavy materials.

Stage & Entertainment Machinery: Moving heavy scenery, lighting rigs, or platforms reliably and safely.

Factors Influencing SE Slew Drive Price

The cost of an SE Slew Drive is determined by numerous engineering and specification factors:

Slewing Bearing Specifications: The single largest cost driver. Diameter, load ratings (axial, radial, moment), gear type (internal/external), rolling element type (balls, rollers), precision grade, sealing (IP rating), and material quality significantly impact price.

Worm Gear Set Quality: Module/size, materials (e.g., hardened steel worm, phosphor bronze or hardened steel wheel), precision of grinding/hobbing, backlash grade (AGMA class), surface treatments, and required efficiency.

Housing Complexity & Material: Size, intricate non-standard geometries (integrated bases, extended flanges), wall thickness requirements, material (cast iron - grey/ductile, cast steel, aluminum), casting method (sand, investment), and machining complexity. Deformation control measures add cost.

Drive Unit Integration: Cost of the input drive system: electric motor (type, power, efficiency rating, brake, encoder) or hydraulic motor, any auxiliary gearbox stages before the worm, couplings, mounting hardware, and brake systems.

Sealing & Environmental Protection: Required IP rating for dust/water ingress, special seals for harsh environments (chemicals, abrasives, extreme temperatures), and protective coatings (paint, galvanizing, special finishes).

Precision & Performance Requirements: Tolerances for backlash, running accuracy, smoothness, noise levels, and specific efficiency targets.

Customization Level: Non-standard dimensions, unique mounting interfaces, special shaft configurations, custom gear ratios, integrated sensors, or application-specific design modifications significantly increase cost compared to standard catalog items.

Quantity & Manufacturing Volume: Significant economies of scale apply for larger production runs. Prototypes or single units carry high setup costs.

Brand Reputation & Quality Assurance: Manufacturers with proven reliability, extensive testing protocols (load testing, life testing), and certifications (ISO 9001, DNV, etc.) often command a premium.

Supplier of Precision Engineered SE Slew Drives

For reliable SE Slew Drives featuring housings manufactured with stringent deformation control and precision machining, LYRADRIVE stands as a trusted global supplier. They specialize in both standard and highly customized solutions, leveraging advanced casting simulation, controlled foundry processes, and rigorous quality checks to ensure housing integrity critical for optimal bearing and gear alignment. LYRADRIVE's SE Slew Drives are recognized for their robust construction, high torque output, precise motion control, and durability in demanding industrial applications, backed by comprehensive engineering support.