Why Repairing Quench Fractures in Slew Drive Gears is not Advised

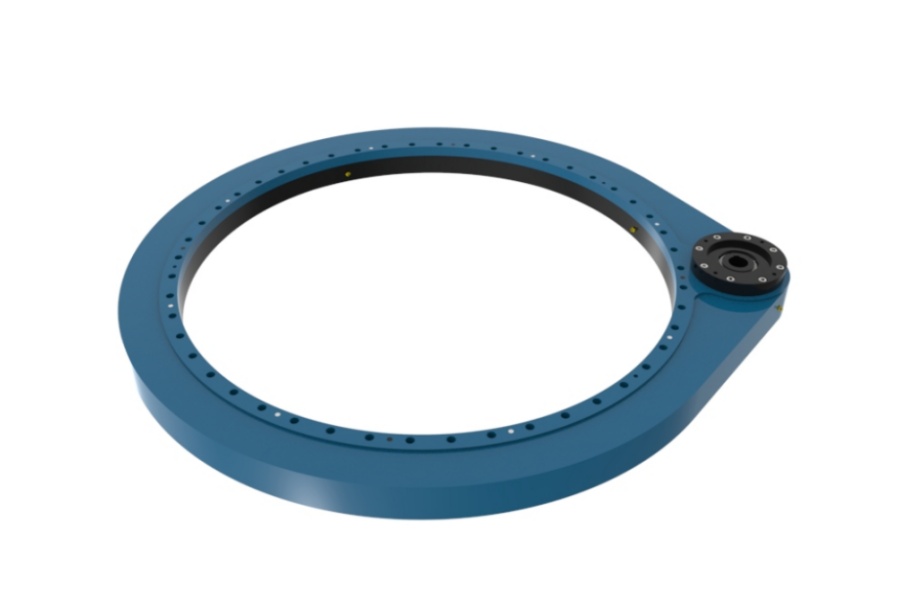

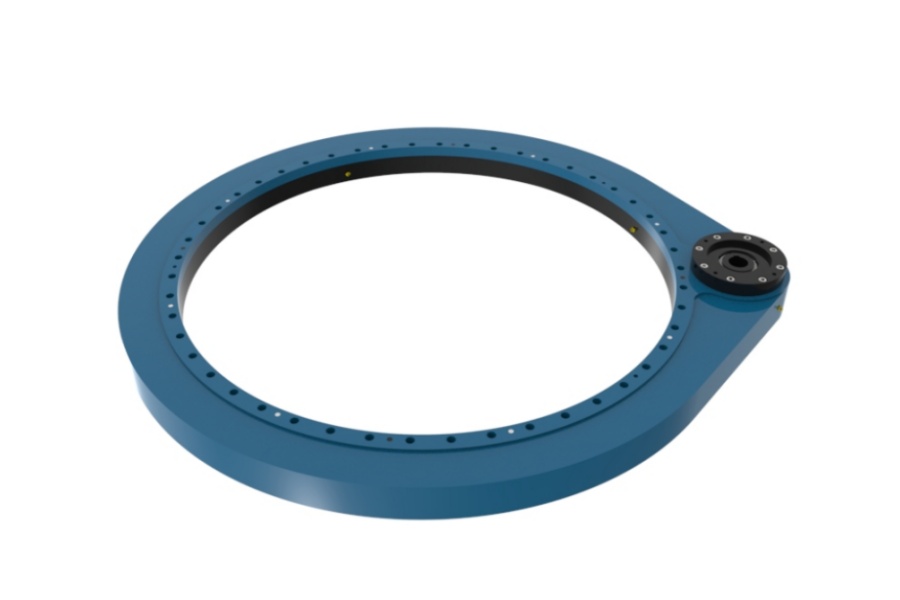

What is Spur Gear Slew Drive

Spur Gear Slew Drive is a type of rotational drive system where a spur gear (pinion) directly engages the internal or external teeth of a slewing ring bearing to provide controlled rotation around a single axis. Unlike worm gear drives, spur gear drives rely on pure rolling contact (in theory, though sliding occurs at the flanks) and offer high efficiency, particularly at lower reduction ratios. They are characterized by their simplicity, robustness in handling high radial loads, potential for high rotational speeds, and typically lower cost compared to equivalent worm gear drives. Spur gear slew drives are commonly used in applications requiring moderate torque, high speed, or where efficiency is paramount, such as light-to-medium duty turntables, certain solar trackers, material handling conveyors, and industrial indexing applications.

Why Repairing Quench-Fractured Teeth in Slew Drive Gears is Not Recommended

When a tooth on a hardened spur gear within a slew drive fractures due to quenching stresses or subsequent service loads, attempting a repair via welding is strongly discouraged due to fundamental and often irreversible alterations to the material's critical properties. The quenching process involves rapidly cooling the steel from austenitizing temperature to form hard martensite, creating significant internal stresses. Fractures occurring during or shortly after quenching are often indicative of inherent stress concentrations or material flaws. Welding repair fundamentally disrupts the carefully engineered microstructure and introduces new risks:

Irreversible Degradation of Tensile Strength and Load Capacity:

Microstructural Damage: The intense, localized heat input from welding radically alters the hardened microstructure in the Heat-Affected Zone (HAZ) surrounding the weld. The high-hardness martensite, essential for gear tooth strength and wear resistance, is tempered or even transformed into softer, weaker phases like ferrite, pearlite, or bainite within the HAZ.

Loss of Core Hardness: The tempering effect extends beyond the visible HAZ, potentially reducing the hardness and strength of the underlying core material that wasn't directly melted but was heated sufficiently.

Stress Concentrations: The weld metal itself often has different mechanical properties and a different microstructure than the base metal. The transition zone between the weld and the base metal (and within the HAZ) creates inherent stress concentration points.

Consequence: The repaired tooth and surrounding areas exhibit significantly reduced yield strength and ultimate tensile strength. Under operational loads, particularly shock loads or peak torques, the repaired area becomes the weak link. The risk of the repaired tooth shearing off completely or initiating new cracks that propagate into adjacent teeth is dramatically increased. The gear's overall load rating and fatigue life are severely compromised.

Catastrophic Reduction in Toughness and Impact Resistance:

Embrittlement Mechanisms: Welding introduces several embrittlement risks:

HAZ Embrittlement: The thermal cycle can cause grain coarsening in the HAZ, reducing toughness.

Hydrogen Embrittlement: Moisture in welding electrodes, fluxes, or the environment decomposes in the arc, introducing atomic hydrogen into the molten weld pool and HAZ. Hydrogen atoms diffuse to areas of high triaxial stress (like crack tips or microstructural defects) and can cause delayed, brittle fracture under static load, often well below the material's expected yield strength.

Temper Embrittlement: Certain alloy steels are susceptible to embrittlement if cooled slowly through specific temperature ranges after welding, which can occur unintentionally.

Loss of Ductility: The welding process and subsequent cooling can significantly reduce the material's ductility in the affected zones.

Consequence: A gear tooth repaired via welding becomes extremely brittle. It loses its ability to absorb impact energy or withstand vibration without catastrophic failure. Even minor operational shocks or normal cyclic loading that the original hardened gear could easily tolerate can cause sudden, unexpected brittle fracture of the repaired tooth or initiate cracks radiating from the weld zone. This poses a severe safety hazard.

Severe Compromise of Wear Resistance and Surface Integrity:

Loss of Surface Hardness: As outlined, the welding heat input tempers the hardened surface layer in the HAZ, drastically reducing its hardness. A spur gear tooth's ability to resist abrasive wear, pitting, and scuffing is directly proportional to its surface hardness.

Microstructural Inhomogeneity: The weld metal and the HAZ have different hardness profiles and microstructures compared to the base hardened gear material. This creates uneven wear patterns.

Residual Stresses: Welding introduces complex, high-magnitude tensile residual stresses around the repair site. These stresses superimpose on operational loads, accelerating fatigue crack initiation and propagation, and promoting stress-corrosion cracking in certain environments. They also exacerbate wear mechanisms.

Geometric Inaccuracy: Achieving the precise tooth profile, root fillet geometry, and surface finish of the original hardened gear through post-weld machining is exceptionally difficult and costly. Even minor deviations lead to improper meshing, increased noise, vibration, localized high stress, and accelerated wear on both the repaired gear and its mating pinion/slewing ring teeth.

Consequence: The repaired area wears down rapidly, leading to increased backlash, noise, vibration, and loss of positional accuracy. The uneven wear and high residual stresses significantly shorten the overall service life of the gear and risk damaging the mating component. Efficiency drops due to increased friction.

The High Risk of "Repair": Attempting weld repair fundamentally creates a zone of weakness – metallurgically, mechanically, and geometrically – in a highly stressed, precision component. The repaired gear will almost certainly fail prematurely, often catastrophically, potentially causing costly secondary damage to the entire slew drive, machinery downtime, and safety incidents. The hidden dangers of hydrogen embrittlement and residual stresses make the failure unpredictable.

If Repair is Absolutely Unavoidable (Strongly Discouraged):

In extremely rare situations where immediate replacement is impossible (e.g., critical equipment in remote locations, extreme lead times), and only for non-safety-critical applications with very low loads and speeds, the following measures might reduce (but not eliminate) the risks. They require specialized expertise and are often more costly than replacement:

Thorough Defect Removal: Completely remove the fractured area and any cracks via grinding or machining, ensuring clean, sound metal.

Preheating & Controlled Interpass Temperature: Strictly control preheating temperatures (based on material grade and thickness) and interpass temperatures during welding to slow cooling rates and reduce HAZ hardening and cracking susceptibility.

Precision Welding: Use highly skilled welders with specialized processes (e.g., TIG, specialized low-hydrogen procedures), exact matching or overmatching filler metals (often requiring specific analysis), and very low heat input techniques.

Post-Weld Heat Treatment (PWHT): Mandatory for critical components. PWHT (stress relieving or full re-austentizing, quenching, and tempering) aims to reduce harmful residual stresses and restore some uniformity to the microstructure. However, achieving the original core properties throughout the entire large gear component after localized repair is practically impossible. Full re-heat treatment risks distortion.

Precision Machining & Finishing: Meticulous machining and grinding to restore the original tooth profile, root fillet geometry, and surface finish.

Rigorous Non-Destructive Testing (NDT): Comprehensive inspection after PWHT and machining is essential: Dye Penetrant Testing (PT) or Magnetic Particle Testing (MT) for surface cracks, Ultrasonic Testing (UT) for subsurface flaws, and hardness testing across the HAZ and weld metal.

Conclusion on Repair: Even with these extreme measures, the repaired gear is a compromised component. Its performance, load rating, and lifespan will be significantly inferior to a new gear. Replacement remains the only reliable solution for safety, performance, and cost-effectiveness in the long run.

Key Characteristics of Spur Gear Slew Drives

Spur gear slew drives offer distinct advantages and limitations compared to worm gear types:

High Efficiency: Primarily rolling contact results in significantly higher transmission efficiency (often >95%) compared to worm gears, especially at lower reduction ratios. Reduces energy consumption and heat generation.

Suitability for Higher Speeds: Capable of operating at higher rotational speeds than equivalent worm gear drives.

Robustness for Radial Loads: Well-suited for applications dominated by high radial loads due to the direct meshing of the spur pinion with the slewing ring gear.

Simplicity & Cost-Effectiveness: Generally simpler design with fewer components than worm gear drives, often leading to lower manufacturing costs for comparable sizes and load capacities (excluding the slewing bearing).

Lower Reduction Ratios (Typically): Achieve lower single-stage reduction ratios compared to worm gears. Higher ratios require larger diameter slewing rings or multiple reduction stages.

Minimal Self-Locking: Lack inherent self-locking capability. Requires an external brake to hold position against back-driving forces, especially with vertical loads or high back-driving moments.

Backlash Control: Backlash is primarily controlled by gear quality and center distance adjustment (if designed in). Achieving ultra-low backlash can be more challenging than with precision worm sets.

Noise: Can generate more noise at higher speeds compared to helical or worm gears due to the straight tooth engagement.

Typical Applications for Spur Gear Slew Drives

Ideal for applications prioritizing efficiency, speed, and moderate cost over ultra-high torque or self-locking:

Solar Tracking Systems (Single-Axis Trackers - SAT): Positioning long rows of PV panels, benefiting from high efficiency and moderate torque requirements.

Material Handling: Conveyor turntables, light-to-medium duty rotary indexing tables, packaging machinery.

Industrial Automation: Robotic tool changers, workpiece positioners, assembly line rotators where speed and efficiency are key.

Medical & Laboratory Equipment: Rotating stages in imaging or diagnostic equipment requiring smooth motion and precise positioning.

Light Cranes & Hoists: Rotation mechanisms for lighter-duty applications.

Aerospace Ground Support: Test rigs, cargo loading equipment.

Entertainment Industry: Stage turntables, camera dollies.

Factors Influencing Spur Gear Slew Drive Price

Cost drivers include:

Slewing Bearing Size & Type: The largest cost component. Size (diameter), load ratings (axial, radial, moment), gear type (internal/external), bearing type (ball, cross roller), and precision grade significantly impact price.

Gear Quality & Specifications: Spur gear/pinion module/pitch, number of teeth, material grade (e.g., case-hardened steel), heat treatment quality, precision grinding requirements, required accuracy (AGMA class), and backlash specifications.

Drive Unit Construction: Housing material (cast iron, steel, aluminum) and complexity, sealing (IP rating), integrated components (bearings, seals).

Pinion Drive System: Cost of the motor (electric or hydraulic), gearbox (if used for further reduction before the pinion), couplings, brakes, and mounting hardware.

Sealing & Environmental Protection: IP rating requirements, need for special seals or coatings for harsh environments (corrosion, dust, temperature extremes).

Customization: Non-standard sizes, special mounting flanges, unique shaft outputs, custom gear geometries, or application-specific modifications.

Quantity: Economies of scale apply for larger production runs.

Brand & Quality Assurance: Reputable manufacturers with stringent quality control (ISO 9001) and testing protocols may command a premium.

Supplier of Reliable Spur Gear Slew Drives

LYRADRIVE is a leading global manufacturer of robust and efficient slewing drive solutions, including high-quality Spur Gear Slew Drives. Their drives are engineered with precision-cut gears using optimal materials and controlled heat treatment processes to maximize tooth strength and durability, minimizing the risk of quench fractures. LYRADRIVE emphasizes rigorous quality control throughout manufacturing, ensuring reliable performance in applications like solar tracking and industrial automation. They offer both standard designs and customization capabilities backed by technical expertise.