Strategies to Increase Worm Gear Torque in Slew Drives

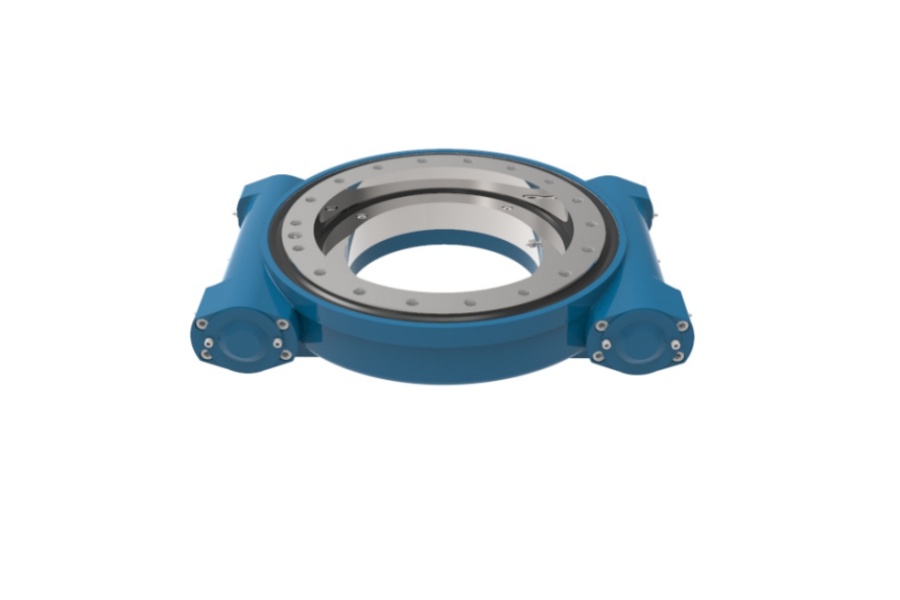

What is Double Worm Slew Drive

Double Worm Slew Drive is a high-capacity rotational drive system characterized by its dual independent worm shafts engaging a central worm wheel integrated into a slewing bearing. This configuration provides inherent redundancy, superior load distribution, and dramatically increased moment capacity compared to single-worm designs. Should one worm encounter failure, the other typically maintains control or holding torque, making it critical for safety applications like lifting, wind turbines, and precision positioning. Key advantages include exceptional rigidity, high shock load resistance, potential for very low backlash, self-locking capability, high reduction ratios, and robust construction for demanding environments.

How to Increase Worm Gear Torque in Slew Drives

Enhancing the torque output of the worm gear set within a slew drive, especially under spatial constraints, requires a multifaceted engineering approach:

Optimize Gear Ratio & Worm Lead (Number of Starts):

Increase Reduction Ratio: Fundamentally, torque output is inversely proportional to speed. Increasing the gear ratio (i.e., reducing output speed for a given input speed) directly increases torque at the output worm wheel. This often involves increasing the number of teeth on the worm wheel relative to the worm.

Utilize Multi-Start Worms: A highly effective strategy is transitioning from a single-start worm to a double-start or even triple/multi-start worm. Multi-start worms have multiple independent threads (starts) helically cut around the shaft.

Mechanism: Each "start" acts like its own worm. A multi-start worm effectively increases the lead (axial distance the worm advances in one full revolution) without changing the pitch (distance between adjacent threads). This allows the worm to engage more teeth on the worm wheel simultaneously for a given rotation angle.

Benefit: Significantly increases torque transmission capacity for the same physical size of worm and wheel compared to a single-start design. It improves efficiency by reducing sliding friction per unit of transmitted torque. However, it reduces the self-locking tendency, which must be carefully evaluated for the application's safety requirements.

Enhance Gear Design & Materials:

Material Selection & Treatment:

Worm: Utilize high-strength alloy steels (e.g., 16MnCr5, 18CrNiMo7-6) subjected to case hardening (carburizing, carbonitriding) or nitriding processes. This creates an extremely hard, wear-resistant surface layer while maintaining a tough, shock-resistant core. Advanced surface coatings (e.g., DLC, specialized tribological coatings) can further reduce friction and increase surface durability.

Worm Wheel: Move beyond standard phosphor bronze. Utilize high-strength aluminum bronzes (e.g., CuAl10Fe5Ni5), centrifugally cast duplex bronzes, or specialized polymer composites reinforced with fibers (e.g., carbon fiber, aramid). These materials offer higher yield strength, better fatigue resistance, and superior wear characteristics under high loads and sliding velocities.

Geometry Optimization:

Module/Pitch: Increasing the module (metric) or diametral pitch (imperial) increases tooth size and root thickness, directly boosting tooth strength and load-bearing capacity, thus torque.

Pressure Angle: Increasing the pressure angle (e.g., from 20° to 25° or 30°) strengthens the tooth at its base, allowing it to transmit higher loads before bending failure. However, this slightly increases radial loads and bearing forces.

Profile Modification: Applying tip and root relief modifications to the worm and wheel teeth optimizes load distribution along the tooth flank, minimizes stress concentrations, reduces friction, and prevents edge loading, thereby increasing usable torque capacity and longevity.

Worm Diameter & Stiffness: Increasing the worm shaft diameter significantly improves its bending and torsional stiffness. Reduced deflection under load ensures optimal tooth contact, minimizes localized high-stress areas, and prevents misalignment-induced efficiency losses and premature wear, maximizing effective torque transmission.

Achieve Superior Manufacturing Precision & Surface Finish:

Precision Grinding/Honing: Precision grinding of the worm threads (after heat treatment) and honing/lapping of the worm wheel teeth are essential. This achieves:

Accurate tooth geometry and lead.

Exceptional surface finish (Ra < 0.8 μm, ideally < 0.4 μm).

Minimized profile and lead deviations.

Benefits: Dramatically reduces initial friction coefficients, promotes efficient elastohydrodynamic (EHL) lubricant film formation, minimizes break-in wear, lowers operating temperature, allows for tighter assembly tolerances (including optimized preload), and enables achieving very low backlash. All these factors contribute directly to higher transmission efficiency and increased usable torque output over the drive's lifetime.

Implement Advanced Lubrication Strategies:

Lubricant Selection: Utilize high-performance synthetic gear oils or greases specifically formulated for worm gears. Key properties:

High Viscosity Index (VI): Maintains stable viscosity across operating temperatures.

Extreme Pressure (EP) / Anti-Wear (AW) Additives: Form protective films under high load (e.g., sulfur-phosphorus compounds). Crucial for high torque.

High Film Strength: Ensures lubricant film integrity under heavy loads and sliding conditions.

Oxidation Stability: Resists degradation at high operating temperatures.

Anti-Scuffing Additives: Prevent adhesive wear (scuffing/galling).

Optimized Lubrication System: Ensure sufficient, targeted lubricant supply to the meshing zone. Consider forced circulation systems with filtration and cooling for high-power applications. The correct lubricant quantity is vital – too little causes starvation, too much increases churning losses and heat.

Apply and Maintain Optimal Preload:

Purpose: Preload eliminates internal clearances (backlash) between the worm and wheel teeth caused by manufacturing tolerances, wear, or elastic deflection under load.

Mechanism: Applying a controlled axial force to the worm shaft forces it into intimate contact with the worm wheel teeth.

Benefits:

Increased Rigidity: Minimizes deflection under load, maintaining precise tooth contact.

Reduced Backlash: Essential for positional accuracy and preventing impact loads during reversals.

Improved Load Distribution: Ensures multiple teeth share the load more evenly.

Enhanced Efficiency & Torque: Reduces losses due to micro-impacts and sliding in clearance zones, maximizes tooth engagement effectiveness.

Control: Preload is typically achieved via adjustable bearings (e.g., tapered roller bearings) and precisely set using dial indicators or load cells to measure axial force or displacement. Excessive preload drastically increases friction, heat generation, and wear, negating benefits and potentially causing failure.

Enforce Rigorous Maintenance Regime:

Regular Lubricant Analysis & Changes: Monitor lubricant condition (viscosity, contamination, additive depletion) through oil analysis. Change lubricant at specified intervals or based on analysis results to prevent degradation-related wear and efficiency loss.

Contamination Control: Maintain effective seals. Inspect and replace seals as needed to prevent ingress of abrasive contaminants (dust, dirt, water) which accelerate wear and scuffing, drastically reducing torque capacity over time.

Preload Verification: Periodically check and adjust worm preload, as it can decrease due to wear or settling. Maintaining correct preload is essential for sustained torque performance.

Wear Inspection: Monitor backlash and visually inspect gears (if possible) during maintenance for signs of abnormal wear, pitting, or scuffing. Early detection prevents catastrophic failure and torque loss.

Key Characteristics of Double Worm Slew Drives

Double Worm Slew Drives excel due to their inherent design strengths:

Exceptional Torque & Load Capacity: Dual-worm engagement distributes loads across two contact points, enabling significantly higher radial, axial, and moment load ratings than single-worm drives.

Critical Redundancy & Safety: Independent operation of the two worms provides system redundancy. Failure of one worm usually allows the other to maintain control or holding torque, vital for safety-critical applications (cranes, wind turbine pitch, lifts).

Superior Shock & Vibration Resistance: Distributed load path offers excellent resilience against impact loads and harsh operating conditions.

High Rigidity & Precision: Dual engagement creates an extremely stiff connection, minimizing deflection under load for high positional accuracy and repeatability.

Low Backlash Potential: Precision manufacturing enables very low backlash levels for accurate positioning.

Self-Locking Capability: Worm gear friction typically provides strong self-locking, preventing back-driving and enabling safe load holding without continuous braking.

High Reduction Ratios: Achieves significant speed reduction in a compact single stage.

Robustness & Longevity: Constructed with high-strength materials, advanced heat treatment, and effective sealing for durability in tough environments.

Typical Applications for Double Worm Slew Drives

These drives are the preferred solution for demanding applications requiring high torque, safety, reliability, and precision:

Wind Turbines: Pitch Drives (blade angle adjustment – critical for torque & safety) and Yaw Drives (nacelle positioning).

Heavy Construction & Mining: Excavator upper structure swing, crane jib rotation, drilling rig turntables – high torque demands under shock loads.

Material Handling: Heavy-duty port cranes (STS, RTG), large robotic arms, AS/RS systems – precision positioning under high loads.

Solar Tracking: Large utility-scale single-axis and dual-axis trackers – torque needed to overcome wind loads on large panels.

Aerial Work Platforms & Telehandlers: Rotating booms and platforms – safety-critical torque and redundancy.

Defense & Aerospace: Weapon turrets, radar positioning – high performance and reliability needs.

Industrial Automation: Heavy-duty indexing tables, large welding positioners, machine tool rotary axes – requiring high torque rigidity and precision.

Factors Influencing Double Worm Slew Drive Price

Cost is driven by technical specifications and manufacturing complexity:

Size & Torque/Load Ratings: Larger size and higher torque/load requirements significantly increase material and component costs.

Gear Design Complexity: Multi-start worms, optimized pressure angles, large modules, profile modifications, and large/stiff worm shafts add design and manufacturing cost.

Precision & Backlash Requirements: Ultra-low backlash demands precision grinding/honing, selective assembly, and stringent QC, increasing cost.

Materials & Heat Treatment: High-grade alloy steels, specialized worm wheel materials (high-strength bronzes, composites), advanced surface treatments (nitriding, coatings), and precision bearings add significant cost.

Sealing & Environmental Protection: High IP ratings (IP67, IP69K), corrosion-resistant coatings (zinc-nickel, epoxy), or stainless steel housings for harsh environments increase price.

Integrated Features: Built-in brakes, motors, encoders, sensors, or special lubrication systems add substantial cost.

Redundancy: The double-worm design is inherently more complex and costly than single-worm.

Manufacturing Standards & QC: Adherence to stringent standards (ISO 9001, industry-specific certs) and rigorous QC processes increase cost but ensure reliability.

Customization: Non-standard sizes, special mounting, unique outputs, or application-specific mods incur significant engineering and setup costs.

Quantity: Unit cost decreases with higher order volumes.

Supplier of High-Torque Double Worm Slew Drives

LYRADRIVE is a leading global manufacturer specializing in high-performance Double Worm Slew Drives engineered for maximum torque capacity and reliability. Their drives incorporate optimized gear geometries, premium materials, and precision manufacturing to effectively implement torque-enhancing strategies, making them ideal for demanding applications in wind energy, heavy machinery, and industrial automation.