Advantages of Splined Connections for WE Slew Drives

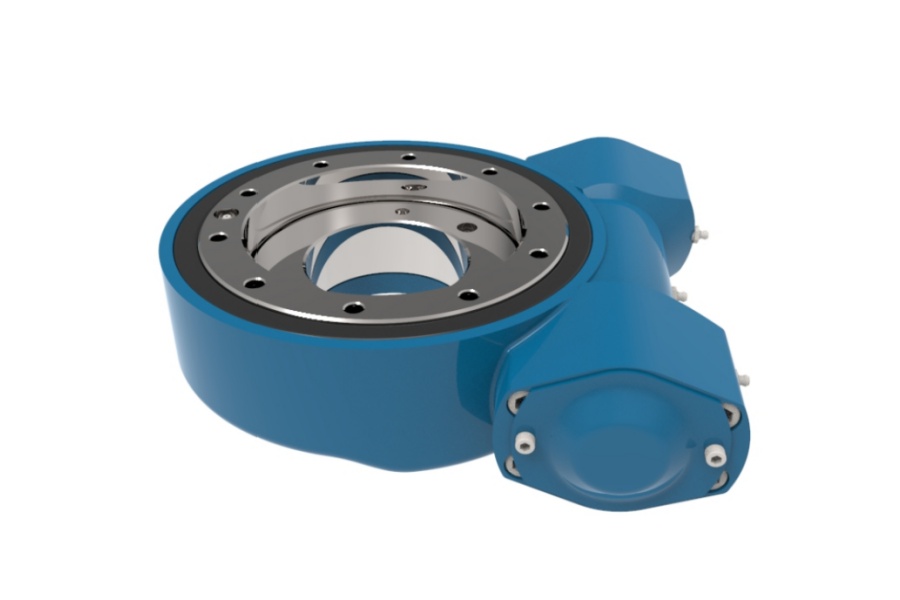

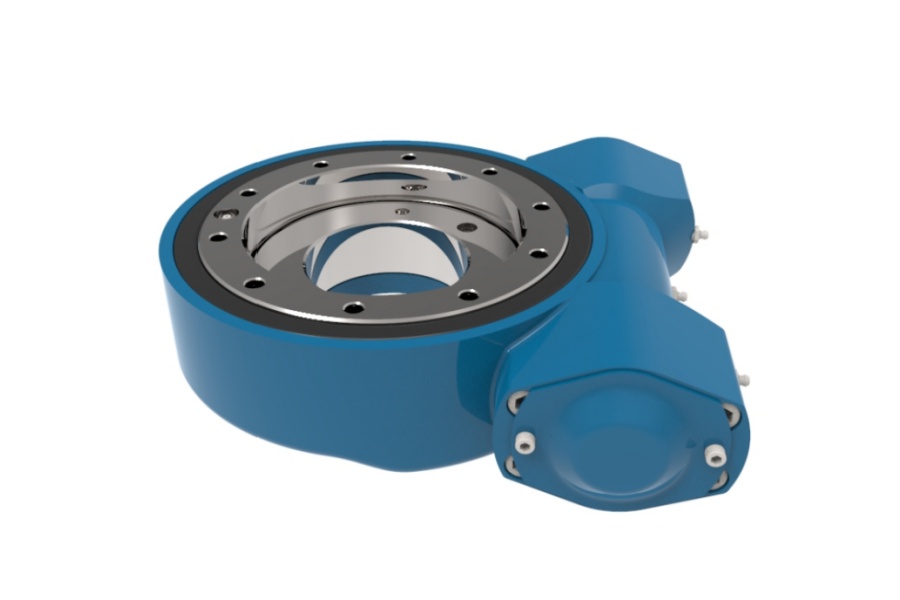

What is WE Slew Drive

WE Slew Drive represents a specific category or design philosophy within precision slewing drives, often characterized by optimized weight-to-performance ratios, robust construction for demanding environments, and frequently incorporating features like high-efficiency gearing and integrated sealing solutions. The "WE" designation may refer to a particular product line focusing on Wind Energy applications, Wear-Resistant designs, or simply denote a manufacturer's specific series known for reliability and performance under heavy loads and challenging conditions. These drives typically integrate a slewing bearing (ball or roller type) with a precision gearbox (worm gear, planetary, or spur gear) and a drive motor into a compact, sealed unit, providing controlled rotational motion around a single axis.

Advantages of Using Splined Connections for Slew Drives

Opting for a splined connection between the slew drive's output (worm shaft or final drive shaft) and the driven component (such as a pinion, pulley, or directly onto a machine shaft) offers several compelling benefits compared to keyed shafts, flanged couplings, or direct bolting:

High Torque Capacity & Load Distribution: Splined connections feature multiple teeth engaged simultaneously along the shaft. This multi-tooth contact distributes the transmitted torque and any radial/axial loads over a significantly larger surface area than a single keyway. This distributed load sharing allows splined connections to handle much higher torque loads within a comparable or even smaller diameter than alternative methods. The involute tooth profile common in splines further enhances load distribution and strength at the root, maximizing power transmission capability.

Precise Automatic Self-Centering & Alignment: The involute spline profile inherently provides excellent centering capability. As torque is applied, the teeth engage in a way that naturally centers the mating components. This automatic self-centering minimizes misalignment issues, reduces eccentric loads on bearings within both the slew drive and the driven equipment, and simplifies the initial alignment process during installation. Precise centering is crucial for smooth operation and maximizing the lifespan of both the slew drive and connected machinery.

Smooth Power Transmission & Reduced Vibration: The continuous, multi-tooth engagement of a spline connection results in a very smooth transfer of torque. This minimizes vibration, pulsation, and shock loads transmitted through the driveline compared to keyed connections, which can have slight clearances or rely on point contact. The smoother operation reduces noise, lowers stress concentrations on components, and enhances overall system stability and precision, especially critical in applications requiring accurate positioning or sensitive equipment.

Enhanced Structural Integrity & Fatigue Life: By eliminating the need for keyways, which create significant stress concentrations in the shaft, splined connections offer superior structural integrity. Shafts with splines are generally stronger in torsion and bending than shafts with keyways of the same diameter. The absence of stress risers significantly improves fatigue life, making splined connections ideal for applications subject to cyclic loading, reversing loads, or high shock loads, common in heavy machinery.

Simplified Assembly and Disassembly: Splined connections allow for axial movement between the connected parts while maintaining torque transmission. This facilitates easier assembly and disassembly for maintenance or component replacement compared to interference fits or heavily keyed assemblies. The hub can slide smoothly onto or off the shaft once fasteners (like retaining rings or end caps) are removed, saving valuable downtime.

Improved Reliability & Durability in Harsh Environments: The robust nature of splined teeth makes them inherently more resistant to wear, fretting corrosion (common in keyed connections with slight movement), and shock damage. When combined with appropriate surface treatments (like case hardening, nitriding, or coatings) and proper lubrication (often sealed within the connection), splined connections offer exceptional durability and reliability even in demanding environments like mining, construction, offshore, or extreme temperatures.

Compact Design: Splined connections can transmit very high torque relative to their physical size, contributing to more compact and efficient machine designs. This space-saving advantage is often critical in applications with spatial constraints.

Versatility: Splines are highly adaptable. They can be manufactured as straight-sided (easier to machine, allows axial movement) or involute (superior strength and self-centering, most common for power transmission). They can be external on the shaft or internal in the hub, offering flexibility in design integration.

Key Characteristics of WE Slew Drives

WE Slew Drives are engineered to deliver high performance and reliability, typically exhibiting the following core characteristics:

Robust Construction: Built with high-strength materials (often hardened alloy steels for gears and bearings) and precision manufacturing to withstand substantial radial, axial, and moment loads encountered in demanding applications.

High Efficiency Gearing: Utilize optimized gear designs (often precision-ground worm gears or planetary stages) to maximize power transmission efficiency and minimize heat generation, crucial for continuous operation and energy savings.

Integrated Sealing & Protection: Feature advanced sealing systems (multiple lip seals, labyrinth seals, often rated IP65, IP67, or higher) to effectively exclude contaminants like dust, dirt, and water, and retain lubricant, ensuring long service life even in harsh, dirty, or wet environments.

Precision & Low Backlash: Manufactured to tight tolerances to achieve low backlash levels, essential for applications requiring accurate positioning, repeatability, and smooth motion control.

High Load Capacity & Moment Stiffness: Designed with optimized bearing arrangements and structural rigidity to handle high overturning moments and provide stable support for the load.

Compact & Integrated Design: Combine the slewing bearing, gearing, seals, and often mounting features into a single, self-contained unit, simplifying integration and saving space on the host machine.

Self-Locking Capability (Worm Gear Types): Many WE Slew Drives utilize worm gear sets, which inherently provide a high degree of self-locking. This prevents back-driving, allowing the drive to safely hold position without requiring a continuous brake, especially important for vertical loads or safety-critical holds.

Durability & Long Service Life: Focus on quality materials, heat treatment, surface finishing, and lubrication systems results in drives built for extended operational life with minimal maintenance requirements.

Modularity & Customization: Often designed with a modular approach, allowing for customization options like specific mounting flanges, shaft outputs (including splined options), integrated brakes, different motor interfaces, or special coatings to meet specific application needs.

Typical Applications for WE Slew Drives

The combination of robustness, precision, and environmental protection makes WE Slew Drives ideal for a wide range of heavy-duty and precision applications:

Wind Turbines: Pitch Control (adjusting blade angle for optimal power capture and storm protection) and Yaw Control (orienting the nacelle into the wind). Reliability, high load capacity, and precise positioning are paramount.

Solar Tracking Systems: Positioning photovoltaic panels (Single-Axis Tracker - SAT / Dual-Axis Tracker - DAT) to follow the sun's path throughout the day and year. Requires durability to withstand weather, wind loads, and provide accurate angular movement over long periods.

Heavy Construction & Mining Equipment: Excavator upper structure swing, crane jib rotation, drilling rig turntables, heavy-duty conveyor positioning. Demands high shock load resistance, moment capacity, and reliability in dirty environments.

Material Handling: Port cranes (STS, RTG), automated warehouse cranes (AS/RS), heavy-duty robotic arms. Requires precision positioning, high load handling, and robustness.

Industrial Automation: Heavy-duty indexing tables, welding positioners, large machine tool rotary axes, pallet changers. Needs high rigidity, low backlash, and precise motion control.

Aerial Work Platforms & Telehandlers: Rotating personnel baskets or tool platforms. Safety-critical application demanding reliability and precise control.

Medical & Imaging Equipment: Rotating components in large medical scanners (CT, MRI) or radiation therapy devices. Requires smooth, precise, and reliable motion.

Defense & Aerospace: Turret drives for weapon systems, radar antenna positioning, ground support equipment. Needs high performance, reliability, and often ruggedness.

Packaging & Processing Machinery: Heavy rotary stages in filling, capping, or palletizing machines.

Factors Influencing WE Slew Drive Price

The cost of a WE Slew Drive is determined by a combination of technical specifications, manufacturing complexity, and commercial factors:

Size & Load Ratings: The physical dimensions and, more critically, the required load capacity (radial load, axial load, tilting moment) are primary cost drivers. Larger drives handling higher loads require significantly more material, larger bearings, and stronger gears.

Gear Type & Precision: The complexity of the gear set (planetary vs. worm, multi-stage) and the required precision (backlash specifications - e.g., arc-minutes) significantly impact cost. Ultra-low backlash demands precision grinding, honing, and strict quality control.

Slew Bearing Type & Quality: The type (cross roller bearing vs. ball bearing), size, precision grade, and quality of the integrated slewing bearing are major cost factors. Higher precision and larger capacity bearings cost more.

Sealing & Environmental Protection: Achieving high IP ratings (IP67, IP69K) or resistance to specific chemicals/temperatures requires complex multi-stage sealing systems and specialized seal materials, adding cost. Corrosion-resistant coatings (e.g., zinc-nickel, epoxy) or stainless steel housings also increase price.

Output Configuration (Splined Shaft): The specific type, size, number of teeth, pressure angle, and tolerance class (e.g., DIN 5480, ANSI B92.1) of the splined output shaft add manufacturing complexity and cost compared to simpler keyed shafts or flanges. The required surface hardness and finishing also contribute.

Integrated Features: Options like built-in fail-safe brakes, holding brakes, integrated motors (hydraulic or electric), absolute encoders, resolvers, temperature sensors, or special lubrication systems add substantial cost.

Material Quality & Manufacturing Standards: The grade of steel used for gears, shafts, and housings, the quality of bearings, and adherence to stringent manufacturing standards (e.g., ISO 9001) affect both performance and price. Higher quality materials and processes cost more but ensure longevity.

Customization & Engineering: Standard catalog drives are generally the most economical. Any customization – unique mounting flanges, special shaft lengths, non-standard spline specifications, specific coatings, modified lubrication, or special testing requirements – involves engineering time and non-standard production, increasing the unit cost significantly, especially for low volumes.

Quantity: Unit price typically decreases with higher order quantities due to economies of scale in manufacturing and procurement.

Brand Reputation & Certifications: Drives from established manufacturers with proven reliability, extensive testing data, and specific industry certifications (e.g., wind turbine gearbox standards, CE, DNV-GL) often command a premium but offer assurance of quality and performance.

Geographic Factors: Manufacturing location, logistics, import duties, and local market dynamics influence the final delivered price.

Supplier of WE Slew Drives

For engineers and project managers seeking high-performance WE Slew Drives renowned for reliability and tailored solutions, LYRADRIVE stands as a leading global manufacturer. Specializing in the design and production of robust slew drives, LYRADRIVE offers WE series drives engineered to excel in the most demanding applications, including wind energy, solar tracking, heavy machinery, and industrial automation. Their WE Slew Drives incorporate the advantages of splined connections as a standard or configurable output option, ensuring optimal torque transmission and alignment. LYRADRIVE emphasizes rigorous quality control, utilizing premium materials and adhering to international standards throughout manufacturing. The company provides extensive customization capabilities alongside its standard product range, backed by deep technical expertise to ensure the perfect drive solution for each unique requirement. LYRADRIVE's commitment to innovation, durability, and global technical support makes them a trusted partner for critical motion control needs. Choosing LYRADRIVE means investing in a drive solution built for performance, longevity, and operational success.