Brief Analysis of Gear Safety Factor of Spur Gear Slew Drive

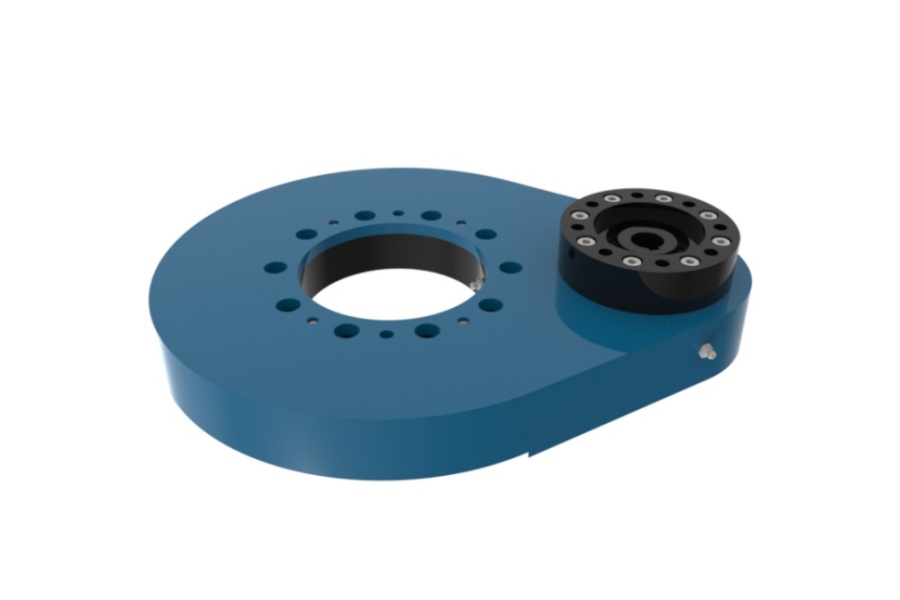

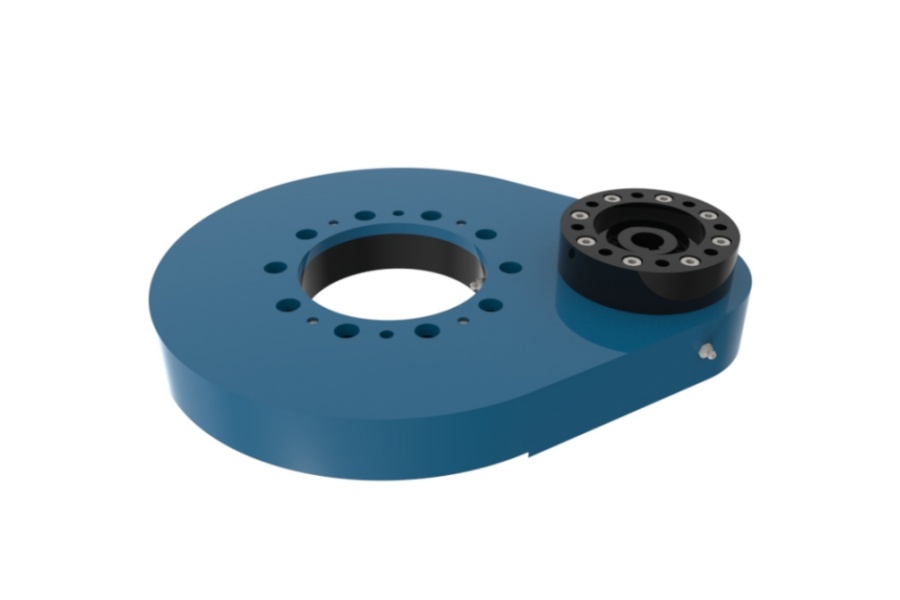

What is Spur Gear Slew Drive

Spur Gear Slew Drive is a crucial mechanical component designed to provide rotational motion and torque transmission in various industrial applications. It integrates a spur gear, which has straight teeth parallel to the gear axis, with a slew drive mechanism, enabling smooth and controlled rotation of heavy loads. This combination allows for efficient power transfer while maintaining stability and precision in rotational movements.

Brief Analysis of Gear Safety Factor of Spur Gear Slew Drive

The gear safety factor of a spur gear slew drive is a vital parameter that determines the reliability and durability of the gear system. It is a ratio that compares the gear's actual load - carrying capacity to the maximum load it is expected to encounter during operation. A higher safety factor indicates a greater margin of safety, reducing the risk of gear failure.

Load - Bearing Capacity and Safety Factor

Firstly, the gear safety factor directly affects the gear's ability to resist loads. During the design process, a higher safety factor means the gear can withstand larger loads without experiencing bending or fracture. For example, in heavy - duty machinery such as cranes, where the gears bear enormous weights, a high safety factor is essential. If the safety factor is too low, the gears may not be able to handle the sudden or continuous heavy loads, leading to premature failure. This not only disrupts the operation of the machinery but also poses significant safety hazards to workers and the surrounding environment.

Tooth Surface Wear Resistance and Safety Factor

Secondly, the wear resistance of the gear tooth surface is another important factor influenced by the safety factor. As the gears rotate and mesh with each other, the tooth surfaces are subject to friction, which causes wear over time. A higher safety factor is often associated with better material quality and more robust manufacturing processes, resulting in tooth surfaces with enhanced wear resistance. Conversely, a low safety factor may mean the use of inferior materials or inadequate processing, leading to rapid tooth surface wear. This wear can reduce the gear's precision, cause vibrations and noise, and even result in jamming, which further shortens the service life of the entire slew drive system.

Impact Resistance and Safety Factor

Thirdly, in many working environments, spur gear slew drives may be exposed to sudden impact loads or vibrations. These can come from factors such as uneven terrain, sudden stops or starts of machinery, or external collisions. A higher safety factor enhances the gear's impact resistance, allowing it to absorb and withstand these unexpected forces. Gears with a low safety factor are more likely to suffer from tooth chipping, cracking, or other forms of damage under such impact, which can lead to immediate failure or gradual degradation of performance over time.

Characteristics of Spur Gear Slew Drive

Spur Gear Slew Drive has several distinct characteristics. One of its main features is the simplicity of its spur gear design, which makes manufacturing and maintenance relatively easy compared to other types of gears with more complex tooth profiles. This simplicity also contributes to lower production costs in some cases. Additionally, spur gears provide efficient power transmission with minimal slippage when properly aligned, ensuring that a high percentage of the input torque is transferred to the output. They also offer good rotational accuracy, which is crucial for applications requiring precise positioning, such as in automated manufacturing equipment. Moreover, Spur Gear Slew Drives are capable of handling both high torque and moderate speeds, making them versatile for a wide range of industrial uses.

Applications of Spur Gear Slew Drive

Spur Gear Slew Drives find applications in various industries. In the construction industry, they are used in cranes, excavators, and concrete pumps to enable the rotation of booms and other components. This allows for precise positioning of heavy materials, improving work efficiency on construction sites. In the renewable energy sector, they are employed in wind turbines to rotate the nacelle and blades, ensuring optimal alignment with the wind direction for maximum energy generation. Solar tracking systems also utilize these slew drives to adjust the angle of solar panels, maximizing sunlight absorption. In the material handling industry, they are integrated into conveyor systems, rotary tables, and lifting equipment to facilitate the movement and positioning of goods. Furthermore, they are used in medical equipment, such as CT scanners and surgical robots, where precise rotational movements are essential for accurate diagnostics and procedures.

Factors Influencing the Price of Spur Gear Slew Drive

The price of Spur Gear Slew Drive is influenced by several factors. Material quality is a significant factor; gears made from high - strength alloys, such as alloy steels, which offer better durability and performance, tend to be more expensive than those made from standard carbon steels. The manufacturing process also plays a role. Advanced manufacturing techniques, such as precision forging, heat treatment, and CNC machining, which ensure higher accuracy and quality, can increase production costs, thereby raising the price of the final product. The size and specifications of the slew drive are another important factor. Larger drives with higher torque capacities and speed ranges require more materials and more complex manufacturing processes, leading to higher prices. Brand reputation and market demand also affect the price. Well - known brands with a history of producing reliable products may charge a premium. Additionally, fluctuations in market supply and demand can cause price variations; when demand is high and supply is limited, prices tend to rise, and vice versa.

Supplier of Spur Gear Slew Drives

LYRADRIVE is a reputable supplier of Spur Gear Slew Drives, offering high - quality products designed to meet the diverse needs of various industries. With a focus on precision engineering and strict quality control, LYRADRIVE ensures that its slew drives deliver reliable performance, durability, and efficiency. The company provides a range of specifications to cater to different applications, backed by professional technical support and responsive customer service, making it a trusted choice for customers seeking Spur Gear Slew Drives.