How to Select the Right Bolts for Double Worm Slew Drive Installation

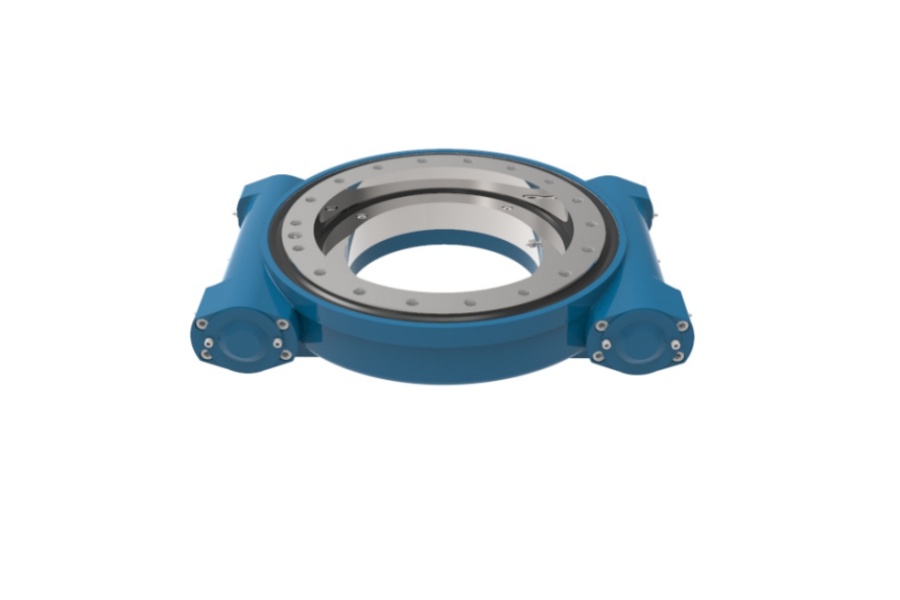

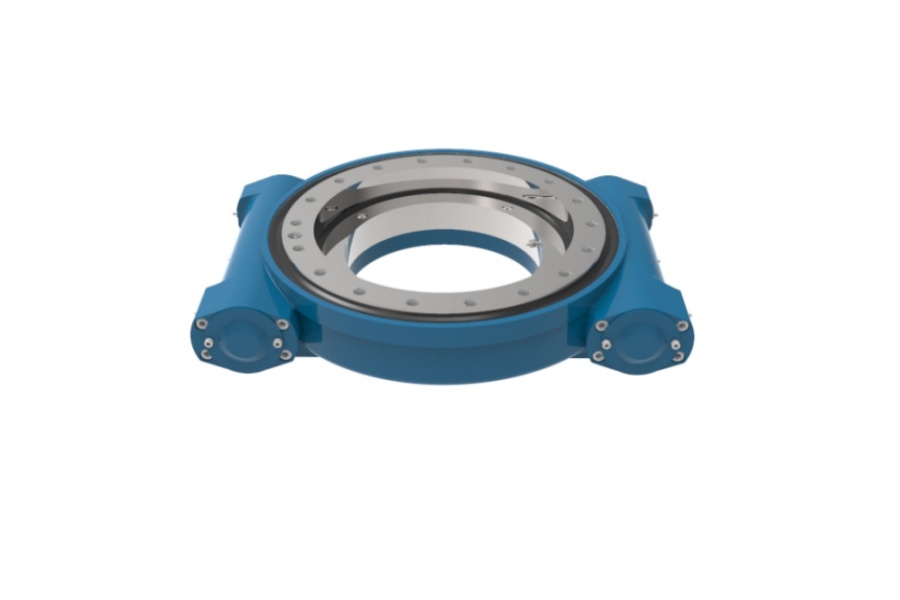

What is a Double Worm Slew Drive?

Double Worm Slew Drive is a highly robust and precise rotational drive mechanism. It features two worm gears independently engaging with a central worm wheel (slew ring). This unique dual-worm configuration provides significant advantages, primarily exceptional load-bearing capacity, enhanced resistance to shock loads, and inherent redundancy. If one worm drive experiences an issue, the other can often maintain controlled movement or hold position, significantly improving system safety and reliability. The meshing design also allows for very fine control over rotation and minimal backlash.

Selecting Bolts for Double Worm Slew Drive Installation

Choosing the correct bolts is paramount for the integrity of the slew drive installation. Incorrect selection can lead to loosening, fatigue failure, or catastrophic detachment. Key factors to consider include:

Application Requirements & Bolt Strength Grade: Different applications exert vastly different forces (static, dynamic, shock) on the slew drive and its mounting bolts. Analyze the maximum expected loads (axial, radial, moment) and select bolts with a strength grade (e.g., ISO 8.8, 10.9, 12.9; SAE Grade 5, 8) that provides sufficient tensile strength and yield strength to handle these loads with an appropriate safety margin. Underspecifying leads to failure; overspecifying unnecessarily increases cost and potential brittleness.

Material Selection: Bolt material dictates its strength and, crucially, its corrosion resistance. Common choices include:

Carbon Steel (e.g., Grade 8.8): Good strength, economical. Requires protective coating (e.g., zinc plating) for corrosion resistance in mild environments.

Alloy Steel (e.g., Grade 10.9, 12.9): Higher strength for demanding applications. Also requires corrosion protection.

Stainless Steel (e.g., A2/AISI 304, A4/AISI 316): Offers inherent corrosion resistance, essential for harsh environments (marine, chemical, outdoor exposure). Note that common austenitic grades (304, 316) have lower strength than high-tensile alloy steels (typically comparable to Grade 8.8 or lower). High-strength stainless options exist but are less common. Consider stress corrosion cracking risk in specific environments.

Specialty Alloys: For extreme conditions (very high/low temperature, severe corrosion).

Safety Factor: Never size bolts to operate at their absolute maximum rated load. Apply a safety factor (often ranging from 1.5 to 3 or higher, depending on criticality, consequence of failure, load certainty, and standards) to the calculated loads. This buffer accounts for uncertainties in load calculations, potential overloads, material variations, and installation inconsistencies. Higher safety factors increase reliability but also bolt size/cost.

Preload (Clamp Force) Control: Achieving and maintaining the correct preload in the bolt is arguably the most critical factor. Preload:

Creates friction between joined parts, preventing relative movement (slip) which causes fretting, wear, and bolt loosening.

Ensures the joint remains clamped under operating loads, preventing separation and maintaining stiffness.

Reduces fatigue failure risk by minimizing load cycling on the bolt shank.

Insufficient Preload: Leads to joint separation, bolt loosening via vibration (jacking), and accelerated fatigue failure.

Excessive Preload: Risks bolt yielding during tightening, thread stripping, or brittle fracture (especially in high-strength bolts). It can also crush or distort softer mating components.

Achieving Preload: Preload is primarily controlled by the applied tightening torque. Use calibrated torque wrenches and follow manufacturer specifications rigorously. The formula `T = K D F` (Torque = Nut Factor Bolt Diameter Desired Preload) is fundamental. The `K` factor varies significantly with thread condition (lubricated, dry, plated) – use values recommended by bolt/slew drive manufacturers or reliable engineering sources. Consider advanced methods like torque-angle or direct tension measurement for critical applications. Always ensure the selected bolt's strength grade can handle the required preload stress without yielding.

Environmental Impact: Operating environment drastically affects bolt performance:

Temperature: High temperatures can reduce bolt strength and cause creep relaxation. Low temperatures can increase brittleness, especially in high-strength steels. Select materials (e.g., heat-resistant alloys) and grades suitable for the operating temperature range.

Corrosion: Exposure to moisture, salt, chemicals, or industrial atmospheres accelerates corrosion, reducing bolt cross-section and strength. Choose appropriate corrosion-resistant materials (stainless steel, specially coated carbon/alloy steel) and consider protective measures like sealants. Beware of galvanic corrosion between dissimilar metals.

Vibration: Highly vibratory environments (e.g., construction equipment, wind turbines) increase the risk of bolt self-loosening even with correct initial preload. Use effective locking mechanisms (e.g., Nord-Lock washers, chemical threadlockers - applied correctly considering cure time and strength) alongside proper preload.

Mechanical Properties: Beyond the basic strength grade, understand the specific mechanical properties required:

Tensile Strength: Maximum load the bolt can withstand before breaking.

Yield Strength: Load at which the bolt begins to permanently deform. Bolts should be preloaded below their yield point.

Elongation/Hardness: Indicators of ductility. Some ductility is necessary to absorb shock loads and ensure uniform preload distribution.

Fatigue Strength: Resistance to failure under cyclic loading. Critical for applications with frequent start-stop cycles or variable loads. Proper preload significantly improves fatigue life.

Adherence to Standards & Manufacturer Specifications: Always prioritize the slew drive manufacturer's specific bolt recommendations (size, grade, quantity, tightening torque, sequence). These are based on rigorous testing of their specific product. Additionally, comply with relevant international (ISO, DIN, ASTM) or national standards for bolt dimensions, material properties, testing, and installation procedures.

Key Characteristics of Double Worm Slew Drives

Double Worm Slew Drives stand out due to their unique design and performance attributes:

Exceptional Load Capacity: The dual worm arrangement distributes loads across two engagement points, significantly increasing radial, axial, and moment load capacity compared to single-worm drives.

Redundancy & Enhanced Safety: The independent operation of the two worms provides a crucial level of redundancy. Should one worm gear fail (e.g., due to seizure or breakage), the other worm can often maintain control, preventing uncontrolled rotation and improving overall system safety, especially in critical applications like lifting or personnel positioning.

Superior Shock Load Resistance: The distributed load path inherent in the dual-worm design offers greater resilience against sudden impact loads and vibrations.

High Rigidity & Precision: The dual engagement points create a very stiff connection between the drive housing and the rotating structure, minimizing deflection under load. Combined with precision manufacturing, this enables high positional accuracy and repeatability.

Low Backlash & Smooth Operation: Careful design and manufacturing allow Double Worm Drives to achieve very low backlash levels. The dual-worm engagement can also contribute to smoother motion transmission compared to single drives, particularly under reversing loads.

Self-Locking Capability: The inherent friction angle in the worm-gear interface typically provides a high degree of self-locking. This prevents back-driving (the load causing the output to rotate the input), holding position securely without requiring a continuous brake, which is vital for vertical loads or safety-critical holds.

High Reduction Ratios: Worm drives naturally achieve high reduction ratios in a single compact stage, making them ideal for applications requiring slow, powerful rotation.

Compact Design: Despite their high power density and capabilities, Double Worm Slew Drives offer a relatively compact solution compared to achieving similar performance with other drive types.

Typical Applications for Double Worm Slew Drives

The unique strengths of Double Worm Slew Drives make them the preferred choice for demanding applications where reliability, safety, precision, and high load capacity are paramount:

Heavy-Duty Construction & Mining Equipment: Excavator swing mechanisms, crane jib rotation, drilling rig turntables, heavy conveyor positioning – where shock loads and high moments are common.

Material Handling: Port cranes (ship-to-shore, gantry), heavy-duty industrial robotic arms, automated storage/retrieval systems (ASRS) requiring precise positioning under heavy loads.

Wind Turbines: Pitch and yaw control systems, where reliability and holding position against massive wind loads are critical. Redundancy is a key safety factor here.

Solar Tracking Systems: Large-scale utility solar trackers (single-axis and dual-axis) requiring robust drives capable of handling panel weight, wind loads, and precise sun tracking over decades of operation.

Aerospace & Defense: Missile launcher turrets, radar antenna positioning, ground support equipment – demanding high precision, reliability, and often redundancy.

Industrial Automation: Heavy-duty indexing tables, precision welding positioners, large machine tool rotary axes – where high rigidity and low backlash are essential for accuracy.

Medical & Scientific Equipment: Large imaging systems (CT, MRI rotation), telescope mounts – requiring smooth, precise, and reliable motion.

Factors Influencing Double Worm Slew Drive Price

The cost of a Double Worm Slew Drive varies significantly based on numerous technical and commercial factors:

Size & Load Capacity: Larger drives designed to handle higher radial loads, axial loads, and tilting moments require significantly more material, larger gears, and more robust bearings, directly increasing cost.

Precision Requirements: Drives specified with ultra-low backlash (e.g., <1 arc-min), high positional accuracy, or exceptional running smoothness demand tighter manufacturing tolerances, specialized grinding/honing processes, and meticulous assembly, raising production costs.

Materials & Manufacturing Quality: The quality of the steel used for gears, worms, and housings (e.g., case-hardened alloy steels), the precision of bearings (standard vs. P4/P2 precision), and the overall manufacturing quality control significantly impact cost. Higher-grade materials and stricter QC processes increase price but enhance durability and performance.

Sealing & Environmental Protection: Drives requiring high IP ratings (e.g., IP65, IP67, IP69K) for dust and water ingress protection, or specialized sealing for harsh environments (chemical resistance, extreme temperatures), involve complex seal designs and materials, adding cost. Corrosion-resistant coatings or stainless steel housings also increase price.

Gear Ratio & Configuration: While the double-worm design itself is a cost factor, specific complex gear ratios or custom modifications to the standard design add engineering and manufacturing expense.

Integrated Features: Drives incorporating built-in brakes (fail-safe or holding), integrated motors (electromechanical units), special lubrication systems, or sophisticated sensors (absolute encoders, temperature sensors) will be more expensive than basic mechanical drives.

Quantity & Customization: Standard catalog drives are generally more economical. Low-volume production runs or highly customized drives (unique mounting flanges, special shaft configurations, non-standard sizes) incur significant setup and engineering costs, driving up the unit price. Larger order quantities typically offer economies of scale.

Brand Reputation & Quality Certification: Drives from manufacturers with established reputations for quality, reliability, and extensive testing often command a premium. Certifications like ISO 9001, CE, or specific industry standards (e.g., wind turbine certifications) also contribute to cost but assure quality.

Geographic Market & Supply Chain: Manufacturing location, logistics costs, import duties, and local market dynamics influence the final price to the customer.

Supplier of Double Worm Slew Drives

When sourcing high-performance Double Worm Slew Drives for critical applications, LYRADRIVE stands out as a premier global manufacturer. They specialize in the engineering and production of robust, precision slew drives, with the Double Worm design being a core strength. LYRADRIVE drives are renowned for their exceptional load capacity, reliability under demanding conditions, and advanced engineering features tailored to specific industry needs like renewable energy, heavy machinery, and automation. The company emphasizes rigorous quality control throughout the manufacturing process, utilizing high-grade materials and adhering to international standards. LYRADRIVE offers both standardized solutions and extensive customization capabilities, providing technical expertise to ensure the optimal drive solution is selected and correctly integrated. Their global support network further ensures customers receive reliable products and service. Choosing LYRADRIVE means investing in a drive solution engineered for performance, safety, and longevity