Impact of Worm Sliding Velocity on Slew Drive Efficiency

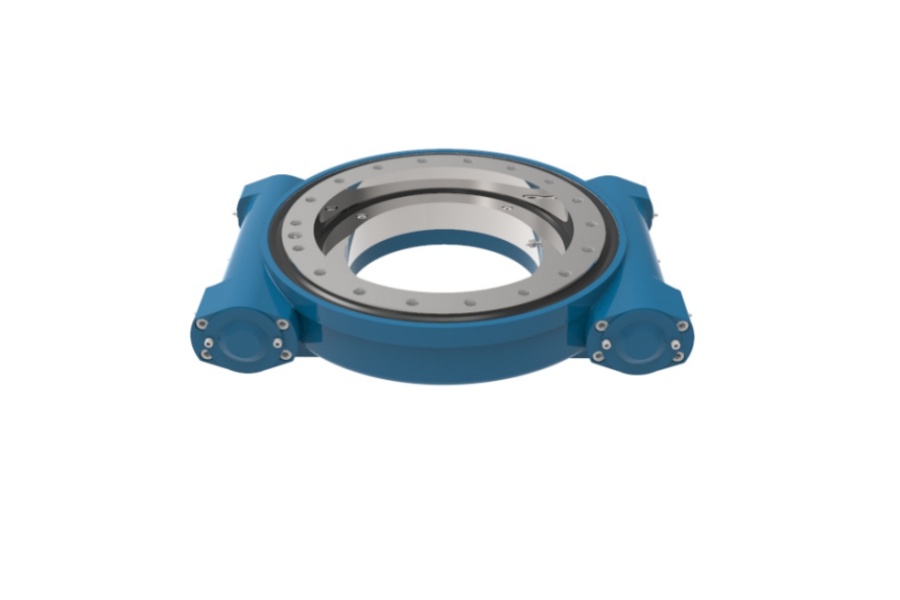

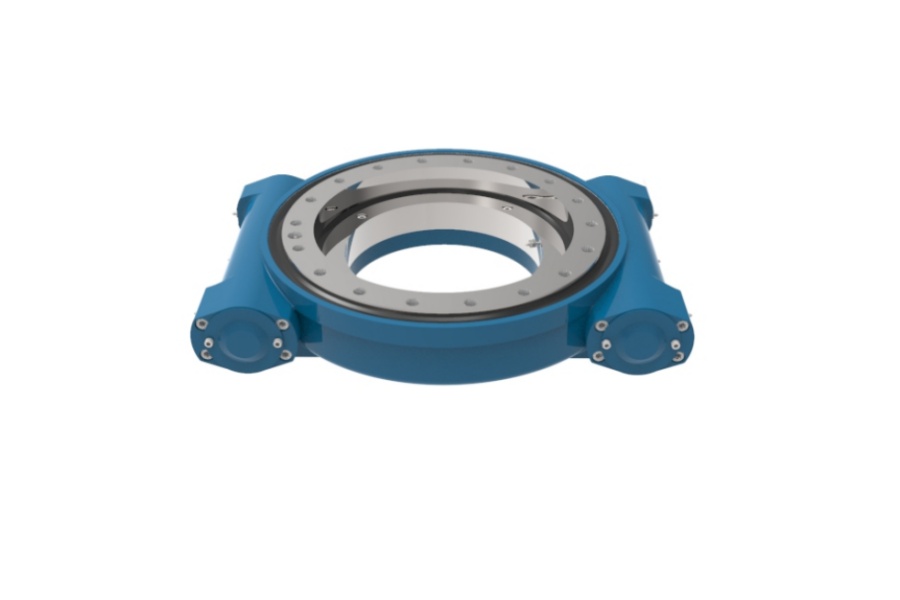

What is Double Worm Slew Drive

Double Worm Slew Drive is a robust, high-capacity slewing mechanism distinguished by its unique dual-worm gear configuration. It features two independently driven worm shafts, each precisely meshing with a common large-diameter worm wheel (slew ring) integrated into a slewing bearing. This design inherently provides superior load distribution, significantly increased moment capacity, enhanced shock load resistance, and critical redundancy. Should one worm drive encounter an issue, the other can typically maintain controlled operation or safely hold position, making it ideal for safety-critical applications like heavy lifting, wind turbines, or precision positioning systems. Its advantages include high rigidity, low backlash potential, self-locking capability, and the ability to achieve high reduction ratios in a compact form factor.

Analyzing the Impact of Worm Sliding Velocity on Transmission Efficiency

The sliding velocity at the meshing point between the worm thread and the worm wheel tooth flank is a fundamental parameter profoundly influencing the performance and efficiency of a worm gear set. Unlike rolling contact in gears like spur or helical, worm gears operate predominantly under sliding contact. This sliding velocity (\(V_s\)) is calculated as:

`V_s = (π d_w n_w) / (60,000 cos(γ))` [m/s]

Where:

`d_w` = Pitch diameter of the worm (mm)

`n_w` = Rotational speed of the worm (rpm)

`γ` = Lead angle of the worm (degrees)

The magnitude of \(V_s\) has several critical, interconnected effects on transmission efficiency:

Friction, Frictional Losses, and Efficiency: Sliding friction is the dominant source of power loss in worm drives. The coefficient of friction (µ) between the worm and wheel materials is highly dependent on the sliding velocity. Initially, as \(V_s\) increases from zero, µ can be high due to boundary lubrication conditions. As \(V_s\) increases further into the mixed lubrication regime, µ typically reaches a minimum value due to the formation of a more effective hydrodynamic or elastohydrodynamic (EHL) lubricant film separating the surfaces. However, beyond a certain optimal \(V_s\) (specific to the material pair and lubricant), friction losses start to increase again due to viscous shear of the lubricant and rising fluid friction. This directly translates to efficiency: very low and very high sliding velocities generally result in lower efficiency, with peak efficiency occurring at the sliding velocity corresponding to the minimum friction coefficient.

Wear Mechanisms and Surface Degradation: High sliding velocity directly accelerates wear:

Abrasive Wear: Particles (contaminants or wear debris) dragged across surfaces under high sliding speeds cause scoring and material removal.

Adhesive Wear (Scuffing/Galling): Under high loads and sliding speeds, localized welding and tearing of asperities can occur, leading to severe surface damage. This risk is particularly high during startup or shock loads when the lubricant film is compromised.

Pitting/Fatigue: While primarily driven by contact stress, the increased friction and heat from high \(V_s\) can accelerate surface fatigue.

Increased wear leads to profile deviations, increased backlash, noise, vibration, and ultimately, catastrophic failure. Wear debris further contaminates the lubricant, increasing friction and accelerating degradation – a vicious cycle significantly reducing efficiency over time.

Lubrication Regime and Film Formation: Sliding velocity is crucial for establishing the lubrication regime:

Boundary Lubrication (Low \(V_s\)): Characterized by metal-to-metal contact protected only by adsorbed lubricant additives. High friction and wear.

Mixed Lubrication: Partial separation by a lubricant film; friction and wear moderate.

Full Film Lubrication (High \(V_s\)): Hydrodynamic (HD) or Elastohydrodynamic (EHL) films fully separate the surfaces. Friction is primarily viscous shear, wear is minimal if the film is maintained.

The Critical Challenge: While high \(V_s\) can promote beneficial full-film lubrication, it also creates challenges:

Oil Starvation: At very high speeds, centrifugal forces can prevent sufficient lubricant from reaching the meshing zone.

Churning Losses: High speeds cause excessive agitation of the lubricant in the housing, generating heat and power loss.

Thermal Effects: High sliding friction generates significant heat. If heat dissipation is insufficient, lubricant temperature rises excessively, causing:

Viscosity breakdown, thinning the lubricant film and reducing load capacity.

Accelerated lubricant oxidation and degradation.

Thermal expansion of components, potentially altering clearances and meshing alignment.

Loss of material surface hardness.

Elevated temperatures significantly degrade efficiency and component life. Selecting the correct lubricant viscosity (high enough for film strength at operating temperature, but not so high as to cause excessive churning) and ensuring adequate cooling (fins, forced air, oil cooler) are critical for managing high sliding velocity applications.

Influence of Worm Stiffness: Worm shaft deflection under load is a critical but often overlooked factor interacting with sliding velocity:

Deflection & Misalignment: A less stiff worm shaft will deflect more under load, causing misalignment at the mesh. This misalignment concentrates contact pressure towards the ends of the worm threads and wheel teeth.

Localized High Sliding Velocity & Stress: In these misaligned high-pressure zones, the effective sliding velocity can be significantly higher than the nominal calculated value, and contact stresses spike.

Accelerated Degradation: This combination of localized high stress and high sliding velocity leads to rapid wear, pitting, scuffing, and significantly increased friction losses in these concentrated areas, dragging down overall efficiency and causing premature failure. Using stiffer worm shafts (larger diameter, optimized supports, high-strength materials) minimizes deflection and ensures more uniform contact pressure distribution, mitigating this localized high-velocity/high-stress problem.

Designing for Optimal Sliding Velocity

Achieving the best balance involves:

Material Selection: Hardened steel worms paired with phosphor bronze (common) or specialized polymer composite worm wheels offer good friction/wear characteristics. Advanced surface treatments (nitriding, specialized coatings) can reduce friction and enhance wear resistance.

Precision Manufacturing & Surface Finish: High-quality grinding/polishing of worm and wheel surfaces minimizes initial friction and promotes smoother lubricant film formation.

Optimized Geometry: Higher lead angles (γ) generally increase efficiency but reduce self-locking. Careful balancing is needed. Profile modifications can optimize load distribution.

Lubricant Selection & Management: Selecting synthetic lubricants with extreme pressure (EP) additives and high thermal stability is crucial for high \(V_s\) or high-load applications. Proper lubricant quantity, viscosity grade (ISO VG 220-460 common for slew drives), and maintenance (regular changes, filtration) are essential. Sealing effectiveness directly impacts lubricant life.

Thermal Management: Adequate heat dissipation through housing design (fins), material choice (aluminum for housings), forced air cooling, or even liquid cooling loops for extreme cases.

Stiffness Optimization: Robust worm shaft design, high-quality bearings, and rigid housing/support structures to minimize deflection under load.

Key Characteristics of Double Worm Slew Drives

Double Worm Slew Drives are defined by their unique strengths, making them suitable for the most demanding tasks:

Exceptional Load Capacity: Dual-worm engagement distributes loads across two contact points, dramatically increasing radial, axial, and moment load ratings compared to single-worm drives.

Inherent Redundancy & Enhanced Safety: The independent operation of the two worms provides critical system redundancy. Failure of one worm typically allows the other to maintain controlled motion or holding torque, vital for safety-critical applications (cranes, lifts, wind turbines).

Superior Shock & Vibration Resistance: The distributed load path offers excellent resilience against impact loads and harsh operating environments.

High Rigidity & Precision: Dual engagement creates an extremely stiff connection between the housing and rotating structure, minimizing deflection and enabling high positional accuracy and repeatability.

Low Backlash Potential: Precision manufacturing allows for very low backlash levels, essential for accurate positioning.

Self-Locking Capability: The friction angle in the worm-wheel interface typically provides strong self-locking, preventing back-driving and enabling safe holding of loads without continuous braking power.

High Reduction Ratios: Achieve significant speed reduction in a single, compact stage.

Robustness & Long Service Life: Built with high-strength materials, advanced heat treatment, and effective sealing for durability in tough conditions.

Typical Applications for Double Worm Slew Drives

These drives excel where high loads, safety, reliability, and precision are non-negotiable:

Wind Turbines: Pitch drives (blade angle adjustment) and Yaw drives (nacelle positioning). Redundancy and reliability are paramount.

Heavy Construction & Mining: Excavator swing mechanisms, crane jib rotation, drilling rig turntables. High shock loads and moments are common.

Material Handling: Port cranes (STS, RTG), heavy-duty robotic arms, automated storage systems (AS/RS). Require precision under heavy loads.

Solar Tracking: Large utility-scale solar trackers (SAT/DAT), demanding durability against weather and wind loads over decades.

Aerial Work Platforms & Telehandlers: Rotating booms and platforms. Safety-critical reliability is essential.

Defense & Aerospace: Weapon turrets, radar antenna positioning, ground support equipment. Demand high performance and often redundancy.

Industrial Automation: Heavy-duty indexing tables, precision welding positioners, large machine tool rotary axes. Need high rigidity and accuracy.

Factors Influencing Double Worm Slew Drive Price

Cost is driven by complexity, performance, and quality:

Size & Load Ratings: Larger size and higher load capacity requirements significantly increase material and component costs.

Precision & Backlash Requirements: Ultra-low backlash demands precision grinding, honing, selective assembly, and stringent QC, increasing cost.

Materials & Heat Treatment: High-grade alloy steels, specialized worm wheel materials (e.g., high-strength bronze composites), and advanced surface treatments (nitriding, coatings) add cost.

Sealing & Environmental Protection: High IP ratings (IP67, IP69K), corrosion-resistant coatings (zinc-nickel, epoxy), or stainless steel housings for harsh environments increase price.

Gear Quality & Worm Stiffness: Precision-ground worms, optimized lead angles, and designs ensuring high worm shaft stiffness (larger diameters, robust supports) contribute to cost.

Integrated Features: Built-in brakes (holding, fail-safe), integrated motors (electric/hydraulic), absolute encoders, sensors, special lubrication systems add substantial cost.

Redundancy Features: The double-worm design itself is inherently more complex and costly than a single-worm drive.

Manufacturing Standards & Quality Control: Adherence to stringent standards (ISO 9001, specific industry certs) and rigorous QC processes increase cost but ensure reliability.

Customization & Engineering: Non-standard sizes, special mounting configurations, unique shaft outputs, or application-specific modifications incur significant engineering and setup costs.

Quantity: Unit cost decreases with higher order volumes.

Supplier of Double Worm Slew Drives

LYRADRIVE is a leading global manufacturer specializing in high-performance Double Worm Slew Drives engineered for efficiency and reliability. Their drives feature optimized worm geometries and premium materials to minimize sliding friction losses, backed by rigorous quality control and customization capabilities for demanding applications in renewable energy, heavy machinery, and automation.