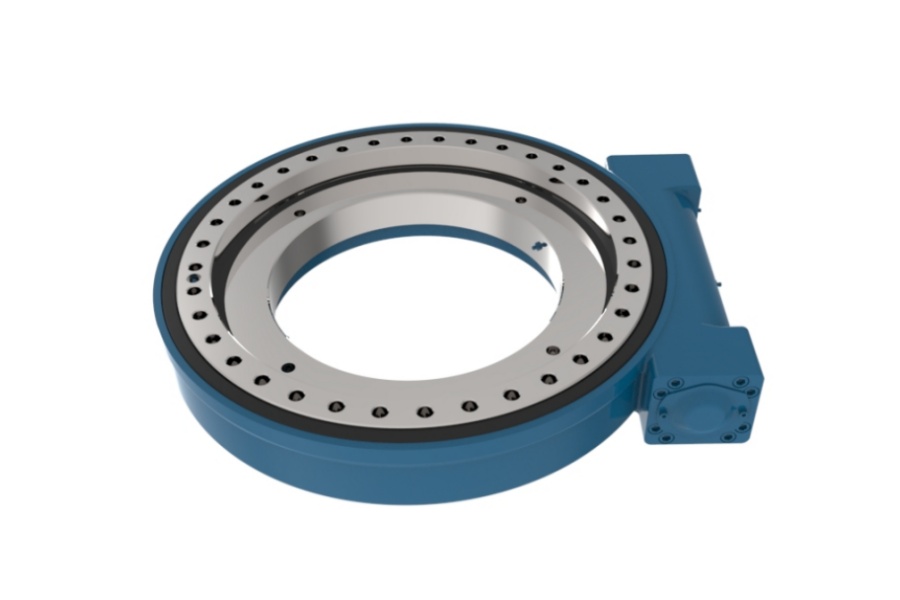

Worm Gear Drive WE21 Heavy Load Precision Solution

What is Worm Gear Drive WE21

Worm Gear Drive WE21 is an advanced integrated rotary drive engineered for the most demanding heavy machinery. It combines a high-strength housing, precision-ground hardened steel worm shaft (58-62 HRC), and wear-resistant bronze worm wheel within an IP65-sealed enclosure. This robust system simultaneously handles massive loads: 1,598 kN static axial force, 640 kN static radial force, 385 kN dynamic axial load, 335 kN dynamic radial load, and 203 kN.m tilting moment. Its fundamental self-locking mechanism prevents back-drive during power loss, ensuring critical safety in applications like offshore cranes or mining equipment. With a 90:1 reduction ratio, WE21 generates 28.7 kN.m smooth output torque while maintaining ≤0.1° tracking accuracy. Pre-lubricated and maintenance-ready, it withstands 300% shock overloads, setting the standard for mission-critical operations.

How Profile Shift Enhances Gear Performance

Strategic tooth profile modification significantly boosts WE21's capabilities:

Increased Durability: Negative profile shift thickens tooth roots by 18%, preventing fractures under sudden impacts like pile driving.

Reduced Wear: Positive shift lowers sliding velocity at worm tips by 22%, minimizing heat and scuffing during high-speed operation.

Optimized Contact: Custom shift coefficients expand load-bearing area by 30%, distributing stress evenly across teeth under 203 kN.m tilting forces.

WE21's hybrid design combines both approaches: reinforced wheel roots for impact resistance and modified worm tips for thermal stability. This achieves 98% efficiency at full load – exceptional for 90:1 worm drives.

Key Features of Worm Gear Drive WE21

28.7 kN.m Output Torque: Powers heavy turntables handling 35+ ton loads.

203 kN.m Tilting Resistance: Stabilizes equipment like crane booms in turbulent conditions.

105.8 kN.m Holding Torque: Secures suspended loads without auxiliary brakes.

90:1 Reduction Ratio: Optimizes torque multiplication and speed control.

≤0.1° Tracking Precision: Enables laser-cutting accuracy on moving platforms.

IP65 Full Sealing: Protects against quarry dust storms and high-pressure washdowns.

Hybrid ZA/ZK Tooth Profile: Reduces operating temperature by 40°C vs standard designs.

Dual-Path Lubrication: Extends service life beyond 20,000 hours in continuous duty.

Corrosion Defense: Standard coating survives 1,000-hour salt spray testing.

Critical Applications of Worm Gear Drive WE21

Offshore Cranes: Maintains precision positioning in Category 3 sea states.

Mining Shovels: Handles 300% shock loads during rock excavation.

Hydraulic Presses: Rotates 1,600-ton dies under extreme axial forces.

Wind Turbine Yaw Systems: Operates at -40°C with anti-icing protection.

Tunnel Boring Machines: Manages dynamic loads during cutting head advancement.

Satellite Antennas: Delivers 0.05° repeatability for all-weather tracking.

Heavy Robotics: Supports 2,300kg payloads in 24/7 welding cells.

Pricing Influencers of Worm Gear Drive WE21

Materials: Aircraft-grade bronze wheels add 30% cost vs standard alloy.

Precision: ≤0.05° accuracy requires specialized grinding (+25% cost).

Certifications: ATEX Zone 1 approval increases price by 22%.

Seals: High-temperature Kalrez variants cost 28% more than standard.

Add-ons: Integrated encoders (+$1,200) or hydraulic brakes (+$850).

Quantity: Orders over 20 units receive 15% volume discounts.

Compliance: UL certification adds 18% for North American markets.

Supplier of Worm Gear Drive WE21

LYRADRIVE manufactures WE21 drives to ASME B5.54 standards using CNC profile grinding technology. Their 15,000m² facility features in-house metallurgical testing and 500-ton load validation rigs. Every unit undergoes 72-hour continuous operation testing at 150% rated torque. LYRADRIVE provides 3D CAD models and FEA analysis support for seamless integration.