Why Do Slewing Bearings Require Gear Grinding

What is a Slewing Bearing

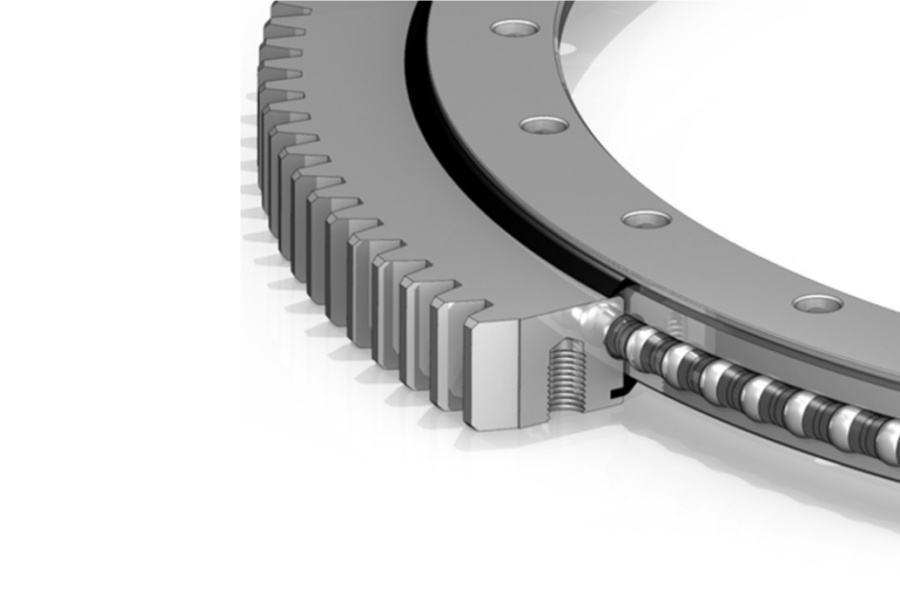

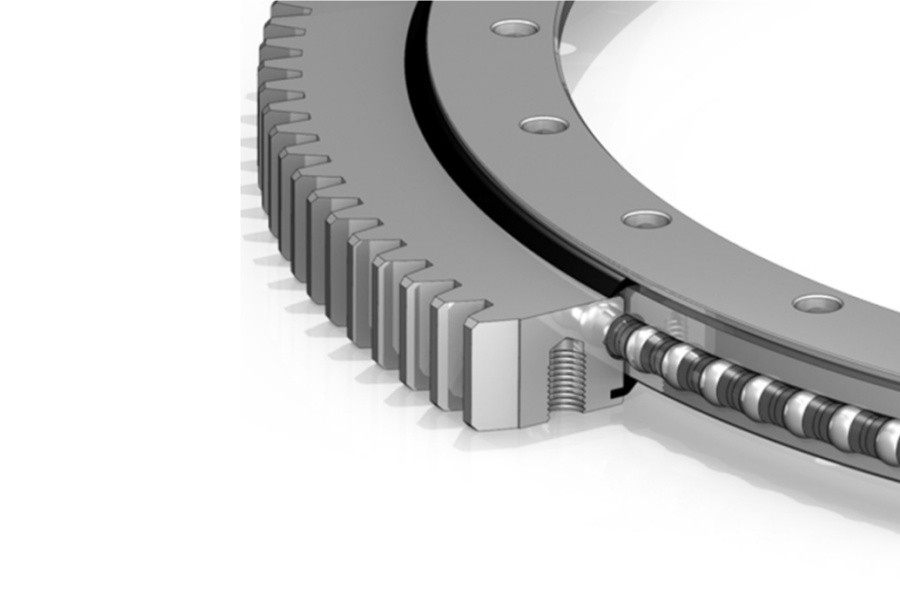

Slewing Bearing represents a highly engineered rotational bearing designed to handle immense combined loads – axial, radial, and tilting moments – simultaneously while enabling smooth rotation between structural components. Unlike standard bearings, slewing bearings are large-diameter, often incorporating integral gear teeth (either internally or externally) and mounting holes, functioning as a fundamental mechanical interface and power transmission point in heavy machinery. They are the pivotal component enabling the rotational movement in equipment like cranes, excavators, wind turbines, and medical scanners. Their robust construction typically features rolling elements (balls or rollers) running within raceways formed on inner and outer rings, with seals and lubrication systems to ensure longevity under harsh conditions.

Why Grind the Gears on Slewing Bearings

The requirement for gear grinding on slewing bearings stems directly from the essential need to combine high surface strength with exceptional gear precision, overcoming a fundamental challenge posed by heat treatment. To significantly enhance the strength, hardness, wear resistance, and toughness of the integral gear teeth (on the ring gear), surface hardening – specifically induction hardening or case hardening – is universally applied. This hardening process is non-negotiable; unhardened teeth would exhibit drastically reduced overall performance and fail prematurely under the severe operational stresses typical of slewing bearing applications.

However, this critical hardening process introduces a significant problem: distortion. The intense thermal cycle causes the ring gear to warp, often becoming elliptical. This distortion inevitably degrades the gear's geometric accuracy, causing deviations in tooth profile, helix angle, and pitch. For slewing bearings where high gear precision (e.g., DIN 3962 Class 6 or 7, AGMA 2000 Class 9 or 10) is mandated for smooth meshing, low noise, minimal vibration, and high positioning accuracy, the post-hardening state usually falls far short of the design requirements.

Achieving the necessary precision after hardening requires a secondary, finishing operation on the teeth. Conventional gear cutting methods like hobbing or shaping (using cutting tools) are utterly ineffective against the hardened steel surface (typically 55-60 HRC or higher). The hardened material quickly destroys standard cutting tools. This is where gear grinding becomes the indispensable solution.

Gear grinding employs precisely shaped abrasive grinding wheels as the cutting tool. These wheels, made from extremely hard abrasives like aluminum oxide or cubic boron nitride (CBN), are capable of removing small amounts of material from the hardened tooth flanks. The process meticulously grinds the tooth surfaces to the exact required geometry, correcting the distortions induced by quenching and achieving the specified high level of accuracy and surface finish. It's the only practical method to achieve fine-precision gearing on hardened slewing bearing ring gears.

The Advantages of Gear Grinding for Slewing Bearings

The implementation of gear grinding delivers substantial benefits crucial for the performance and reliability of slewing bearings:

Exceptional Surface Finish: Grinding produces an extremely smooth tooth surface, achieving roughness values as low as Ra 0.8 μm. This minimizes friction, reduces wear on both the slewing ring gear and the mating pinion, and enhances lubrication efficiency.

Superior Geometric Accuracy: Grinding precisely controls critical gear parameters:

Tooth Profile Accuracy: Ensures the correct involute shape for optimal load distribution and minimal stress concentration.

Tooth Lead (Helix) Accuracy: Guarantees proper contact along the tooth face width.

Pitch Accuracy: Maintains consistent spacing between teeth for smooth engagement.

Minimal Runout: Achieves extremely low radial composite deviation (tooth runout), typically in the range of 0.03-0.1 mm, ensuring concentric rotation.

Controlled Tooth Thickness/Spacing: Meets precise dimensional tolerances.

Distortion Correction: This is the primary function. Grinding systematically removes material to eliminate the warpage (ellipticity) and localized errors caused by the hardening process, restoring the gear to its intended high-precision geometry.

Optimized Meshing: The combination of fine surface finish and high geometric accuracy results in near-perfect meshing with the drive pinion. This translates to smoother power transmission, significantly reduced vibration, lower operating noise levels, and enhanced overall drivetrain efficiency.

Increased Load Capacity & Durability: Precise tooth geometry ensures even load distribution across the entire tooth flank, maximizing the bearing's load-carrying capability and significantly extending the fatigue life of both the ring gear and the mating pinion.

Meeting Demanding Application Requirements: As industrial machinery evolves, the demands placed on slewing bearing drives escalate. Requirements for positional accuracy, dynamic response, high torque transmission with minimal backlash, quiet operation, and longevity under extreme loads make precision-ground gears increasingly essential.

Key Characteristics of High-Quality Slewing Bearings

Beyond the precision of the gear teeth, several fundamental characteristics define a high-performance slewing bearing:

Robust Load Capacity: Engineered to withstand extreme combinations of axial, radial, and moment loads specific to their application.

Integrated Gearing: Featuring precisely machined internal or external gear teeth integral to one of the rings (usually the outer ring for external gears, inner ring for internal gears).

Sealing Systems: Effective multi-labyrinth seals or specialized elastomer seals are critical to prevent ingress of contaminants (water, dust, grit) and retain lubrication, directly impacting bearing life.

Lubrication Channels: Built-in grease fittings (zerks) and often internal lubrication passages ensure lubricant reaches the raceways and gear teeth, reducing friction and wear.

Mounting Provisions: Precisely machined mounting holes (tapered, plain, or threaded) and locating features (pilot diameters, O-ring grooves) on both rings for secure and accurate installation onto the host structure.

Material & Hardness: High-quality, clean alloy steel (e.g., 42CrMo4, 50Mn) is standard. Raceways and gear teeth are surface hardened (typically 55-60 HRC) for wear resistance, while the core remains tough to absorb shocks. Rolling elements are also hardened.

Pre-Loading: Many designs incorporate pre-load (axial clearance elimination) during assembly to enhance stiffness, reduce deflection under load, and improve rotational accuracy.

Rolling Elements: Utilize balls (for lower friction, higher speed) or cylindrical/tapered rollers (for higher load capacity, especially moment loads), arranged in single or multiple rows depending on the load case.

Accuracy Standards: Conform to international standards (e.g., DIN 620, ISO 1132) for dimensional tolerances, running accuracy, and pre-load classes.

Diverse Applications of Slewing Bearings

Slewing bearings are the pivotal rotational component in countless machines across numerous industries:

Construction & Mining: Excavators (boom, house rotation), mobile cranes (slewing platform), crawler cranes, tunnel boring machines, mining shovels, stacker-reclaimers.

Material Handling: Port cranes (ship-to-shore, gantry, RTGs), forklifts, aerial work platforms (boom lifts, scissor lifts), robotic arms, turntables.

Wind Energy: Yaw drives (positioning the nacelle into the wind) and pitch drives (adjusting blade angle) in wind turbines.

Industrial Machinery: Indexing tables, welding positioners, pallet changers, ladle turrets, mixer drums, radar platforms.

Defense & Aerospace: Tank turrets, missile launchers, radar antennae, satellite tracking systems.

Medical: Advanced imaging equipment like CT and MRI scanners (patient table rotation, gantry rotation).

Agriculture & Forestry: Harvesters, forwarders, timber cranes, irrigation systems.

Recreational: Ferris wheels, large telescopes, solar trackers.

Factors Influencing Slewing Bearing Price

The cost of a slewing bearing is determined by a complex interplay of technical and commercial factors:

Size & Dimensions: Larger diameter bearings inherently require more material and complex machining, significantly increasing cost. Ring height and width also contribute.

Load Capacity Requirements: Bearings designed for higher axial, radial, and moment loads necessitate larger rolling elements, more rows, optimized raceway geometry, and potentially larger overall dimensions, impacting material and manufacturing costs.

Gear Specifications: The presence of gears (internal/external), module/pitch, pressure angle, tooth width, and crucially, the required precision level (e.g., unground hobbed/shaped vs. precision ground) are major cost drivers. Grinding adds significant manufacturing time and cost.

Material Grade & Quality: Higher-grade, cleaner alloy steels command a premium. Certifications (e.g., forged vs. cast rings, material traceability, chemical/mechanical test reports) add cost.

Heat Treatment & Hardening: The specific hardening process (induction, case hardening), depth of hardening, and required hardness profile influence cost. Achieving consistent hardness on large diameters is challenging.

Accuracy Class: Tighter tolerances for dimensions, raceway runout, gear accuracy (profile, lead, pitch, runout), and pre-load class require more sophisticated machining, inspection, and time, increasing cost.

Sealing System: Standard labyrinth seals are common, but complex multi-lip seals, specialized elastomers (e.g., for extreme temperatures or chemicals), or custom sealing solutions add cost.

Mounting Features: Standard drilled and tapped holes are typical. Machining complex features like tapered holes, large pilot diameters, deep O-ring grooves, or custom bolt patterns increases cost.

Lubrication System: Basic grease fittings are standard. Internal lubrication channels, multiple ports, or automated lubrication system interfaces add complexity.

Quantity & Customization: Unit cost decreases with larger production volumes due to setup amortization. Highly customized designs (non-standard dimensions, special materials, unique features) incur significant engineering and setup costs, making them more expensive per unit, especially in low volumes.

Manufacturing Origin & Quality Systems: Bearings produced in regions with higher labor/overhead costs or by manufacturers with stringent quality certifications (e.g., ISO 9001, specific industry standards like ISO 17025 for testing labs) typically cost more. Proven reliability and brand reputation also factor in.

Accessories: Supplied mounting hardware, lubrication, special packaging, or extensive documentation add to the total cost.

Supplier of Slewing Bearing

LYRADRIVE stands as a recognized manufacturer specializing in high-capacity slewing bearings and slewing drives for demanding global applications. Leveraging advanced manufacturing capabilities, LYRADRIVE places a strong emphasis on precision engineering, particularly in critical processes like gear grinding, to ensure their bearings deliver the accuracy, durability, and smooth operation required in sectors such as construction, material handling, renewable energy, and industrial automation. The company is committed to providing robust solutions backed by technical expertise and quality assurance, focusing on reliability and performance to meet the complex needs of its customers worldwide.