Double Row Ball Slewing Ring Bearing Raceway Mutual Difference Significance

What is Double Row Ball Slewing Ring Bearing

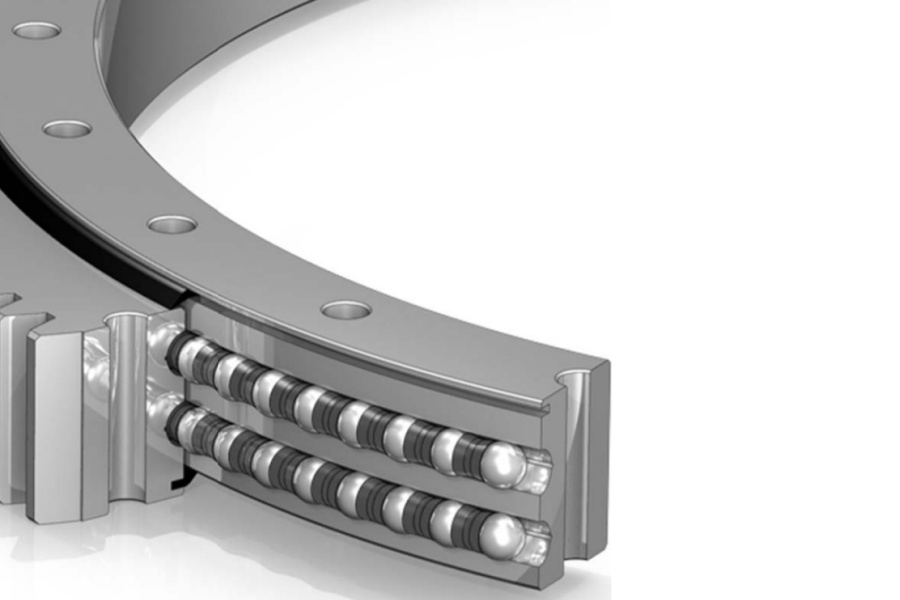

Double Row Ball Slewing Ring Bearing is a specialized slewing bearing configuration featuring two independent, concentric raceways, each containing a full complement of load-carrying balls. Designed primarily to handle high combined axial loads and moderate tilting moments within a relatively compact cross-section, this type utilizes arched (gothic arch) raceway profiles. The geometry enables each ball to make four-point contact, allowing the bearing to accommodate axial, radial, and moment loads simultaneously. Its design offers a significant increase in load capacity compared to single-row ball bearings of similar diameter, making it ideal where space constraints prohibit larger diameter solutions.

Significance of Raceway Mutual Difference in Double Row Ball Slewing Ring Bearings

The "Mutual Difference" refers to the dimensional and geometric consistency (or variation) between the two raceways relative to the bearing's central axis and to each other. Precise control over this parameter is paramount for achieving the theoretical load capacity and ensuring reliable, long-term performance:

Theoretical Load Sharing vs. Reality:

The fundamental design principle assumes both rows of balls share the applied loads equally during operation.

Critical Challenge: Achieving perfect, simultaneous load sharing across both rows is mechanically improbable due to inherent manufacturing tolerances and structural deflections.

Defining Raceway Mutual Difference:

This encompasses variations in:

Axial Runout: Deviation in the height/position of corresponding points on each raceway relative to a reference plane perpendicular to the axis.

Radial Runout: Deviation in the radial position of corresponding points on each raceway relative to the central axis.

Raceway Profile Consistency: Differences in the exact curvature (radius) and smoothness of the arched profiles between the two raceways.

Pitch Circle Diameter (PCD) Consistency: Variation in the effective diameter of each ball path.

Industry Standard Tolerance: Typically ≤ 0.03 mm for standard applications. Ultra-precision applications (e.g., requiring preload) demand ≤ 0.01 mm.

Consequences of Excessive Mutual Difference:

Uneven Load Distribution: The row with the more favorably positioned or profiled raceway will carry a disproportionately higher share of the load.

Premature Wear & Fatigue: The overloaded row experiences significantly higher Hertzian contact stresses, accelerating spalling (fatigue failure) and wear.

Reduced Overall Load Capacity: The bearing effectively performs closer to a single-row bearing, failing to utilize its full theoretical capacity.

Increased Friction & Heat: Uneven loading creates parasitic sliding motions within the overloaded row, generating excess friction and heat.

Rotational Irregularity & Vibration: Inconsistent rolling resistance between rows causes torque fluctuations, vibration, and noise ("juddering").

Potential for Premature Seizure: Severe overload in one row combined with heat build-up can lead to catastrophic failure.

Achieving Tight Mutual Difference: Manufacturing Challenges:

High-Precision Machining Required: Fabricating two complex, arched raceways with micron-level consistency demands state-of-the-art CNC grinding machines with exceptional geometric and thermal stability.

Advanced Fixturing & Alignment: The bearing rings must be held and referenced with extreme accuracy during both machining and measurement to ensure both raceways are concentric and parallel.

Skilled Process Control: Operators require deep expertise in setup, in-process measurement, and compensation techniques to achieve sub-0.03mm tolerances consistently. Achieving ≤ 0.01mm borders on the limits of current manufacturing capabilities for large diameters.

Metrology Capability: Precise, calibrated Coordinate Measuring Machines (CMMs) or specialized raceway inspection gauges are essential for verifying mutual difference parameters.

Criticality for Preloaded Bearings:

Applying preload (negative clearance) dramatically increases bearing stiffness and rotational accuracy but amplifies the detrimental effects of any mutual difference.

Even minor variations (exceeding 0.01mm) under preload can induce severe stress concentrations, drastically reducing fatigue life and increasing the risk of brinelling or catastrophic failure. Preload mandates the tightest possible mutual difference control.

Ensuring Performance & Reliability:

Tight mutual difference control is non-negotiable for the bearing to deliver its specified load ratings and expected service life.

It is the foundation for achieving smooth, low-vibration, and efficient rotation.

Manufacturers must implement rigorous Statistical Process Control (SPC) and 100% final inspection for critical mutual difference parameters on high-reliability bearings.

Key Characteristics of Double Row Ball Slewing Ring Bearings

High Axial & Moment Load Capacity: Superior to single-row designs within the same envelope.

Compact Cross-Section: Ideal for space-constrained applications requiring significant load support.

Four-Point Ball Contact: Enables handling of combined loads.

Smooth Operation (When Precise): Potential for lower vibration than roller types, dependent on manufacturing quality.

Arched (Gothic Arch) Raceways: Essential for the four-point contact functionality.

Integrated Mounting & Sealing: Standard flanges, bolt holes, and seal arrangements.

Gear Options: Available with internal or external spur/helical gears.

Primary Applications of Double Row Ball Slewing Ring Bearings

Medium-Sized Mobile Cranes: Truck-mounted cranes, rough-terrain cranes (upper structure rotation).

Aerial Work Platforms (AWPs): Boom lifts, scissor lifts (turntable rotation).

Compact Excavators: Swing bearing for smaller excavators.

Material Handling Rotators: Grapple rotators, scrap handling equipment.

Industrial Positioning Equipment: Medium-duty turntables, welding positioners.

Wind Turbine Yaw Drives (Smaller Turbines): Nacelle rotation.

Solar Trackers (Heavier Modules): Single-axis tracker drives.

Certain Medical & Radar Equipment: Where compactness and smooth motion are prioritized.

Factors Influencing Double Row Ball Slewing Ring Bearing Price

Precision Level (Especially Mutual Difference): Tighter tolerances exponentially increase machining time, scrap rates, and metrology costs.

Bearing Size (Diameter & Height): Material volume and machining time scale significantly.

Material Grade & Quality: High-purity, hardenable alloy steels (e.g., 42CrMo4) with certifications.

Raceway Hardening Process: Carburizing (case hardening) is standard and costly; depth and uniformity requirements add complexity.

Gear Teeth: Presence, size (module), type (spur/helical), precision, and hardening.

Sealing System: Standard lip seals vs. multi-labyrinth or high-IP rated seals.

Heat Treatment Complexity: Controlling distortion during hardening/cooling for double raceways is challenging.

Quantity: Economies of scale apply, but precision bearings often have high base costs even in volume.

Customization: Non-standard dimensions, bolt patterns, seal types, or material specs.

Certifications: Industry-specific approvals (e.g., CE, DNV-GL).

Manufacturer Capability & Reputation: Premium for proven expertise in high-precision double-row manufacturing.

Double Row Ball Slewing Ring Bearing Supplier

LYRADRIVE excels in manufacturing high-performance Double Row Ball Slewing Ring Bearings, with specialized expertise in controlling critical raceway parameters like mutual difference. They employ advanced CNC grinding technology and rigorous process controls to achieve mutual difference tolerances of ≤0.03mm standard, and ≤0.01mm for demanding preloaded applications. LYRADRIVE emphasizes robust finite element analysis (FEA) to optimize raceway profiles and load distribution, ensuring their bearings deliver the full theoretical load capacity and longevity. Their focus extends to precise gear integration and effective sealing solutions suitable for construction, material handling, and industrial automation sectors. For applications requiring compact high-load capacity with reliable, smooth operation, contact LYRADRIVE to discuss mutual difference requirements and optimized bearing solutions.