Slewing Bearing and Slew Drive Lubrication Purpose

What is Slew Drive and Slewing Bearing

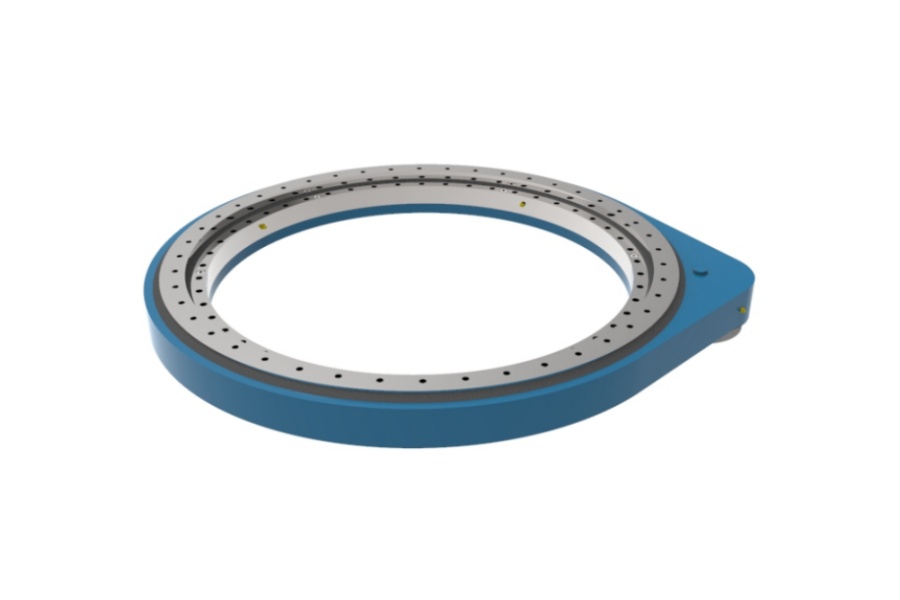

Slewing Bearing is a large-diameter rotational bearing designed to handle combined axial, radial, and tilting moment loads while enabling rotation between structures. It typically features mounting holes, sealing, and often internal or external gear teeth.

Slew Drive (or slewing drive) is a complete rotational system integrating a slewing bearing with a gear reduction mechanism (like a worm or planetary gearbox) and a drive motor (electric or hydraulic), all housed within a single unit. It functions as a compact, high-torque rotary actuator.

Why Grease Lubrication is Essential for Slewing Bearings and Slew Drives

Grease is the lifeblood of these critical components. Its absence or degradation leads directly to premature failure. The key functions are:

Friction Reduction & Wear Prevention:

Forms a protective film between rolling elements (balls/rollers) and raceways, and between meshing gear teeth (pinion and ring gear).

Minimizes direct metal-to-metal contact, drastically reducing abrasive wear, adhesive wear (scuffing), and surface fatigue (pitting/spalling).

Protection Against Corrosion:

Coats metal surfaces, acting as a barrier against moisture, oxygen, and corrosive contaminants (salts, chemicals).

Contains rust and oxidation inhibitors that chemically neutralize corrosive agents, vital for outdoor or harsh environment applications.

Contaminant Exclusion & Removal:

Acts as a physical barrier, helping seals trap external contaminants (dust, dirt, water, abrasive particles).

Suspends small ingested particles within its thickener matrix, preventing them from embedding into metal surfaces and causing wear ("lapping" effect). Regular relubrication helps flush out some contaminants.

Vibration Damping & Noise Reduction:

Absorbs and dampens vibrations generated by rolling elements, gear meshing, and operational loads.

Promotes smoother, quieter operation by cushioning impacts and reducing gear whine or rattling.

Heat Dissipation (Limited):

While not as effective as oil circulation, grease helps transfer some frictional heat away from critical contact zones (raceways, gear mesh) towards the housing, where it can dissipate.

Prevents localized overheating that can degrade grease and damage components.

Seal Lubrication & Protection:

Keeps lip seals supple, preventing drying, cracking, and loss of sealing effectiveness.

Reduces friction between seal lips and bearing rings, extending seal life.

Critical Considerations for Grease Selection and Maintenance:

Correct Grease Type: Must be specifically formulated for slow-speed, heavily loaded rolling element bearings and gears. Key properties include:

High-viscosity base oil (ISO VG 150-460 common).

Extreme Pressure (EP) additives (e.g., Sulfur-Phosphorus).

Solid lubricants (e.g., Molybdenum Disulfide, Graphite) for boundary conditions.

Thickener compatible with seals (Lithium Complex, Polyurea common).

Corrosion inhibitors, oxidation stabilizers.

Compatibility: Never mix incompatible greases (different thickeners/base oils). If changing grease, ensure compatibility or perform a thorough purge.

Relubrication Intervals: Crucial! Intervals depend on:

Operating temperature (high temp degrades grease faster).

Speed (higher speed accelerates grease breakdown).

Load severity (shock loads squeeze out grease).

Contamination level (dirty environments require more frequent greasing).

Seal effectiveness.

Follow manufacturer recommendations rigorously.

"Lubricated-for-Life" Misconception: While some units come sealed and greased, true "life" is finite. Extreme conditions, high temperatures, or extended periods necessitate eventual relubrication or grease replacement.

Relubrication After Storage: Bearings stored for extended periods (especially > 3-5 years) should be relubricated before commissioning, as grease can separate or degrade.

Adequate Quantity: Ensure grease reaches all critical contact points (raceways, gears). Under-lubrication is as harmful as over-lubrication (which can cause seal damage or churning losses).

Key Characteristics of Slewing Bearings and Slew Drives

High Load Capacity: Engineered for combined axial, radial, and moment loads.

Integrated Functionality: Slewing bearings combine load support and rotation; Slew drives add power transmission and reduction.

Robust Construction: High-strength steels, precision machining, heat treatment.

Sealing Systems: Essential for retaining grease and excluding contaminants (lip seals, labyrinth seals).

Gearing: Integral to both (slewing bearing ring gear, slew drive gearbox).

Mounting: Direct bolt-on design.

Variety: Multiple bearing types (ball/roller), drive types (worm/planetary).

Primary Applications

Construction: Excavators, cranes (slewing bearing); Solar trackers, crane jibs (slew drive).

Renewable Energy: Wind turbine yaw/pitch (both); Solar tracker drives (slew drive).

Material Handling: Stackers, ship cranes (slewing bearing); Rotators, positioning systems (slew drive).

Industrial Automation: Turntables, indexers (slewing bearing); Robotic joints, welding positioners (slew drive).

Defense/Aerospace: Radar bases, turrets (both).

Mining: Excavators, draglines (slewing bearing); Conveyor drives (slew drive).

Marine: Deck cranes (slewing bearing); Winches, thrusters (slew drive).

Factors Influencing Price

Size & Load Capacity: Larger size/higher loads = more material/complexity.

Precision & Tolerance: Tighter tolerances increase machining/QC costs.

Material & Heat Treatment: Alloy grade, hardening process (carburizing vs induction).

Gearing: Gear presence (slewing bearing), type, precision, complexity (slew drive gearbox).

Sealing: Seal type, complexity, IP rating.

Integrated Components: Motor inclusion (slew drive).

Lubrication System: Complexity (ports, auto-lube compatibility).

Customization: Non-standard designs.

Certifications: Industry-specific (CE, DNV-GL, etc.).

Quantity & Manufacturer: Volume discounts; premium for established quality.

Slewing Bearing and Slew Drive Supplier

LYRADRIVE designs and manufactures robust slewing bearings and integrated slew drives for demanding industrial applications. They prioritize longevity and reliability through optimized lubrication engineering, selecting high-performance greases matched to specific operating conditions (extreme temperatures, heavy loads, harsh environments). LYRADRIVE incorporates effective sealing systems and provides clear lubrication guidelines to ensure optimal grease performance throughout the component's service life. Their expertise covers standard and custom solutions for construction, renewable energy, material handling, and automation sectors. For components requiring reliable operation under challenging conditions, contact LYRADRIVE to discuss lubrication requirements and engineered solutions.