What is the Torque of a Slew Drive?

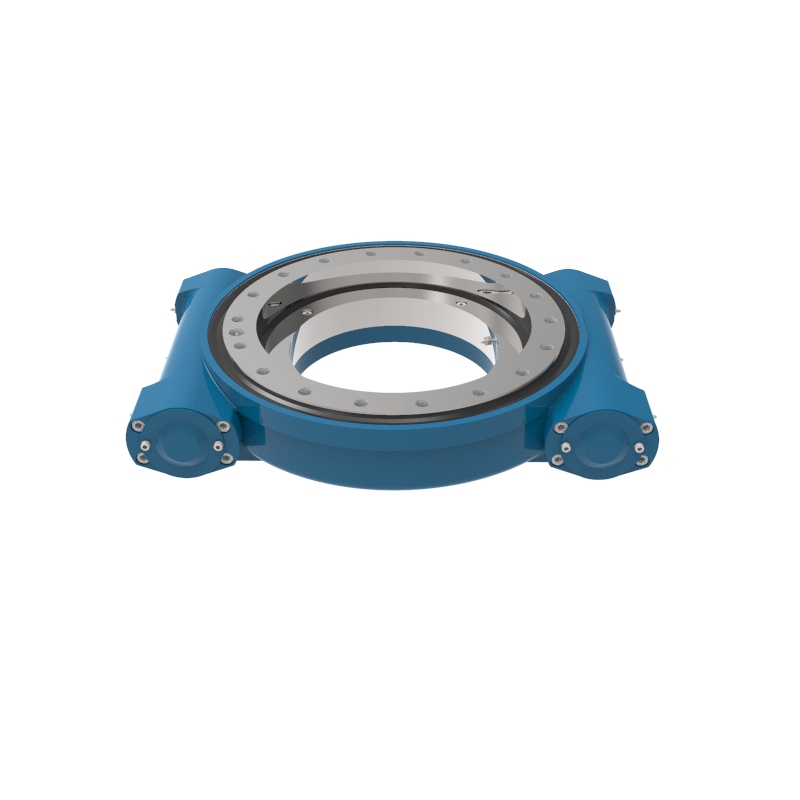

A slew drive is a ready-to-install unit used in various mechanical systems to control rotational movement with both axial and radial forces. The drive combines a slewing bearing with a drive mechanism, typically a worm gear, which engages the gearing of the slewing ring. It is commonly used in applications that require precise and controlled rotational motion, such as solar trackers, wind turbines, satellite dishes, cranes, and robotic arms.

Features of Slew Drive

High Load Capacity: Slew drives can handle a significant amount of axial, radial, and moment loads, making them suitable for heavy-duty applications.

Precision: They offer precise control over movement, which is critical in applications like solar tracking and satellite dish positioning.

Compactness: Integrating the bearing and drive mechanism into a single unit saves space and simplifies design.

Ease of Installation: As a self-contained module, slew drives are relatively easy to install and maintain.

Versatility: They can be customized with different motors (electric, hydraulic, etc.) and sensors to suit specific application needs.

Robustness: Designed to withstand harsh environments, slew drives are typically sealed against dust, dirt, and water.

How to Select a Slew Drive?

Selecting the right slew drive involves considering several factors:

Load Requirements: Determine the axial, radial, and moment loads that the slew drive must support. This will influence the size and type of slew drive needed.

Speed Requirements: Consider the operational speed of the drive. Slew drives generally operate at low to moderate speeds.

Precision and Backlash: Depending on the application, the precision required and acceptable backlash may affect the choice of drive.

Environment: The environmental conditions (temperature, exposure to elements, etc.) will determine the need for additional protections such as sealing or special coatings.

Power Source: Decide whether the drive will be powered by an electric, hydraulic, or other type of motor, based on availability and application needs.

Life Expectancy and Maintenance: Consider how long the drive is expected to operate without maintenance and select a drive that can meet these requirements with minimal upkeep.

What is the Torque of a Slew Drive?

The torque of a slew drive refers to the rotational force it can exert, which is crucial for determining its suitability for particular applications. Torque capacity depends on the size and design of the slew drive, specifically the diameter of the slewing ring and the gear ratio of the worm gear.

Torque is typically provided by manufacturers in their product specifications and can vary widely. For example, small slew drives might offer torque values around a few hundred Newton-meters, while larger industrial models could provide torque in the range of thousands of Newton-meters.

Conclusion

When considering a slew drive for a project, it's important to carefully evaluate the application requirements against the specifications provided by manufacturers. Understanding the expected loads, environmental conditions, and operational parameters will help in selecting the most appropriate slew drive. Manufacturers often provide detailed datasheets and support, which can be invaluable during the selection process.