What is WE Slew Drive

What is a WE Slew Drive?

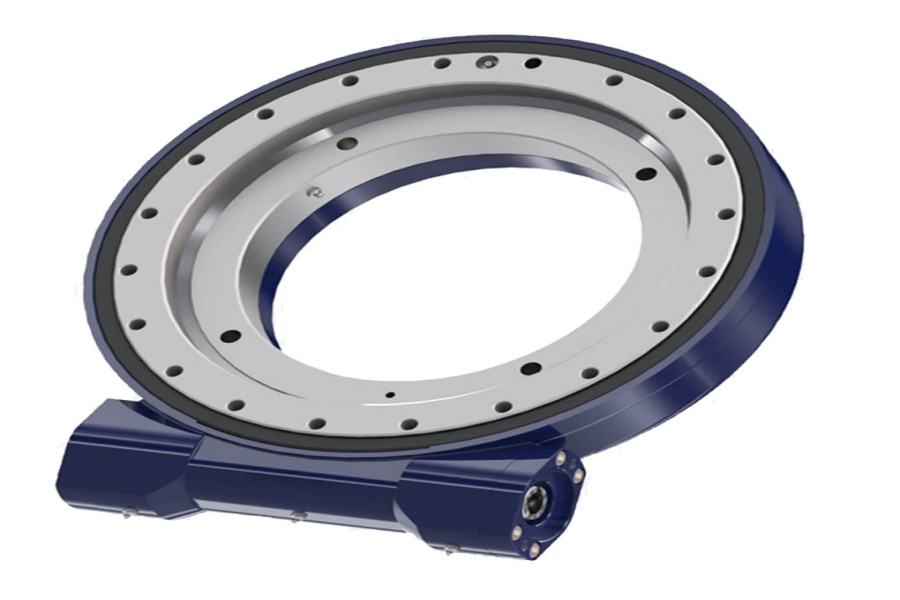

A WE Slew Drive is a highly engineered rotational mechanism designed to provide precise and controlled movement for heavy-duty machinery, combining a slewing ring bearing with an integrated gear system—typically a worm or spur gear configuration. This component is essential for applications requiring smooth 360-degree rotation under substantial loads, such as cranes, solar trackers, or industrial robotics. The "WE" designation often refers to a specific model series or brand variant, emphasizing features like enhanced load distribution, modular design, or customized sealing solutions. Unlike standard slew drives, WE models may incorporate proprietary technologies to optimize torque efficiency, reduce backlash, or withstand extreme environmental conditions, making them a versatile choice for industries demanding reliability and precision in motion control.

Types of WE Slew Drives

WE Slew Drives are categorized based on their gear systems, load capacities, and specialized functionalities. The worm gear WE Slew Drive utilizes a worm and worm wheel pairing, prized for its self-locking capability and high torque output, ideal for applications like satellite antennas or wind turbine yaw systems where safety and stability are paramount. The planetary gear WE Slew Drive employs a compact planetary gearbox for higher efficiency and speed versatility, often used in automated manufacturing lines or medical imaging equipment requiring rapid, precise adjustments. Hollow shaft WE Slew Drives feature a central bore for routing cables or hydraulic lines, making them indispensable in robotics or solar tracking systems where clutter-free rotation is critical. For harsh environments, sealed WE Slew Drives with IP67+ ratings and corrosion-resistant coatings are engineered to endure dust, moisture, or chemical exposure, commonly deployed in marine equipment or mining machinery. Lastly, customized WE Slew Drives offer tailored solutions, such as split housings for easy maintenance or hybrid gear systems blending worm and spur gears for unique torque-speed balances.

Key Features of WE Slew Drives

WE Slew Drives distinguish themselves through a blend of rugged durability and advanced engineering. Their modular construction allows for easy component replacement, minimizing downtime during repairs, while precision-machined gears ensure minimal backlash (often under 10 arc-minutes) for applications demanding exact positioning, such as radar systems or optical telescopes. The integration of high-strength materials like case-hardened steel or bronze alloy gears enhances wear resistance, extending service life even under constant heavy loads. Many WE models incorporate adaptive sealing systems that dynamically adjust to temperature fluctuations, preventing lubricant leakage in sub-zero conditions or dusty worksites. Additionally, smart sensor compatibility enables real-time monitoring of parameters like torque, temperature, and vibration, facilitating predictive maintenance and reducing unexpected failures.

Applications of WE Slew Drives

WE Slew Drives are pivotal in industries where rotational accuracy and load-bearing capacity intersect. In renewable energy, they adjust solar panel angles to maximize sunlight capture or orient wind turbine blades against shifting wind directions. Construction and mining rely on these drives for excavator booms and drilling rigs, where their ability to handle axial, radial, and moment loads simultaneously ensures operational stability. Aerospace and defense applications include missile launcher turrets and satellite dish positioning systems, leveraging their precision and shock resistance. Marine technology employs waterproof WE Slew Drives in ship cranes and sonar equipment, while automated manufacturing uses them in robotic arms for assembly lines, where repeatability and speed are critical. Even medical imaging devices, such as MRI machines, utilize low-noise WE Drives to position patients smoothly and quietly.

Price Range

The cost of a WE Slew Drive varies significantly based on size, complexity, and customization. Entry-level models for light industrial use, such as small conveyor systems, start around 2,000–5,000. Mid-range drives for applications like solar trackers or medium-duty cranes typically range from 8,000–20,000, depending on torque ratings (e.g., 10,000–50,000 Nm) and material upgrades (stainless steel adds 15–25% to the base price). High-end, custom-engineered units for aerospace or defense can exceed $50,000, particularly when incorporating advanced features like integrated sensors, split housings, or extreme-temperature lubrication. Bulk orders or long-term supplier contracts may reduce per-unit costs by 10–20%, while expedited manufacturing or rare material sourcing (e.g., titanium alloys) can increase prices by 30–50%.

Lifespan of WE Slew Drives

A WE Slew Drive’s lifespan hinges on operational intensity, maintenance practices, and environmental conditions. Under moderate use—such as solar farms or periodic industrial automation—these drives can last 15–20 years with routine lubrication and alignment checks. Heavy-duty applications like 24/7 mining operations or offshore cranes typically see lifespans of 8–12 years, assuming annual inspections and timely replacement of worn gears. Harsh environments, such as saltwater exposure or abrasive dust, may shorten longevity to 5–8 years, even with robust sealing. Key longevity factors include avoiding overloading (staying below 80% of max load capacity), using manufacturer-recommended lubricants, and ensuring proper installation alignment (misalignment can halve lifespan by causing uneven gear wear).

How to Choose the Right WE Slew Drive

Selecting the optimal WE Slew Drive requires balancing technical specifications with real-world demands. Begin by calculating load requirements—determine axial, radial, and moment loads using engineering formulas or software simulations, then apply a 1.5x safety factor for dynamic or shock loads. For speed and precision needs, prioritize planetary gear drives for high-RPM tasks or worm gear variants for self-locking safety. Evaluate environmental challenges: sealed drives with IP67+ ratings and corrosion-resistant coatings are non-negotiable for marine or chemical-heavy settings, while standard models suffice for indoor machinery. Consider space constraints—hollow shaft designs simplify cable management in tight installations, and flange-mounted units offer stability for heavy vertical loads.

Material selection is critical: carbon steel suits general industrial use, but stainless steel or bronze alloys are better for corrosive or high-heat environments. Consult suppliers with proven expertise in your industry (e.g., renewable energy or defense) and request load-test certifications or case studies. Finally, factor in total cost of ownership: a cheaper drive may save upfront but incur higher maintenance costs, while premium models with predictive maintenance features reduce long-term expenses.

Common Mistakes to Avoid

Overlooking alignment precision during installation is a frequent error—even a 0.5mm misalignment can accelerate wear, necessitating laser alignment tools for setup. Using incorrect lubricants (e.g., generic grease instead of high-pressure, extreme-temperature variants) leads to premature gear degradation. Ignoring environmental factors—like deploying unsealed drives in dusty mines—invites contamination and failure. Another pitfall is mismatching gear materials, such as pairing a hardened steel worm with a soft alloy wheel, which causes galling and pitting.

Assuming all WE Slew Drives are interchangeable across applications risks performance issues—a drive optimized for slow, high-torque crane operations won’t excel in high-speed robotics. Lastly, prioritizing price over quality often backfires; budget drives may lack hardened components or precision machining, leading to frequent breakdowns and costly downtime.

WE Slew Drive Supplier

LYRA Drive is a professional slewing bearings ,slew drive, slewdrives and gears manufacturer provides customizedslew bearing, drive and gears.For application-specific engineering solutions, contact LYRA to discuss technical specifications and implementation strategies.