What is a Double Worm Slew Drive

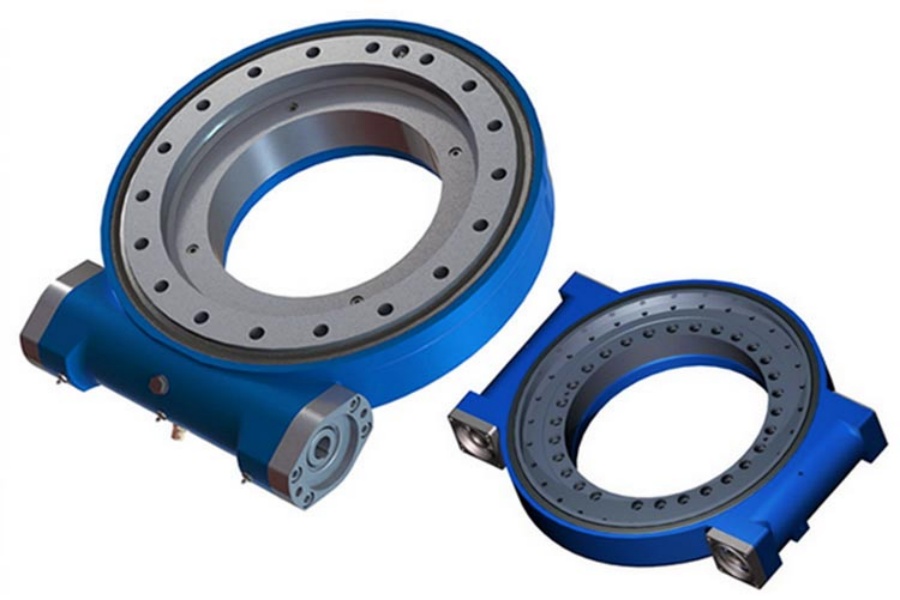

What is a Double Worm Slew Drive?

A Double Worm Slew Drive is a robust rotational drive system engineered with dual worm gears that mesh with a single worm wheel (slewing ring), offering enhanced reliability and performance compared to single worm designs. By integrating two worm gears, this system provides redundancy, allowing continued operation even if one gear fails—a critical safety feature for applications like offshore cranes or heavy machinery. The dual setup not only distributes loads more evenly but also boosts torque capacity, making it ideal for slow-speed, high-torque operations where precision and durability are non-negotiable. Imagine it as a fail-safe mechanism for rotational motion, combining brute strength with smart engineering to handle demanding industrial tasks without missing a beat.

Types of Double Worm Slew Drives

Redundant Backup Design:

This type features two independent worm gears that share the workload, ensuring that if one gear fails, the other seamlessly takes over. It’s the go-to choice for safety-critical systems like ship cranes or amusement park rides, where unexpected downtime or failure could lead to catastrophic consequences.

Tandem Worm Drive:

Designed for raw power, this variant uses two worms operating in parallel to double the torque output, making it indispensable for heavy-duty applications such as mining excavators or tunnel boring machines that face relentless loads and harsh operating conditions.

Hollow Shaft Double Worm:

Built with a central hollow shaft, this design simplifies cable or hydraulic line routing through the drive, offering a clean and organized setup for robotics or solar trackers where clutter-free movement is essential.

Sealed vs. Open:

Sealed drives come with IP67+ ratings to block water, dust, and debris, ideal for environments like mining sites or marine applications. Open drives, while requiring more frequent maintenance, allow customization of lubrication for specialized scenarios.

High-Precision Double Worm:

Engineered with ultra-low backlash gears, this type caters to tasks demanding pinpoint accuracy, such as radar systems or medical imaging equipment, where even minor deviations could compromise performance.

Key Features of Double Worm Slew Drives

The standout feature of double worm slew drives is their built-in redundancy, ensuring uninterrupted operation even during partial gear failure—a lifesaver in high-stakes environments like offshore oil rigs or military equipment. These drives deliver nearly double the torque of single worm systems, thanks to the tandem gear arrangement, while retaining the self-locking capability that prevents back-driving when power is cut. Their design minimizes vibration and wear through balanced load distribution, and hardened steel components ensure longevity under shock loads. Modularity adds another layer of practicality, allowing replacement of individual worm gears without dismantling the entire assembly, which slashes maintenance downtime.

Applications of Double Worm Slew Drives

Double worm slew drives shine in industries where reliability and power are paramount. Offshore cranes rely on them to lift heavy cargo in volatile marine environments, where equipment failure could endanger lives or disrupt operations. In mining, they rotate massive excavator platforms under extreme loads, while wind turbines use them to adjust blade pitch or yaw systems in stormy conditions. Amusement rides like Ferris wheels leverage their redundancy for passenger safety, and military applications—think armored vehicle turrets or missile launchers—depend on their precision and durability. Even solar farms benefit, using these drives to position large-scale trackers reliably under harsh sun and weather.

Price Range

The cost of double worm slew drives varies widely based on size, torque requirements, and customization. Smaller models for solar trackers start around 2,000,whileindustrial−gradeunitsforcranesorminingequipmentcanexceed50,000. High-torque models (50,000+ Nm) often cost twice as much as mid-range options due to their reinforced gears and bearings. Materials play a significant role—stainless steel or corrosion-resistant coatings add 25–50% to the base price, while ultra-precise gears for medical or radar systems can inflate costs by 30–70%. Custom features like hollow shafts or split designs tack on an additional 3,000–10,000. For example, a mid-sized tandem worm drive for a mining excavator typically ranges between 15,000and30,000, balancing power and affordability for heavy-duty use.

Lifespan of Double Worm Slew Drives

Lifespan hinges on usage intensity, maintenance practices, and environmental conditions. Light-duty applications like solar trackers can expect 15–20 years of service, while construction cranes operating daily might last 10–15 years. In brutal 24/7 environments like mining, lifespan drops to 5–8 years. Key factors include load management—operating at 70–80% of maximum capacity extends longevity—and lubrication quality. Sealed drives with “lubricated-for-life” grease require minimal upkeep, whereas open designs demand greasing every 6–12 months. Harsh conditions like saltwater exposure or abrasive dust can slash lifespan by 30–50%, emphasizing the need for robust sealing and material choices.

How to Choose the Right Double Worm Slew Drive

Selecting the ideal double worm slew drive requires a strategic approach. Start by calculating torque and speed needs, factoring in safety margins to avoid overloading. For mission-critical applications like offshore cranes, prioritize redundant backup designs, while tandem drives suit pure torque demands in mining or construction. Assess environmental challenges: IP67+ sealing is non-negotiable for wet or dusty sites, and stainless steel coatings combat corrosion in marine settings. Precision tasks like radar positioning demand low-backlash gears (<10 arc-minutes), while hollow shafts streamline cable management in robotics.

When vetting suppliers, prioritize those with industry certifications (ISO 9001, DNV for marine) and proven track records in your sector. Always request load-test reports or case studies to validate performance claims. Maintenance planning is equally crucial—sealed units offer hassle-free operation for years, while open drives require disciplined greasing schedules. Budget-conscious buyers should weigh upfront costs against long-term savings: premium drives may cost more initially but prevent costly downtime in critical operations.

Common Mistakes to Avoid

One major pitfall is neglecting alignment during installation—even minor misalignment accelerates wear, so laser tools are essential for precision. Using the wrong lubricant is another costly error; high-pressure grease suits heavy loads, while synthetic options handle extreme temperatures. Mixing incompatible metals, like steel worms with inferior bronze wheels, risks galling and premature failure. Overlooking heat dissipation in high-torque applications can lead to overheating, so ensure adequate cooling or ventilation. Lastly, skipping real-world load testing invites disaster—never assume rated specs match actual performance without rigorous testing under operational conditions.

Double Worm Slew Drive Supplier

LYRA Drive is a professional slewing bearings ,slew drive, slewdrives and gears manufacturer provides customizedslew bearing, drive and gears.For application-specific engineering solutions, contact LYRA to discuss technical specifications and implementation strategies.