What is Slewing Bearing Clearance?

What is a Slewing Bearing?

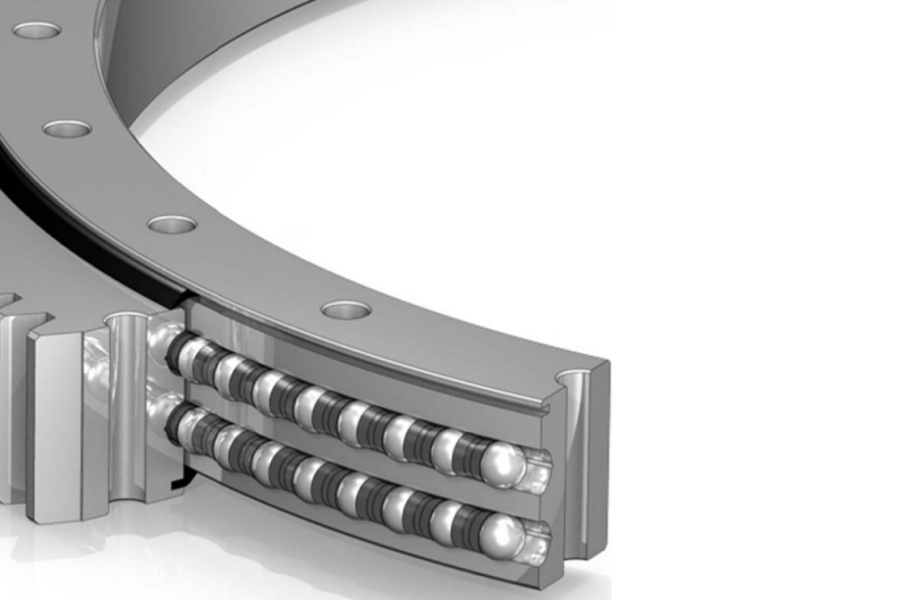

Slewing Bearing, also known as a turntable bearing or slewing ring, is a large-sized bearing that allows rotational movement between two structures while supporting axial, radial, and moment loads. It consists of inner and outer rings with rolling elements (balls or rollers) and often includes gear teeth for driven applications. Widely used in heavy machinery, slewing bearings enable smooth rotation in equipment like cranes, wind turbines, and excavators, making them critical for industrial operations.

What is Clearance in Slewing Bearings and How Does It Affect Performance?

Definition of Clearance

Clearance in slewing bearings refers to the intentional space between the rolling elements and the raceways, which allows for thermal expansion, lubrication, and load distribution. It is categorized into axial clearance (movement along the shaft axis) and radial clearance (movement perpendicular to the axis). Proper clearance ensures the bearing can rotate freely while maintaining structural stability.

Impact of Excessive Clearance

Reduced Load Capacity: Excessive clearance shrinks the load-bearing area, increasing contact stress and accelerating wear.

Compromised Precision: Loose clearance causes misalignment, leading to vibrations, noise, and reduced rotational accuracy, which is critical for applications like medical imaging 设备或精密机器人.

Shortened Lifespan: The combination of stress concentration and vibration significantly reduces the bearing’s fatigue life.

Impact of Insufficient Clearance

Friction and Heat: Tight clearance can result in negative clearance (interference fit) under operational loads, causing rotational resistance and excessive heat generation. This creates a vicious cycle where thermal expansion further reduces effective clearance, potentially leading to seizure.

Installation Challenges: Inadequate clearance fails to compensate for mounting errors, such as uneven surfaces. When bolts are tightened, the bearing may warp, causing uneven stress distribution and operational.

Design and Tolerance Considerations

Manufacturers define clearance ranges based on bearing size and application requirements. A tolerance of ±0.05 mm is typically acceptable for general use, but larger deviations can lead to instability and premature failure. High-precision applications, such as robotics or aerospace, demand near-zero or negative clearance (e.g., -0.02 to 0 mm) to ensure repeatable positioning accuracy.

Key Characteristics of Slewing Bearings

High Load Capacity: Capable of handling combined axial, radial, and moment loads, slewing bearings are ideal for heavy-duty machinery like port cranes and mining equipment.

Compact Design: Their integrated structure eliminates the need for multiple bearings, reducing space and weight while enhancing rigidity.

Self-Lubricating Options: Some designs feature self-lubricating polymer pads, eliminating maintenance needs and extending service life in harsh environments.

Wide Temperature Range: Many slewing bearings operate reliably from -40°C to 120°C, making them suitable for extreme climates.

Customizable Configurations: Available with internal or external gears, corrosion-resistant materials (e.g., stainless steel), and special coatings for specific industries.

Applications of Slewing Bearings

Construction and Mining Machinery

Excavators: Slewing bearings enable 360-degree rotation of the upper structure, ensuring efficient digging and material handling.

Tower Cranes: These bearings support the crane’s rotating jib, handling heavy loads while maintaining stability.

Renewable Energy

Wind Turbines: Yaw and pitch bearings adjust blade angles to optimize energy capture, withstanding high loads and cyclic stresses.

Solar Trackers: Slewing bearings rotate solar panels to follow the sun, maximizing energy output.

Medical and Robotics

CT Scanners and Gamma Knives: Precision slewing bearings ensure smooth, vibration-free rotation for accurate medical imaging and treatment.

Industrial Robots: Bearings in robotic joints enable precise, repeatable movements for assembly and material handling.

Marine and Offshore

Ship Cranes: Heavy-duty slewing bearings operate in corrosive saltwater environments, supporting cargo loading and unloading.

Drilling Rigs: Bearings in rotary tables withstand high torque and axial loads during oil and gas exploration.

Material Handling

Port Cranes and Stackers: These bearings facilitate efficient cargo handling in logistics hubs.

Conveyor Systems: Slewing bearings enable rotating platforms for directional material transport.

Factors Influencing Slewing Bearing Prices

Size and Load Capacity: Larger bearings with higher load ratings (e.g., axial loads exceeding 764,000 lb) are more expensive due to increased material and manufacturing costs.

Material Selection: Stainless steel or ceramic bearings cost more than carbon steel ones but offer superior corrosion resistance and durability.

Precision Requirements: High-precision bearings for medical or aerospace applications require advanced machining, driving up costs.

Customization: Special features like self-lubrication, anti-corrosion coatings, or non-standard gear ratios add complexity and expense.

Market Demand: Prices may fluctuate based on supply chain dynamics and industry demand, such as surges in renewable energy projects.

Brand and Quality: Established manufacturers with rigorous quality control (e.g., ISO certifications) often command higher prices.

Why Choose LYRADRIVE as Your Slewing Bearing Supplier?

LYRADRIVE is a leading provider of high-quality slewing bearings, specializing in customized solutions for industrial, renewable energy, and heavy machinery sectors. With a focus on precision engineering and advanced materials, LYRADRIVE ensures its bearings meet stringent performance standards, including low noise, high durability, and resistance to extreme conditions. The company’s technical expertise and commitment to innovation make it a trusted partner for customers worldwide, offering competitive pricing without compromising on reliability. Contact LYRADRIVE today to explore tailored slewing bearing solutions for your application.