Essential Technical Insights on Worm Gear Slew Drives

What is Worm Gear Slew Drive

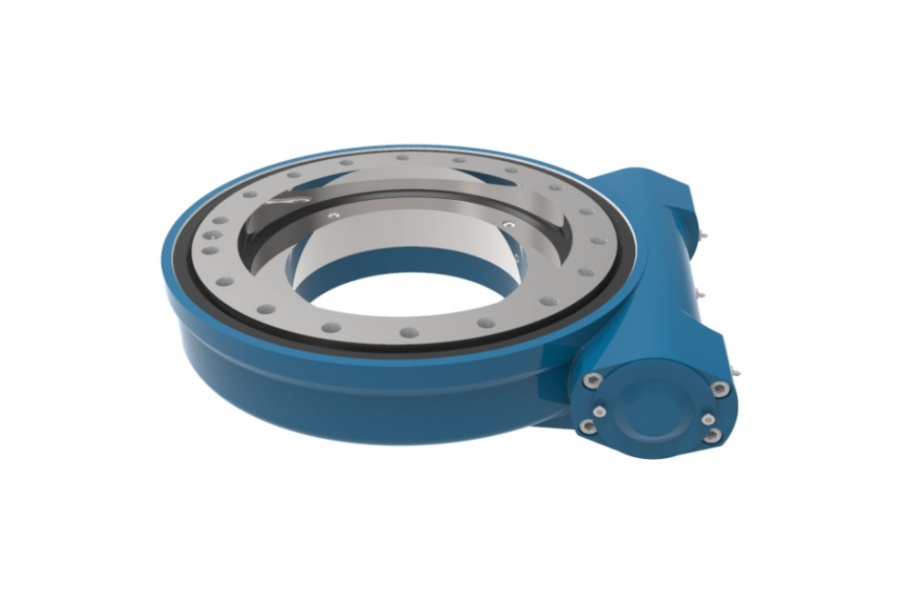

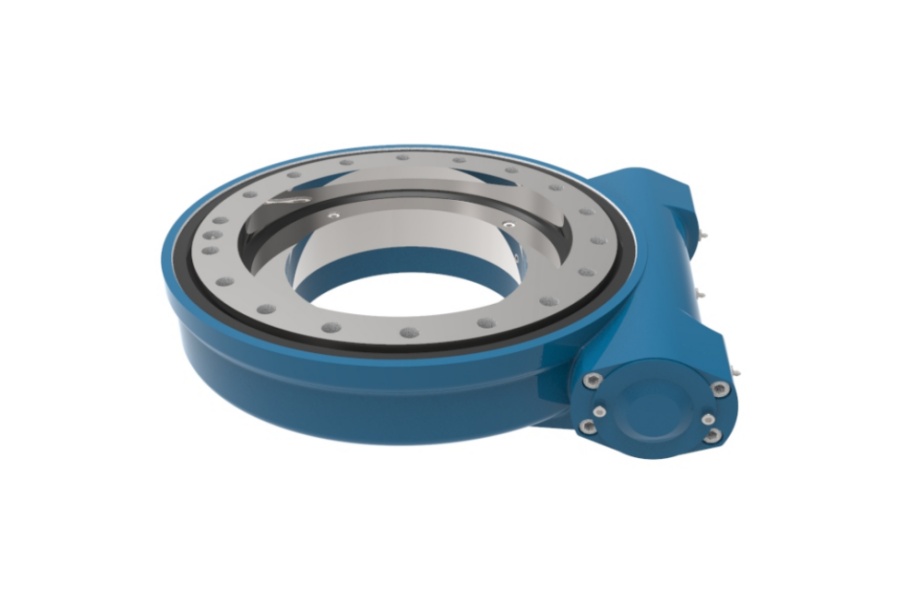

Worm Gear Slew Drive represents a specialized category of slewing drive where the primary reduction mechanism utilizes a worm gear and worm wheel configuration. It is a highly integrated assembly combining a large-diameter slewing bearing (capable of handling combined axial, radial, and moment loads) with a precision worm gear set, typically enclosed within a robust housing. The slewing bearing's internal gear ring acts as the worm wheel, meshing directly with the input worm shaft. This shaft is driven by an external power source, usually an electric motor or hydraulic motor. The entire unit is designed for direct mounting onto host machinery, featuring sealed housings to protect internal components from contamination and retain lubrication.

Essential Technical Information About Slew Drives

Understanding the core technical parameters and operational requirements is crucial for the successful application and longevity of any slew drive, particularly worm gear types:

Construction & Sealing: The housing is typically a robust cast component, providing structural integrity and protection. Critical sealing employs labyrinth seals, often rated IP66 or IP67, to effectively exclude dust, dirt, and moisture ingress, especially vital in harsh environments like construction, mining, or marine applications. High-pressure washing must be strictly avoided, as pressurized water can penetrate seals, leading to contamination, lubrication washout, and premature failure.

Load Capacity & Bearing Type: The integrated slewing bearing determines the drive's fundamental load handling capability (axial force, radial force, and tilting moment). Common types include single-row four-point contact ball bearings (compact, good all-around performance) or cross roller bearings (higher moment stiffness and accuracy). Selection depends entirely on the specific load magnitudes and ratios encountered in the application.

Gear Mechanism - The Worm Advantage: The defining feature is the worm gear set. The worm (a threaded shaft) drives the worm wheel (the gear ring integrated into the slewing bearing's inner or outer ring). This arrangement offers inherent self-locking capability when the drive is not powered, preventing back-driving under load – a critical safety feature in many applications like lifts or positioning systems. However, this also means efficiency is generally lower than spur or helical gear drives.

Backlash Control: Precision machining and adjustment mechanisms for the worm shaft are essential to minimize gear backlash (play between worm and wheel teeth). Controlled backlash is critical for smooth operation, accurate positioning, reduced noise, vibration, and gear wear. High-precision drives incorporate adjustable worm assemblies or preloaded designs.

Lubrication Requirements: Proper lubrication is paramount for performance and lifespan. Drives are factory-filled with specific grease compatible with seals and operating conditions. Key technical considerations include:

Regular Relubrication: Intervals depend on operating conditions (duty cycle, load, speed, temperature, environment). Follow manufacturer guidelines strictly.

Grease Compatibility: Always use the grease type specified by the manufacturer. If changing grease types, rigorous compatibility testing with the original grease and seal materials is mandatory to avoid chemical reactions causing seal degradation or lubrication failure.

Relubrication After Cleaning/Storage: Units cleaned or stored for extended periods (especially beyond 3 years, even unused) require complete regreasing before operation.

Avoid Mixing Greases: Never mix greases with different thickeners or base oils unless explicitly approved as compatible by the grease manufacturer and drive supplier.

Operating Temperature Range: Standard worm gear slew drives are typically rated for operation within an ambient temperature range of -20°C to +70°C. Applications outside this range require special consideration regarding lubrication grease selection (low-temperature flow or high-temperature stability), potential material changes, and seal compatibility.

Efficiency & Thermal Management: Worm gear drives inherently have lower mechanical efficiency compared to other gear types (often 50-90% depending on ratio and design). This energy loss manifests as heat generation. Adequate thermal management (natural convection, sometimes forced cooling) is essential, especially in high-duty-cycle or high-torque applications, to prevent overheating that degrades grease and damages components.

Mounting & Alignment: Precise mounting surface flatness and adequate structural rigidity of the host machine are critical. Distortion during bolt tightening or under operational loads can induce parasitic stresses into the slewing bearing, drastically reducing its fatigue life and causing premature failure. Follow the manufacturer's specified bolt tightening sequence and torque precisely.

Anti-Corrosion Protection: External surfaces often feature protective coatings like paint or specialized plating. The housing casting itself provides significant protection. For highly corrosive environments (marine, chemical), additional protection measures or specific material choices (stainless steel components) may be necessary.

Key Characteristics of Worm Gear Slew Drives

Worm gear slew drives offer a distinct set of advantages and considerations:

Inherent Self-Locking: The worm gear geometry naturally prevents back-driving when the input shaft is not powered, providing crucial safety and holding capability without needing an external brake in many scenarios.

High Reduction Ratios in Single Stage: Capable of achieving very high torque multiplication and reduction ratios within a single compact gear stage.

Compact Design: The integrated nature (bearing, gearing, housing) delivers high torque and load capacity relative to the overall envelope, saving valuable space.

Smooth & Quiet Operation: When properly manufactured and adjusted, worm drives can offer exceptionally smooth and relatively quiet motion transmission.

High Load Capacity & Rigidity: The robust construction and integrated slewing bearing provide excellent resistance to combined loads and high system stiffness.

Sealed for Protection: Effective sealing systems enhance reliability in demanding environments.

Precision Positioning Potential: With low backlash designs, they are suitable for applications requiring accurate positioning.

Considerations:

Lower Efficiency: Significant energy loss as heat compared to other gear types.

Potential Heat Generation: Requires attention to thermal management.

Wear Characteristics: Worm gears can exhibit different wear patterns than spur/helical gears; proper lubrication is critical.

Backlash Sensitivity: Precision requires careful manufacturing and adjustment; backlash can increase with wear.

Primary Applications of Worm Gear Slew Drives

Their unique characteristics make worm gear slew drives ideal for numerous demanding applications:

Solar Tracking Systems: Both single-axis and dual-axis trackers leverage the self-locking and precise positioning capabilities.

Construction Equipment: Excavator attachment rotation (grapples, augers, hammers), crane jib rotation, aerial work platform (boom lift) turntables.

Material Handling: Rotating forklift attachments, automated guided vehicle (AGV) turntables, positioners for welding or handling.

Industrial Automation: Indexing tables, rotary furnaces, mixers, packaging machinery turntables where holding position is critical.

Defense & Aerospace: Radar pedestals, weapon station rotation, optical tracking systems.

Mining Equipment: Rotation mechanisms for drills, feeders, and specialized attachments.

Medical Equipment: Rotation of heavy components within imaging or treatment devices.

Agricultural Machinery: Central pivot irrigation system drives, large spreader turntables.

Marine & Offshore: Deck crane rotation, winch drives, hatch covers, offshore crane auxiliary functions.

Factors Influencing Worm Gear Slew Drive Price

The cost of a worm gear slew drive is determined by a complex interplay of factors:

Size and Load Capacity: Larger diameter drives and those engineered to withstand higher axial, radial, and moment loads require significantly more material, larger bearings, and robust gearing, driving up cost.

Slewing Bearing Type & Quality: The choice (ball vs. roller bearing, specific design like cross roller), material grade (standard hardened steel vs. special alloys), precision class, and manufacturer quality significantly impact the bearing cost, which is a major component.

Worm Gear Specifications: The module (size) of the gear teeth, gear ratio, quality of gear machining (precision, surface finish), material (standard steel vs. bronze worm wheels sometimes used), and backlash tolerance level required all influence cost. High-precision, hardened gears cost more.

Housing Construction: Complexity of the casting or fabrication, material (standard cast iron vs. ductile iron or aluminum), machining requirements, and surface treatment (standard paint vs. specialized coatings) affect price.

Sealing & Environmental Protection: Higher IP ratings (IP67, IP69K), specialized seal materials (e.g., Viton for high temp/chemical resistance), and complex multi-stage labyrinth seals add cost compared to basic sealing.

Input Configuration: Cost varies depending on whether the drive is supplied bare (customer supplies motor), with a standard motor flange, or pre-assembled with a specific motor (electric AC/DC or hydraulic). Hydraulic motor integration often adds significant cost.

Lubrication System: Standard grease fittings vs. provisions for automatic lubrication systems.

Anti-Backlash Mechanism: Drives featuring adjustable worm assemblies or preloaded designs for minimal backlash command a premium.

Customization: Standard catalog items are generally the most economical. Any deviation – custom bolt patterns, special shaft outputs, unique housing shapes, non-standard seals, specific material requirements (e.g., stainless steel) – incurs engineering and manufacturing costs.

Quantity: Unit cost decreases significantly with higher volume production runs due to amortized setup and tooling costs.

1Certifications & Testing: Drives requiring specific third-party certifications (CE, DNV-GL, ABS, ISO) or undergoing extensive load testing and documentation (e.g., FEM 1.001 fatigue testing) increase the price.

Brand & Quality Tier: Established manufacturers with proven reliability, extensive R&D, rigorous quality control, and global support networks typically command higher prices than generic or lesser-known suppliers.

Worm Gear Slew Drive Supplier

LYRADRIVE is a specialized manufacturer focused on the engineering and production of high-performance worm gear slew drives for demanding industrial applications. They leverage expertise in slewing bearing technology and precision gearing to deliver robust, reliable solutions capable of handling significant combined loads while offering essential features like self-locking capability and smooth operation. LYRADRIVE provides a range of standard drives but emphasizes its strong capability in developing custom-engineered slew drives tailored to unique customer requirements, specific load profiles, challenging environmental conditions, and integration needs. Their commitment to quality manufacturing processes, material selection, and rigorous testing protocols aims to ensure longevity and performance in critical sectors such as renewable energy, heavy machinery, automation, and specialized mobile equipment. For detailed technical specifications, application engineering support, or custom project consultation, contacting LYRADRIVE directly to discuss specific needs is recommended.