Selecting Roller Length in Three Row Roller Slewing Bearings

What is Three Row Roller Slewing Bearings

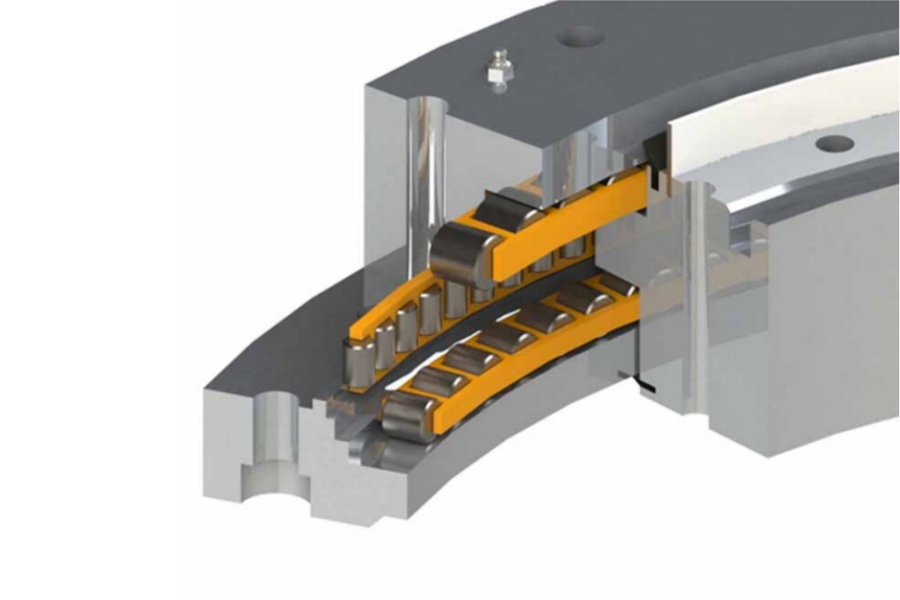

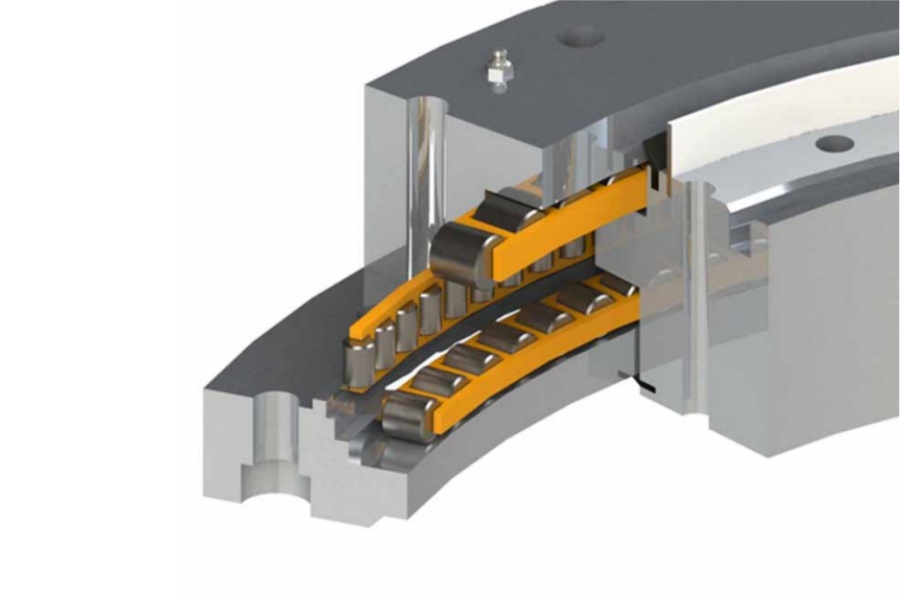

Three Row Roller Slewing Bearings represent a specialized class of slewing rings engineered to withstand exceptionally high combined loads. They feature three distinct, independent raceways stacked vertically within a single, robust bearing assembly. Typically, one raceway is dedicated to handling axial loads (thrust), another is optimized for radial loads, and the third is designed to accommodate large tilting moments (overturning forces). Each raceway contains cylindrical rollers oriented perpendicular to the load direction they are designed to carry. This segregated load path design allows three-row bearings to achieve significantly higher load ratings – particularly for axial force and tilting moments – compared to single-row ball or cross roller designs of similar diameter. They are fundamental components in the most demanding heavy machinery applications.

How to Select Roller Length in Three Row Roller Slewing Bearings

Choosing the optimal roller length is a critical engineering decision with profound implications for bearing performance, longevity, and manufacturability. It's not simply a case of "longer is always better." The selection requires careful consideration of bearing diameter, load requirements, operational dynamics, and manufacturing constraints:

Load Capacity Enhancement Principle: Increasing roller length directly increases the effective contact area between the roller and the raceway. For a given roller diameter and material, longer rollers can distribute applied loads over a larger surface area, thereby increasing the bearing's theoretical static and dynamic load capacity, particularly for axial and moment loads. This is often the primary driver for considering longer rollers in large-diameter bearings.

Bearing Diameter Constraint: Longer rollers are only viable and effective in large-diameter bearings. The fundamental limitation arises from kinematics. On a circular raceway, the ends of a long roller travel at significantly different linear speeds due to the curvature (differential circumferential velocity). In small-diameter bearings, this speed difference becomes extreme.

The Skidding Problem (Small Diameters): In smaller diameter three-row bearings, long rollers cannot roll smoothly. The significant difference in linear speed between the roller's inner and outer ends causes severe parasitic forces. Even with cage guidance, the rollers tend to experience a combination of rolling and skidding/sliding ("creeping") instead of pure rotation. This phenomenon is detrimental:

Increased Friction & Heat: Skidding generates excessive friction, leading to heat buildup.

Accelerated Wear: Skidding causes rapid wear on both roller ends and raceway surfaces.

Reduced Efficiency: Power loss increases significantly.

Potential Cage Damage: Forces from skidding rollers can damage or distort cages.

Misalignment & Jamming: Without adequate cage constraint, long rollers can skew or even jam transversely within the raceway, leading to catastrophic failure.

The Solution: Segmented Rollers & Multi-Row Cage Design: To mitigate skidding in large-diameter applications requiring high load capacity, but where kinematics still pose a challenge for single long rollers, the solution is roller segmentation combined with specialized cage designs:

Segmentation: A single long roller is replaced by two or three shorter roller segments placed end-to-end along the circumference.

Multi-Row Cage Design: A sophisticated cage structure is employed, featuring either:

A single, complex cage design with multiple pockets aligned to hold the segmented rollers in distinct rows parallel to the raceway.

Multiple separate cage sections, each guiding a row of segmented rollers.

Kinematic Benefit: Each shorter roller segment experiences a much smaller differential speed across its length. This allows each segment to roll smoothly with minimal skidding, while collectively achieving the load-bearing benefit of the original long roller's contact area.

Key Selection Factors:

Bearing Diameter: The primary determinant. Larger diameters (> several meters) can accommodate longer rollers or segments more effectively. Minimum viable diameter increases with desired roller length.

Required Load Rating: The target axial, radial, and moment loads dictate the necessary contact area. Roller length (or segment length and number) is a key variable to achieve this.

Operating Speed: Higher rotational speeds exacerbate skidding forces. Slower speeds are more forgiving of longer rollers/segments.

Lubrication Effectiveness: Maintaining a robust elastohydrodynamic lubricant (EHL) film over the entire extended contact length is crucial to prevent wear and scuffing. Longer contact lines can challenge lubrication distribution.

Manufacturing Precision: Fabricating perfectly straight, long raceways and ensuring precise roller geometry/profile along the entire length is more challenging and costly. Raceway crowning becomes more critical for longer rollers to avoid edge stressing. Segmentation adds manufacturing complexity.

Cage Design & Strength: Designing and producing cages capable of reliably guiding multiple rows of segmented rollers without distortion under heavy load requires advanced engineering and robust materials.

Cost vs. Performance: Longer rollers or segmented solutions increase material cost and manufacturing complexity. The benefit in load capacity must justify this cost premium.

In Summary: Roller length selection involves a careful trade-off. For large diameters, increasing roller length (or using segmented rollers) is a powerful method to boost load capacity. For smaller diameters, standard roller lengths must be used to ensure reliable rolling motion and avoid destructive skidding. Collaboration with experienced bearing engineers during the design phase is essential to optimize roller length/segmentation based on the specific application requirements and constraints.

Key Characteristics of Three Row Roller Slewing Bearings

Three-row roller slewing bearings possess distinct features enabling their use in ultra-heavy-duty applications:

Exceptional Load Capacity: Unmatched ability to handle extremely high combined loads – massive axial thrust, significant radial loads, and large tilting moments – simultaneously within a single unit.

Segregated Load Paths: Dedicated raceways for different load types (axial, radial, moment) prevent interaction and optimize load distribution, maximizing overall capacity and stiffness.

High Stiffness & Rigidity: The triple-row design and cylindrical rollers provide superior resistance to elastic deformation under load, ensuring precise positioning and structural stability.

Robust Construction: Manufactured from high-grade, hardened alloy steels using specialized heat treatment processes to withstand extreme stresses.

Designed for Heavy Shock Loads: The inherent robustness makes them suitable for applications experiencing significant impact or shock loading.

Large Diameter Capability: Commonly manufactured in very large diameters (often exceeding 5 meters, up to 15+ meters), essential for giant cranes and excavators.

Complexity: More complex design, manufacturing, and installation compared to single-row bearings.

Higher Cost: Significantly higher material and manufacturing costs due to size, complexity, and precision requirements.

Weight: Substantial weight due to massive structural components.

Lubrication Demands: Require robust, often centralized, automatic lubrication systems to ensure adequate grease reaches all three raceways and numerous rollers.

Primary Applications of Three Row Roller Slewing Bearings

Their unparalleled load capacity makes them indispensable in the largest and most demanding machinery:

Large Crawler Cranes: Super-lift attachments, main slewing ring supporting the entire upper works.

Mining Excavators: Ultra-class hydraulic mining shovels and rope shovels, handling massive bucket loads.

Draglines: Supporting the enormous weight and dynamic loads of the boom, machinery deck, and bucket.

Tower Cranes: Very high-capacity luffing jib tower cranes, especially at the jib foot connection.

Offshore Cranes: Heavy-lift cranes on vessels and platforms for subsea construction, pipe-laying, and lifting modules.

Bucket Wheel Excavators: Critical for the massive rotating superstructure supporting the bucket wheel boom.

Ship Loaders/Unloaders: Handling high-capacity, continuous loading/unloading of bulk carriers.

Large Tunnel Boring Machines (TBMs): Main bearing supporting the rotating cutterhead under immense thrust and moment loads.

Heavy Radar Platforms: Supporting very large, high-inertia radar antennas requiring stability under wind loads.

Specialized Heavy Lifting Equipment: Custom machinery for nuclear, aerospace, or mega-construction projects.

Factors Influencing Three Row Roller Slewing Bearing Price

The cost of these massive bearings is driven by numerous complex factors:

Bearing Diameter: The single most significant cost driver. Larger diameters exponentially increase material volume, forging/rolling complexity, machining time, heat treatment challenges, and handling/transport costs.

Roller Dimensions & Configuration: Larger roller diameters, longer lengths, and the need for segmentation significantly increase material costs and machining/precision grinding complexity. The number of rollers per raceway also impacts cost.

Material Grade & Quality: High-performance, high-purity alloy steels (e.g., 42CrMo, 50Mn) with specific hardenability characteristics are essential. Premium grades and stringent material certification (e.g., vacuum degassing) add cost. Quantity of material is massive.

Heat Treatment: Sophisticated and controlled processes like case hardening (carburizing) or induction hardening over large surfaces are essential for performance but are extremely energy-intensive and time-consuming, especially for massive components. Uniformity and distortion control are major challenges adding cost.

Precision Machining & Grinding: Achieving tight tolerances for raceway geometry, surface finish (Ra), parallelism, and perpendicularity on large, heavy components requires specialized, high-precision CNC machines and skilled labor. Machining time is extensive. Grinding hardened raceways to final dimensions is a critical, high-cost step.

Cage Design & Manufacturing: Complex cages for segmented rollers (multi-row designs) require advanced engineering and manufacturing, often using high-strength materials like bronze alloys or engineered polymers. Precision stamping or machining is costly.

Gear Teeth (If Included): Machining large-diameter internal or external gear teeth to precise tolerances adds significant manufacturing time and cost. Gear hardening (flame or induction) is another critical step.

Sealing Systems: Designing and manufacturing effective, durable seals for large diameters in harsh environments (often requiring multiple sealing rows or complex labyrinth designs) contributes to cost.

Lubrication Provisions: Integrating grease channels, numerous lubrication points (zerk fittings), and potentially ports for centralized systems adds manufacturing steps.

Quality Control & Testing: Rigorous non-destructive testing (NDT - UT, MT, PT) throughout manufacturing, dimensional inspection at multiple stages (CMM), and potentially full-scale load testing (FEM 1.001 standard or custom) are essential but costly. Documentation requirements are high.

Customization: Deviations from standard designs (special mounting flanges, bolt patterns, seal types, material specifications, non-standard gear modules) require engineering effort and disrupt standard manufacturing flow, increasing cost.

Certifications: Meeting specific industry certifications (e.g., DNV-GL, ABS, Lloyd's Register for marine; CE) involves additional audits, documentation, and potentially specific material/process requirements.

Transportation & Handling: The logistics of moving, storing, and handling extremely heavy and oversized components require specialized equipment and planning, adding significant expense.

Manufacturer Expertise & Reputation: Bearings from established manufacturers with proven experience in ultra-large three-row designs command a premium due to reliability, engineering support, and quality assurance.

Three Row Roller Slewing Bearing Supplier

LYRADRIVE possesses specialized expertise in the design and manufacturing of high-capacity slewing solutions, including robust Three Row Roller Slewing Bearings. They focus on engineering bearings tailored to meet the extreme load demands of heavy machinery, emphasizing structural integrity, precision manufacturing, and reliable performance under challenging conditions. LYRADRIVE leverages advanced engineering capabilities to optimize critical parameters like roller length and segmentation strategies, alongside sophisticated cage designs, ensuring smooth operation and longevity in critical applications. Their commitment to rigorous quality control throughout the manufacturing process and material selection aims to deliver bearings capable of meeting the stringent requirements of sectors like heavy mining, large-scale construction, and offshore lifting. For projects requiring custom-engineered large-diameter three-row roller bearings, contacting LYRADRIVE to discuss specific load cases, dimensional constraints, and performance goals is recommended.