What is a Worm Gear Slew Drive

What is a Worm Gear Slew Drive?

A worm gear slew drive is a mechanical device that combines a worm gear (a screw-like gear) and a slewing ring (a rotating bearing) to provide controlled rotational movement with high torque and self-locking capabilities. The worm gear meshes with a worm wheel (a gear with teeth angled to match the worm), creating a compact system that can rotate heavy loads slowly and precisely. The "self-locking" feature means the drive holds its position without external brakes when power is off – perfect for safety-critical applications like cranes or solar trackers.

Types of Worm Gear Slew Drives

Single Worm Gear Slew Drive:

One worm gear paired with a worm wheel. Simple, cost-effective, and common in light-to-medium duty applications.

Double Worm Gear Slew Drive:

Two worm gears for higher torque and redundancy (if one fails, the other keeps working). Used in heavy machinery.

Gear-Integrated Slew Drive:

Combines the worm gear with additional planetary or spur gears for higher efficiency or speed customization.

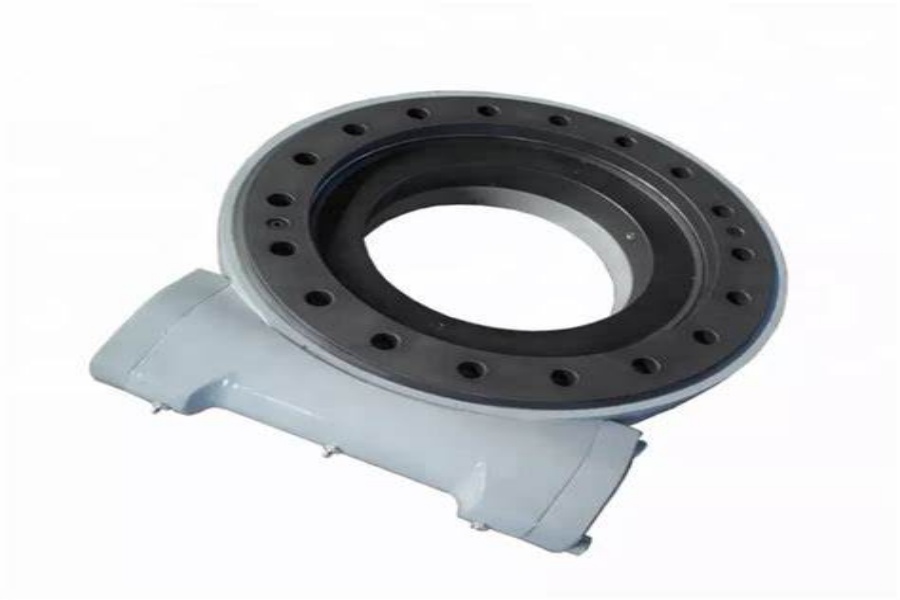

Hollow Shaft Slew Drive:

Central hollow shaft for routing cables, hydraulic lines, or shafts through the drive.

Sealed vs. Open:

Sealed drives block dust and water (IP65+ rating); open drives allow custom lubrication.

Key Features of Worm Gear Slew Drives

Self-Locking: The worm gear’s design prevents back-driving – no brakes needed to hold position.

High Torque, Low Speed: Ideal for slow, powerful rotation (e.g., tilting solar panels).

Compact Design: Combines gearbox and bearing into one unit, saving space.

Durability: Hardened steel gears and bearings handle shock loads and heavy use.

Precision Control: Adjustable backlash (gear play) for accurate positioning.

Low Maintenance: Sealed units with "lubricated-for-life" grease.

Applications of Worm Gear Slew Drives

Solar Trackers: Adjust solar panels to follow the sun’s movement.

Cranes & Construction Equipment: Rotate booms or platforms safely.

Satellite Antennas: Precise positioning for communication dishes.

Medical Imaging: Move heavy MRI or CT scanner components smoothly.

Wind Turbines: Adjust blade pitch or yaw systems.

Robotics: Heavy-duty robotic arms in manufacturing.

Price Range

Prices depend on size, complexity, and customization:

Small Drives (for solar trackers):

500–2,000.

Medium Drives (construction equipment):

15,000–50,000+.

Factors affecting cost:

Torque Rating: Higher torque = larger gears = higher cost.

Material: Stainless steel or corrosion-resistant coatings add 20–40%.

Precision: Low-backlash gears (for medical/optical use) cost 2–3x more.

Brand: European brands (Bonfiglioli, Liebherr) are pricier than Asian suppliers.

Lifespan of Worm Gear Slew Drives

Lifespan varies with use and care:

Light Duty (solar trackers, occasional use): 15–20 years.

Medium Duty (construction, daily use): 8–12 years.

Heavy Duty (mining, 24/7 operation): 5–8 years.

Key factors:

Lubrication: Poor greasing wears gears 3x faster.

Load: Operating above 80% of max load rating halves lifespan.

Environment: Dust, salt, or moisture accelerates corrosion.

How to Choose the Right Worm Gear Slew Drive

Follow these steps to avoid buying the wrong drive:

Calculate Your Torque & Speed Needs

Torque: Determine the rotational force required (in Nm or lb-ft).

Speed: Worm gear drives are slow – typical output speeds range from 1–30 RPM.

Confirm Self-Locking Requirements

Do you need the drive to hold position without power? If yes, worm gears are ideal.

If not, consider more efficient options (e.g., planetary gears).

Assess Environmental Conditions

Sealing: IP65+ for outdoor or dusty/wet environments.

Corrosion Resistance: Stainless steel or coatings for marine/chemical exposure.

Temperature: Standard drives work in -20°C to +100°C. Extreme temps need special grease.

Mounting & Space Constraints

Hollow Shaft: Needed for routing cables?

Flange vs. Foot Mounting: Flanges save space; foot mounts are sturdier.

Size: Measure available space – worm gear drives are compact but vary in dimensions.

Backlash Tolerance

Low Backlash: Critical for precision tasks (e.g., satellite antennas).

Standard Backlash: Acceptable for most industrial uses.

Efficiency Considerations

Worm gears are 60–70% efficient (lose 30–40% energy as heat).

For high-efficiency needs, pair with a planetary gearbox.

Supplier Reliability

Check for certifications (ISO 9001) and industry experience.

Ask for load-test reports or case studies in your field.

Maintenance Plan

Sealed Units: Low maintenance but can’t be relubricated.

Grease Ports: Allow re-greasing every 1–2 years (check manual).

Budget vs. Performance

Budget Option: Suitable for non-critical, low-duty applications.

Mid-Range: Best for most industrial uses.

Premium: Mandatory for safety-critical roles (e.g., cranes, medical).

Test Before Committing

Request a sample for load and environmental testing.

Check for overheating, noise, or vibration under max load.

Common Mistakes to Avoid

Ignoring Efficiency Loss: Worm gears waste energy as heat – not ideal for continuous high-power use.

Mismatched Load Ratings: Overloading causes rapid gear wear and failure.

Poor Lubrication: Using the wrong grease type or interval kills the drive.

Ignoring Backlash: Too much play ruins precision; too little causes binding.

Wrong Material Pairing: Mixing steel worms with bronze wheels? Ensure compatibility to avoid galling.

Worm Gear Slew Drive Supplier

LYRA Drive is a professional slewing bearings ,slew drive, slewdrives and gears manufacturer provides customizedslew bearing, drive and gears.For application-specific engineering solutions, contact LYRA to discuss technical specifications and implementation strategies.