What is a Truck Crane Slewing Bearing?

What is a Truck Crane Slewing Bearing?

A Truck Crane Slewing Bearing is the rotating heart of a truck-mounted crane, enabling the crane’s upper structure (boom, cab, etc.) to swivel 360° smoothly while supporting heavy loads. Think of it as a giant, ultra-strong "lazy Susan" that handles massive weights, shocks, and vibrations. It’s built to endure the rough life of construction sites, highways, and off-road terrain. Without it, the crane couldn’t lift, swing, or position loads precisely. These bearings combine high load capacity with compactness to fit the tight space and weight limits of a mobile crane.

Types of Truck Crane Slewing Bearings

Single Row Ball Slewing Bearing:

Uses a single row of balls to handle moderate axial and radial loads.

Best for: Smaller truck cranes with lighter lifting capacities.

Double Row Ball Slewing Bearing:

Two rows of balls for higher load capacity and better moment load resistance.

Best for: Mid-sized cranes needing a balance of strength and cost.

Cross Roller Slewing Bearing:

Cylindrical rollers arranged in a cross pattern (90°) to manage heavy axial, radial, and moment loads.

Best for: Heavy-duty truck cranes lifting extreme weights (e.g., 100+ tons).

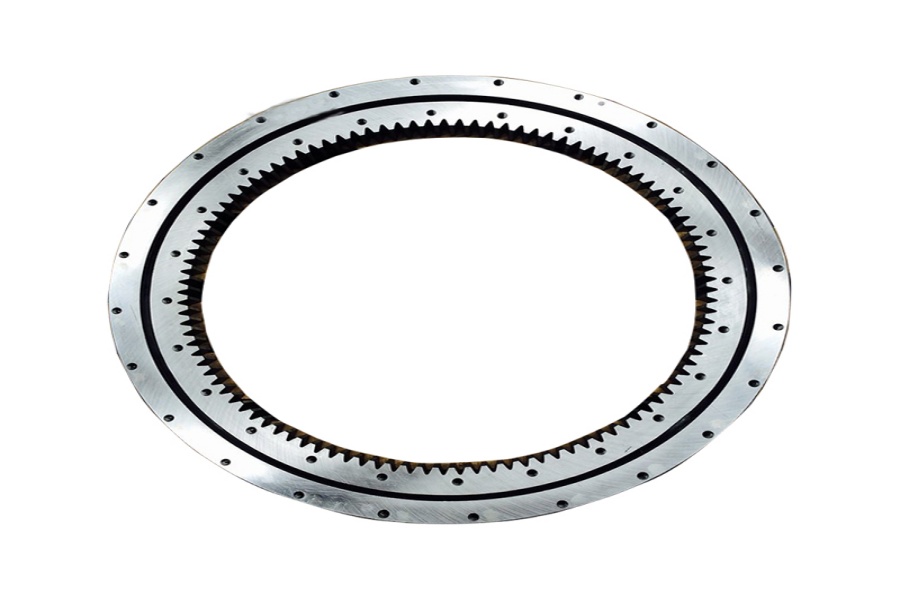

Gear-Integrated Types:

Inner or outer ring has gear teeth to connect directly to the crane’s hydraulic motor.

Best for: Cranes requiring precise rotation control.

Sealed vs. Open:

Sealed bearings block dirt and water (critical for dusty job sites).

Open bearings allow custom grease but need frequent maintenance.

Key Features of Truck Crane Slewing Bearing

Extreme Load Capacity: Handles the crane’s max load + safety margins. Axial loads (vertical) from the boom weight, radial loads (sideways) from swinging cargo, and moment loads (tilting) from off-center lifts.

Shock Resistance: Built to survive sudden loads, like dropping a heavy object or abrupt stops.

Compact & Lightweight: Fits the crane’s limited space without adding unnecessary weight.

Corrosion Protection: Coatings (zinc, epoxy) or stainless steel for cranes working near saltwater or chemicals.

Low Maintenance: Sealed units with long-life grease for minimal downtime.

Precision Rotation: Smooth movement even under max load—no jerking or sticking.

Applications of Truck Crane Slewing Bearing

Construction Sites: Lifting steel beams, concrete panels, or machinery.

Utility Work: Installing power lines, telecom towers, or transformers.

Emergency Services: Recovery operations (e.g., overturned trucks).

Logistics: Loading/unloading heavy cargo from trucks or ships.

Oil & Gas: Handling pipes and equipment in remote locations.

Price Range

Truck crane slewing bearings aren’t cheap, but they’re cheaper than a crane breakdown. Costs depend on:

Size: Small bearings (for 10-ton cranes) start at ~

2,000.Massivebearings(100+toncranes)canhit30,000+.

Type: Cross roller bearings cost 20–40% more than ball bearings.

Material: Alloy steel adds 15–25% over carbon steel.

Customization: Gear teeth, special seals, or coatings add

1,000–5,000.

Brand: European/Japanese brands (SKF, IKO) are pricier; Chinese brands offer budget options.

Example: A mid-sized double row ball bearing for a 50-ton crane costs

8,000–15,000.

Lifespan of Truck Crane Slewing Bearing

Lifespan depends on:

Usage Intensity: A crane working daily on a skyscraper project wears out bearings faster than one used weekly.

Maintenance: Greasing every 500–1,000 hours extends life. Neglect = 50% shorter lifespan.

Environment: Salt, dust, or extreme temps accelerate wear.

Load Habits: Overloading is the #1 killer.

Typical Lifespan:

Light use (occasional lifting): 10–15 years.

Heavy use (daily construction): 5–8 years.

Harsh environments (offshore/mining): 3–6 years.

How to Choose the Right Truck Crane Slewing Bearing

Don’t guess—follow these steps to avoid a costly mismatch:

Calculate Your Loads

Axial Load: Total weight of the crane’s upper structure (boom, cab, etc.).

Radial Load: Side forces from swinging loads or wind.

Moment Load: Tilting force when lifting off-center (use formula: Load Weight x Distance from Center).

Pro Tip: Add a 1.5x safety factor to your max calculated load.

Match the Bearing Type to Your Crane

Small Cranes (≤20 tons): Single row ball bearings (cheap, light).

Mid-Sized Cranes (20–80 tons): Double row ball or cross roller bearings.

Heavy Cranes (80+ tons): Cross roller bearings (handles brutal loads).

Gear or No Gear?

Gear-Integrated: Necessary if your crane uses a direct-drive rotation motor.

Gearless: Choose if rotation is driven externally (e.g., hydraulic motor via chain/belt).

Environmental Fit

Seals: IP67+ sealing for dusty or wet job sites.

Corrosion Resistance: Stainless steel or coatings for coastal or chemical exposure.

Temperature: Standard bearings work in -30°C to +120°C. For hotter/colder, pick special grease.

Size & Weight Limits

Measure the available space on your crane’s turntable.

Check weight limits—heavy bearings reduce lifting capacity.

Supplier Red Flags

No load-test reports or certifications.

Can’t provide references from crane manufacturers.

Warranty shorter than 1 year.

Installation & Alignment

Use laser alignment tools during installation. Misalignment kills bearings fast.

Follow torque specs for bolts—over-tightening warps the bearing.

Maintenance Plan

Sealed Bearings: “Fit and forget” for 2–5 years (no regreasing).

Open Bearings: Grease every 500 hours (check the manual).

Budget vs. Reliability

Budget Pick: Acceptable for older cranes or backup equipment.

Mid-Range: Best for most working cranes.

Premium: Non-negotiable for new or safety-critical cranes.

Test Before Full Purchase

Run the bearing under simulated loads (if possible).

Check for abnormal heat, noise, or vibration.

Common Mistakes to Avoid

Ignoring Shock Loads: Sudden drops or jerks can exceed the rated load—always factor these in.

Wrong Lubricant: Using cheap grease that breaks down under high heat.

DIY Repairs: Replacing rollers without proper tools/training = guaranteed failure.

Mismatched Materials: Pairing a carbon steel bearing with stainless bolts causes galvanic corrosion.

Skipping inspections: Catching a cracked raceway early saves a significant amount of money.

Truck Crane Slewing Bearing Supplier

LYRA Drive is a professional slewing bearings ,slew drive, slewdrives and gears manufacturer provides customizedslew bearing, drive and gears.For application-specific engineering solutions, contact LYRA to discuss technical specifications and implementation strategies.