What is a Single Row Cross Roller Slewing Bearing?

What is a Single Row Cross Roller Slewing Bearing?

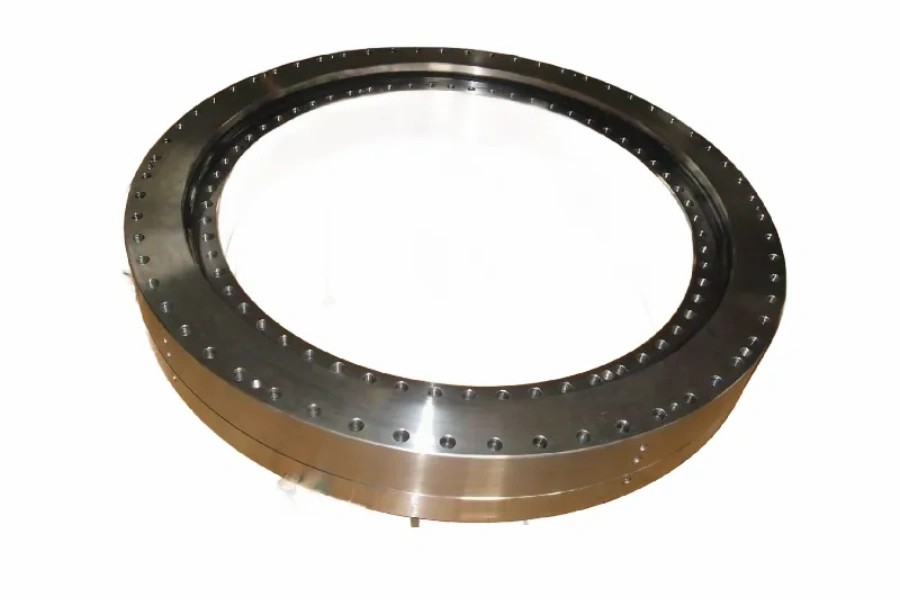

A Single Row Cross Roller Slewing Bearing is a specialized type of rotary bearing designed to handle axial, radial, and moment (tilting) loads simultaneously. Unlike standard bearings, it uses cylindrical or tapered rollers arranged in a cross pattern (90° to each other) within a single row. This unique design maximizes load distribution and rigidity, making it ideal for applications requiring high precision and compactness. Think of it as the “Swiss Army knife” of bearings – it simplifies complex mechanical systems by replacing multiple bearing setups with a single unit.

Types of Single Row Cross Roller Slewing Bearings

Standard Cross Roller:

Basic design with cylindrical rollers in a cross arrangement.

Used in general industrial applications.

Tapered Cross Roller:

Uses tapered rollers for higher load capacity and better alignment.

Common in heavy machinery like cranes.

Gear-Integrated Types:

Features internal or external gear teeth for direct drive integration.

Found in robotics or solar trackers.

Flange-Mounted:

Includes mounting flanges for easy installation.

Popular in medical imaging devices.

Sealed vs. Open:

Sealed types have rubber or metal shields to block dust/water.

Open types allow for custom lubrication but require more maintenance.

Key Features of Single Row Cross Roller Slewing Bearings

High Load Capacity: Handles all-directional loads in a single row.

Compact Design: Saves space by combining axial/radial support into one unit.

Precision: Low rotational resistance and minimal deflection for accurate positioning (e.g., robotic arms).

Durability: Hardened steel rollers and raceways resist wear.

Lightweight: Aluminum alloy options available for weight-sensitive applications (e.g., drones).

Customizable: Options for gear teeth, seals, lubrication ports, and mounting holes.

Applications of Single Row Cross Roller Slewing Bearings

Industrial Robots: Provides precise rotation for robotic joints.

Medical Equipment: MRI machines, CT scanners, and surgical robots.

Solar Trackers: Rotates solar panels to follow the sun.

Machine Tools: Rotary tables for CNC machining.

Aerospace: Satellite antennas and drone gimbals.

Construction Equipment: Compact cranes and excavators.

Price Range

Prices vary based on:

Size: Small bearings (e.g., 100mm diameter) start at ~

200.Largeindustrialunits(1,500mm+)canexceed10,000.

Material: Stainless steel costs 20–30% more than carbon steel.

Precision Grade: High-precision bearings (for medical/optical use) cost 2–3x more than standard versions.

Customization: Adding gears, special seals, or coatings increases price by 15–50%.

Brand: Japanese/German brands (IKO, Schaeffler) are premium; Chinese suppliers offer budget options.

Example: A medium-sized (500mm) standard cross roller bearing costs

1,500–3,000.

Lifespan of Single Row Cross Roller Slewing Bearing

Typical lifespan depends on:

Load Conditions: Overloading shortens life. Stick to 70–80% of the rated load for longevity.

Lubrication: Regular greasing (every 6–12 months) prevents wear.

Environment: Harsh conditions (e.g., saltwater, metal dust) cut lifespan by 30–50%.

Installation: Poor alignment causes uneven roller stress.

Average Lifespan:

Industrial robots: 8–12 years.

Medical devices: 10–15 years (light use, clean environments).

Construction equipment: 5–8 years (heavy loads, dusty sites).

Custom Specialists: Suppliers offering tailored designs (gears, seals, materials).

Regional Distributors: Local suppliers reduce shipping costs and lead times.

Online Marketplaces: Platforms like Alibaba or ThomasNet for comparing options.

Red Flags:

No load-test reports or warranties.

Vague material certifications (e.g., “high-quality steel” without specs).

How to Choose the Right Single Row Cross Roller Slewing Bearing

Follow this guide to avoid costly mistakes:

Calculate Your Loads

Axial Load: Vertical force (e.g., weight pressing down on a turntable).

Radial Load: Horizontal force (e.g., a robotic arm extending sideways).

Moment Load: Tilting force (e.g., off-center weight on a rotating platform).

Pro Tip: Use a safety factor of 1.5x your max calculated load.

Define Precision Needs

Backlash: Near-zero backlash is critical for robotics or optical systems.

Runout: Low runout (≤0.01mm) ensures smooth rotation in precision tools.

Assess Environmental Factors

Sealing: IP65+ seals for wet/dirty environments (e.g., construction sites).

Temperature: Standard bearings work at -30°C to +120°C. Extreme temps require special grease.

Corrosion: Stainless steel or coatings for marine/chemical exposure.

Choose the Right Type

Gear-Integrated: For direct motor/drive coupling (saves space).

Tapered Rollers: If shock loads are common (e.g., mining equipment).

Lightweight Alloy: For drones or portable devices.

Check Mounting Requirements

Hole Patterns: Match bolt holes to your machine’s baseplate.

Shaft Compatibility: Ensure inner/outer diameters fit existing shafts.

Flange vs. Standard: Flanges simplify installation but add weight.

Lubrication & Maintenance

Grease Type: High-speed applications need low-viscosity grease.

Service Access: Can you easily reach the bearing for re-greasing?

Sealed vs. Open: Sealed bearings reduce maintenance but limit customization.

Budget vs. Quality

Cheap Options: Risk premature failure – okay for non-critical uses.

Mid-Range: Balance cost and reliability for most industrial apps.

High-End: Necessary for aerospace/medical where failure isn’t an option.

Verify Certifications

Material Certificates: Confirm steel grade (e.g., SAE 52100 for bearings).

Load Test Reports: Ask for proof of dynamic/static load ratings.

Industry Standards: CE, RoHS, or ISO certifications for quality assurance.

Test Before Mass Purchase

Order a sample to check fit, noise, and heat generation under load.

Run accelerated life tests if possible (e.g., 24/7 operation for a week).

Plan for Replacement

Check lead times – custom bearings can take months to produce.

Keep spares if downtime is costly (e.g., production lines).

Common Mistakes to Avoid

Ignoring Moment Loads: Even small off-center weights can wreck the bearing.

Wrong Lubricant: Using generic grease instead of high-temperature/water-resistant types.

Over-Tightening Bolts: Distorts the raceway, causing uneven roller wear.

Mismatched Materials: Pairing a stainless steel bearing with a carbon steel frame risks galvanic corrosion.

Single Row Cross Roller Slewing Bearing Supplier

LYRA Drive is a professional slewing bearings ,slew drive, slewdrives and gears manufacturer provides customizedslew bearing, drive and gears.For application-specific engineering solutions, contact LYRA to discuss technical specifications and implementation strategies.