What Components Make Up a Spur Gear Slew Drive

What is Spur Gear Slew Drive

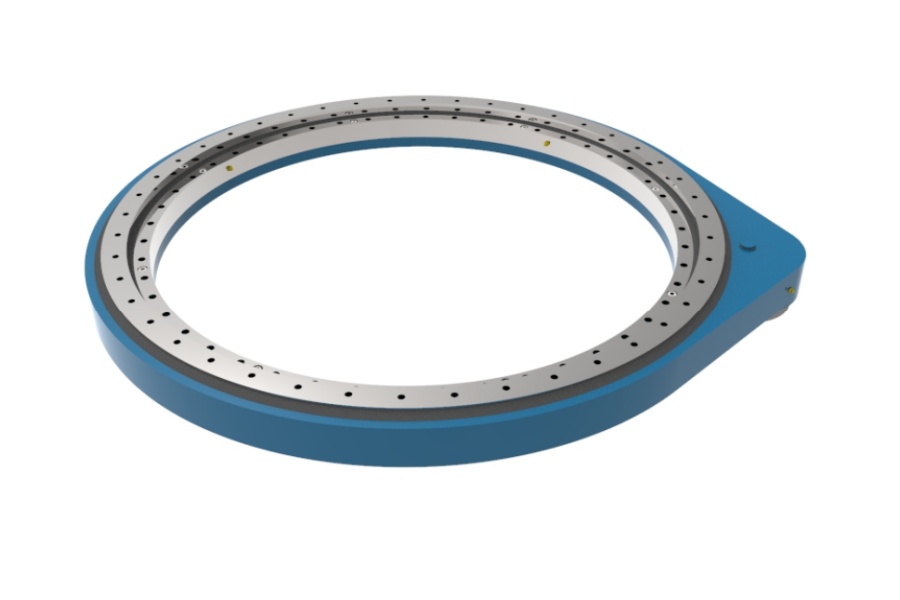

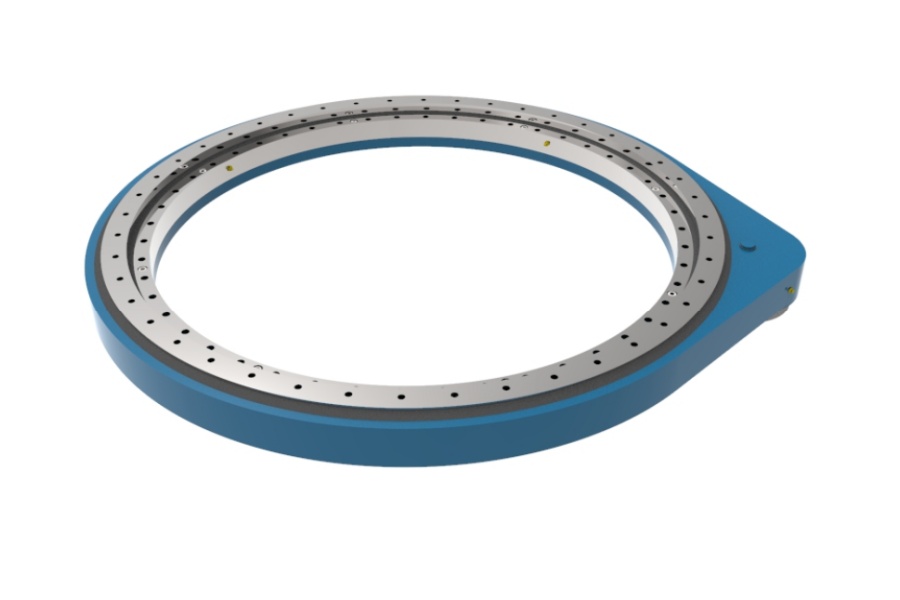

Spur Gear Slew Drive is an integrated mechanical actuator system that combines a slewing bearing with a spur gear and a pinion input into a single, compact, and sealed housing, designed to provide high-torque, controlled rotational movement for a vast array of heavy-duty and precision applications. Unlike simpler rotational components, a slew drive is a complete system solution that transforms a prime mover's input—typically from an electric, hydraulic, or pneumatic motor—into a powerful, slow-velocity output rotation. The defining feature of this drive type is the use of a spur gear, which is characterized by its straight teeth that are parallel to the axis of rotation, machined directly onto the inner or outer ring of the integral slewing bearing. This gear meshes with a smaller pinion gear, and the entire mechanism is encased within a robust housing that serves as both a protective shell and a structural mounting point. This integrated design philosophy eliminates the need for engineers to source and assemble multiple separate components like bearings, gears, and housings, thereby drastically simplifying machine design, reducing assembly time and costs, minimizing spatial requirements, and significantly enhancing overall system reliability by ensuring perfect alignment and protection from external contaminants.

What Components Make Up a Spur Gear Slew Drive

A spur gear slew drive is a complex assembly where the synergistic operation of several precision-engineered components creates a robust and reliable motion system. Understanding the role of each part is crucial for appreciating the drive's overall functionality, specifying the correct unit for an application, and performing effective maintenance. The following elements form the core of every spur gear slew drive.

The heart of the system is the Slewing Bearing. This is not a standard bearing but a large-scale, specially designed unit that acts as the central structural element. It consists of an inner ring and an outer ring, each with precision-hardened and ground raceways. These raceways accommodate the rolling elements—which can be balls or cylindrical rollers—that allow for smooth, low-friction rotation between the rings. The slewing bearing is responsible for supporting the immense combined loads (axial, radial, and moment) imposed by the application. Integrated directly onto one of these rings, typically the outer ring, is the Spur Gear. This is a large-diameter gear with straight teeth that are machined to exacting tolerances. The material and heat treatment of this gear are critical, often involving high-carbon chromium steel that is case-hardened to achieve a extremely hard, wear-resistant tooth surface while maintaining a tough, shock-absorbing core. This gear is the primary source of the drive's high-torque output capability.

Engaging with the spur gear is the Pinion. This is a smaller gear, mounted on a shaft that serves as the input to the system. The pinion is the component that is directly driven by the external power source, such as a hydraulic motor or an electric motor (often via a secondary reducer). The precise meshing between the pinion and the spur gear is what converts the high-speed, low-torque input into the low-speed, high-torque output. The design, including the number of teeth and the gear module, determines the drive's reduction ratio and thus its final output torque and speed characteristics. All of these components are housed within and protected by a rigid Housing or Casing. This is typically a cast or machined structure made from high-strength iron or steel. Its primary functions are to provide a sealed environment, contain lubrication, protect the internal components from dirt, dust, and moisture, and offer a solid base for mounting the entire drive onto machinery and for mounting the drive motor onto itself.

To ensure the integrity of the internal environment, a Sealing System is paramount. This consists of multiple lip seals, often made from Nitrile Rubber (NBR) or other specialized elastomers like Fluorocarbon (FKM) for high temperatures, strategically placed at all potential points of contamination ingress, such as where the pinion shaft exits the housing and between the inner and outer rings of the bearing. Finally, Lubrication Fittings (grease nipples) are installed, allowing for the periodic injection of fresh, high-quality grease into the raceways and onto the gear teeth. This is essential for maintaining a protective film between metal surfaces, reducing wear, dissipating heat, and preventing corrosion, thereby ensuring a long and reliable service life for the entire system.

Characteristics of Spur Gear Slew Drive

Spur Gear Slew Drives are defined by a distinct set of engineering characteristics that make them a preferred solution for applications requiring high torque and controlled rotation in a compact package. Their most prominent feature is their high mechanical efficiency. The engagement of the spur gear teeth results in primarily rolling contact, which generates minimal sliding friction compared to other drive types like worm gears. This leads to lower energy consumption, reduced operational heat generation, and higher overall efficiency, which is particularly advantageous for continuous or high-cycle applications.

Another critical characteristic is their exceptional load-handling capacity and compact, integrated design. The system is engineered to support immense combined loads—axial, radial, and tilting moments—within a single, self-contained unit. The large contact area between the pinion and the spur gear teeth enables the transmission of very high torque. This inherent strength, combined with the structural slewing bearing, eliminates the need for external gearing and complex support structures, drastically simplifying the surrounding machine design and saving valuable space.

Durability and reliability are cornerstone traits. Manufactured from high-strength, hardened steels and housed in a robust casing, these drives are built to perform reliably under severe operational conditions, including exposure to heavy shock loads, temperature variations, and harsh, contaminant-filled environments. The inclusion of high-quality, multi-lipped sealing systems is fundamental to this durability, effectively creating a barrier against abrasive particles and moisture. Furthermore, they offer significant design versatility and customization. Manufacturers can tailor drives with specific gear ratios, various mounting configurations and flange designs, alternative sealing solutions for extreme environments, and a choice of input drive options to precisely match the unique performance requirements of virtually any application, from heavy industrial machinery to precision automation equipment.

Applications of Spur Gear Slew Drive

The application range of Spur Gear Slew Drives is extensive, spanning numerous industries that require reliable, high-torque rotational actuation with high efficiency. They are a fundamental enabling technology in the renewable energy sector, particularly in large-scale solar tracking systems. Here, they are the core component responsible for meticulously adjusting the angle of massive arrays of photovoltaic panels throughout the day to accurately follow the sun's path, thereby maximizing energy capture efficiency and output.

In construction, mining, and heavy equipment, their use is ubiquitous due to their robustness and power. They provide the essential rotational force for excavator upper structures, enabling full 360-degree movement, and are integral to the operation of mobile and tower cranes, facilitating the precise and safe positioning of heavy loads. They are also found in concrete pump trucks, drill rigs, and compactors, where their ability to deliver high torque reliably is critical for operation in the most demanding site conditions.

The material handling and industrial automation sectors utilize them extensively. In ports, they operate the massive rail-mounted gantry cranes that stack and move shipping containers. They are central to automated warehousing systems, functioning in robotic welding and assembly cells, and driving heavy-duty rotary index tables and palletizers where precise positioning under high moment loads is a necessity. Beyond these core areas, their applications are diverse and critical. They are used in defense for radar and satellite antenna positioning systems, in agriculture for controlling large central pivot irrigation systems, and in entertainment for the precise movement of stage equipment and large-scale rotational platforms. This remarkable versatility underscores the spur gear slew drive's role as an indispensable component in modern mechanical engineering and industrial automation.

Factors Influencing the Price of Spur Gear Slew Drive

The price of a Spur Gear Slew Drive is influenced by a complex interplay of technical specifications, material choices, manufacturing processes, and broader commercial factors. Understanding these variables is crucial for making informed procurement decisions and accurately evaluating the value proposition of a given unit. The single most significant cost driver is often the physical size and load capacity. Larger diameter drives, designed to handle higher axial, radial, and moment loads, require substantially more raw material in the form of larger steel forgings for the rings and housing, more extensive machining time on large CNC equipment, and larger, more robust internal components like rolling elements and gears, all of which directly and significantly increase the unit cost.

The required precision tolerance grade and performance specifications dramatically impact the manufacturing cost. A drive built to standard industrial tolerances for a piece of construction equipment will be far more economical than one produced to ultra-precise, micron-level tolerances for a military or aerospace application. High-precision requirements necessitate slower production speeds, more advanced machining and grinding equipment, 100% individual testing and inspection (often including non-destructive testing like magnetic particle inspection), and full material traceability, all of which add substantial labor and overhead expenses.

The complexity of the design and the level of customization are another major determinant of cost. A standard, catalog-specified drive will be the most economical option. Any customizations, such as special sealing arrangements for extreme temperatures or submersion, unique flange or mounting hole patterns, specific shaft configurations on the input side, special surface treatments or coatings (e.g., hard anodizing, nickel plating) for corrosion resistance, or the integration of proprietary sealing technologies, add significant steps, require specialized tooling, and extend engineering time, thereby increasing the final price.

The choice of materials also directly affects the bottom line. While standard hardened alloy steel (e.g., 42CrMo4) is common, applications requiring stainless steel (e.g., 440C) for all wetted parts to resist corrosion in marine or food processing environments will see a significant price increase due to the more expensive material and its more difficult machining properties. Furthermore, the quantity ordered is a fundamental economic factor governed by economies of scale. Large volume production runs allow the manufacturer to amortize high fixed costs (like custom tooling, CNC programming, and first-article inspection) over many units, drastically reducing the price per drive. Conversely, a one-off prototype or a small batch order will have a significantly higher unit cost to cover these initial expenses. Finally, external supply chain factors like global fluctuations in steel and alloy prices, international logistics and shipping costs, and import/export tariffs and duties can also cause fluctuations in the final price offered to the customer.

Supplier of Spur Gear Slew Drive

For engineers and procurement specialists seeking reliable and technically proficient spur gear slew drive solutions, LYRADRIVE offers extensive expertise in the design and manufacture of these integrated systems. The company provides a comprehensive range of both standard and fully custom-designed drives, with a deep understanding of how each component—from the material grade of the slewing bearing rings to the precise geometry of the spur gear teeth and the specification of the sealing system—contributes to the overall performance and durability of the unit. LYRADRIVE's rigorous manufacturing and quality control processes ensure that every drive delivers consistent, reliable performance and long-term durability for the most demanding applications in solar tracking, heavy machinery, industrial automation, and beyond.