How Spur Gear Slew Drive Achieves SelfLocking

What is Spur Gear Slew Drive

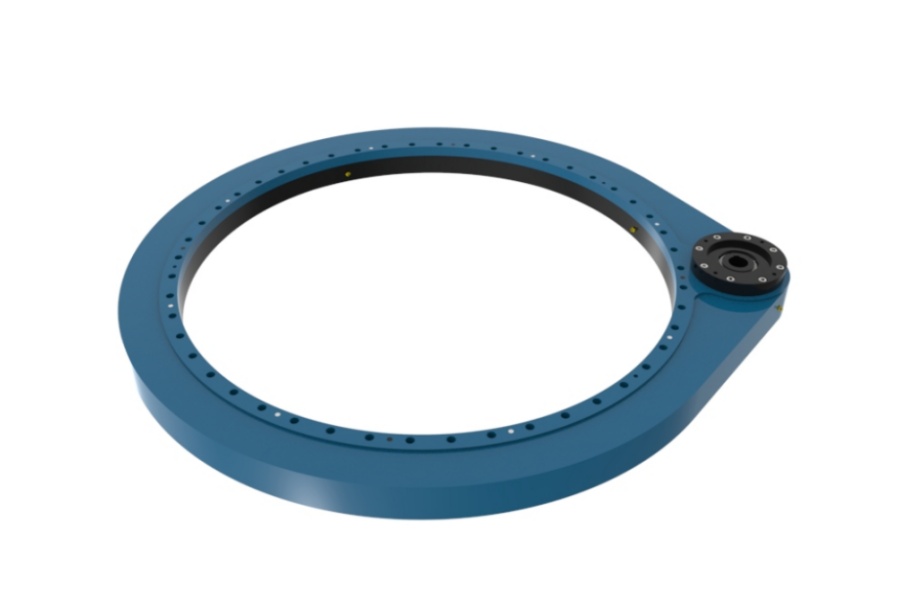

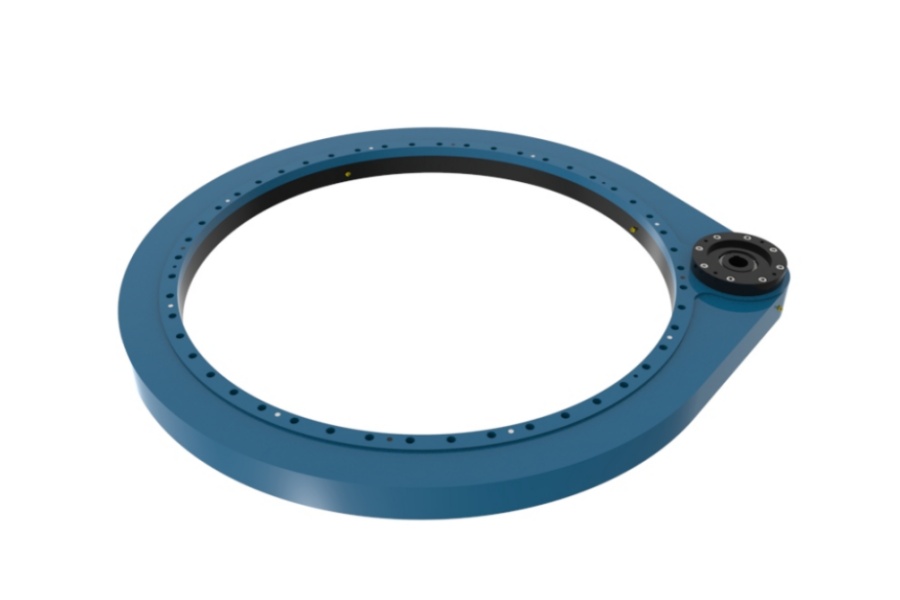

Spur Gear Slew Drive is an integrated mechanical actuator system that combines a slewing bearing with a spur gear ring and a compact housing, creating a self-contained unit designed to provide high-torque, controlled rotational movement for a wide range of heavy-duty applications. Unlike systems that use a worm gear for inherent self-locking, a spur gear drive utilizes a pinion gear that engages directly with the spur teeth machined onto the slewing bearing's outer or inner ring. This configuration offers high efficiency and robust power transmission with minimal energy loss during operation. The enclosed housing protects the internal gearing and bearing from environmental contaminants, contains lubrication, and provides a rigid structure for mounting directly onto machinery. By integrating the rotational support and the drive mechanism into a single, pre-assembled unit, spur gear slew drives simplify machine design, reduce assembly time, and enhance overall system reliability and performance. They are characterized by their straightforward design, high load-bearing capacity, and suitability for applications requiring efficient power transfer and precise positioning when paired with appropriate braking systems.

How Spur Gear Slew Drive Achieves SelfLocking

A fundamental characteristic of a standard spur gear slew drive is its inherent lack of self-locking capability due to the kinematics of the spur gear design. The mating teeth of the pinion and the spur gear interact in a way that does not generate sufficient internal friction to prevent reverse driving; a force applied to the output ring can easily back-drive the input pinion. Therefore, achieving reliable holding torque or "self-locking" in a spur gear slew drive is not an inherent feature but must be accomplished through externally applied or integrated braking methods. The choice of method depends on the required holding torque, operational frequency, safety criticality, and cost considerations.

The most common and efficient method for achieving precise stopping and holding is through the use of a controlled drive motor. When a servo motor is used as the prime mover, its internal feedback system allows for extremely accurate positioning. For applications with relatively low inertial loads, the servo motor can hold its position electronically, resisting movement through its own electromagnetic force. This holding torque is effectively amplified through the drive's gear reduction ratio, providing a significant resisting force at the output stage. Similarly, a brake motor, which incorporates an integral fail-safe electromagnetic disc brake, is a widely used solution. This brake is typically spring-applied and electrically released. When power is supplied to the motor, the brake disengages, allowing rotation. When power is cut—either intentionally for stopping or accidentally during a power failure—the spring immediately engages the brake, bringing the motor shaft to a halt and thereby locking the slew drive against movement.

In hydraulic systems, the method of locking is achieved by preventing oil flow to the hydraulic motor. Several techniques are employed. Using an integral brake on the hydraulic motor itself is a direct approach, functioning similarly to a brake motor. Alternatively, a counterbalance valve or a pilot-operated check valve can be installed in the hydraulic circuit. These valves mechanically block the ports of the motor, trapping hydraulic oil in the lines and effectively creating a hydraulic lock that prevents the motor from turning, thus securing the slew drive. For applications requiring holding in multiple fixed positions rather than continuous resistance, a mechanical locking pin offers a highly secure and fail-safe solution. A hardened steel pin is hydraulically or pneumatically actuated to engage precisely machined holes in the slew drive's mounting flange or rotating structure. Once engaged, this system provides absolute zero-backlash locking, making it ideal for critical applications like heavy-lift cranes or positions that must be maintained indefinitely without any risk of drift, regardless of load or external forces.

For the most demanding applications involving frequent braking under high inertia or high moment loads, a dedicated, independent braking system is often necessary. This involves mounting a large, multi-disc caliper brake directly onto a custom-designed brake disc that is attached to the slew drive's rotating element. This system is designed specifically to handle the immense thermal and mechanical stresses generated during braking, protecting the primary drive train (gears, motor, reducer) from excessive shock loads and wear. This represents the highest-performance solution for ensuring safe and reliable operation in severe-duty cycles.

Characteristics of Spur Gear Slew Drive

Spur Gear Slew Drives are defined by a distinct set of engineering characteristics that make them a preferred solution for applications requiring high torque and efficient rotation in a compact package. Their most prominent feature is their high mechanical efficiency. The engagement of the spur gear teeth results in minimal sliding friction compared to other drive types, translating to lower energy consumption and reduced heat generation during operation. This high efficiency is a key advantage for continuous or high-cycle applications.

Another critical characteristic is their robust load-handling capacity. The design allows for a large contact area between the pinion and the gear teeth, enabling the transmission of very high torque and moment loads. This inherent strength, combined with the integrated slewing bearing, makes them capable of supporting substantial axial, radial, and moment loads simultaneously, all within a single, compact unit. This integrated design philosophy itself is a core trait, combining the bearing, gearing, and structure into one pre-assembled and tested system, simplifying installation and improving overall machine reliability.

Durability and customization are also central to their design. Manufactured from high-strength, hardened steels, these drives are built to withstand severe operational conditions, including heavy shock loads and exposure to harsh environments. The inclusion of high-quality sealing systems is paramount to this durability, effectively keeping out abrasive contaminants. Furthermore, they offer significant design versatility, as they can be customized with different gear ratios, various mounting configurations, alternative sealing solutions, and a choice of input drive options (electric, hydraulic) to precisely match the performance requirements of a vast array of applications.

Applications of Spur Gear Slew Drive

The application range of Spur Gear Slew Drives is extensive, spanning industries that require reliable, high-torque rotational actuation with high efficiency. They are a fundamental enabling technology in the renewable energy sector, particularly in large-scale solar tracking systems, where they meticulously adjust the angle of massive arrays of photovoltaic panels throughout the day to follow the sun's path, thereby maximizing energy capture.

In construction and heavy equipment, their use is widespread due to their robustness. They provide the rotational force for excavator upper structures, allowing for 360-degree movement, and are integral to the operation of mobile and tower cranes, enabling the precise positioning of heavy loads. They are also found in concrete pump trucks and drill rigs, where their ability to deliver high torque is essential for reliable operation in demanding site conditions.

The material handling industry utilizes them extensively in port machinery, such as the massive rail-mounted gantry cranes that stack shipping containers, and in deck cranes on vessels. Their high efficiency and durability are critical for these high-cycle, mission-critical applications. In industrial automation, they are employed in heavy-duty rotary index tables, palletizers, and large robotic welding and assembly cells where precise positioning and high moment load capacity are required.

Beyond these core areas, their applications are diverse. They are used in defense for radar antenna positioning, in agriculture for controlling large central pivot irrigation systems, and in entertainment for staging and rotating platforms. This remarkable versatility, from moving massive solar arrays to positioning sensitive radar equipment, underscores the spur gear slew drive's role as a critical component in modern mechanical design.

Factors Influencing the Price of Spur Gear Slew Drive

The price of a Spur Gear Slew Drive is influenced by a complex interplay of technical specifications, material choices, and commercial factors. The single most significant cost driver is often the size and load capacity. Larger diameters and higher load ratings require more raw material, larger forgings, more extensive machining, and more robust internal components, directly increasing the unit cost.

The required braking or locking system is another major determinant of cost. A standard drive without an integrated brake will be the most economical. Adding an internal brake motor represents a significant cost increase. The most expensive solutions are fully independent, external multi-disc caliper braking systems or complex hydraulic locking circuits, which add substantial cost for the additional components, custom machining, and engineering required.

The complexity of the design and the level of customization are a further major cost factor. A standard, catalog-specified drive will be far more economical than a fully custom-engineered solution. Customizations such as special sealing arrangements for extreme environments, unique flange or mounting hole patterns, specific shaft configurations, and special surface treatments or coatings for corrosion resistance all contribute to higher engineering and production expenses.

The choice of materials also directly affects cost. While standard hardened alloy steel is common, applications requiring stainless steel for all components will see a significant price increase. Furthermore, the quantity ordered is a fundamental economic factor governed by economies of scale. Large volume production runs allow the manufacturer to amortize fixed costs over many units, drastically reducing the price per drive. Finally, external supply chain factors like global steel prices and logistics can also cause fluctuations in the final price.

Supplier of Spur Gear Slew Drive

For engineers seeking reliable and technically proficient spur gear slew drive solutions, LYRADRIVE offers extensive expertise in the design and manufacture of these integrated systems. The company provides a range of standard and custom-designed drives, with a particular focus on integrating the appropriate braking or locking mechanism—from servo control and brake motors to hydraulic locks and physical pin systems—tailored to the specific safety and performance requirements of the application. LYRADRIVE's rigorous manufacturing and quality control processes ensure that its products deliver consistent performance, high torque output, and long-term durability for demanding applications in solar tracking, heavy machinery, and industrial automation.