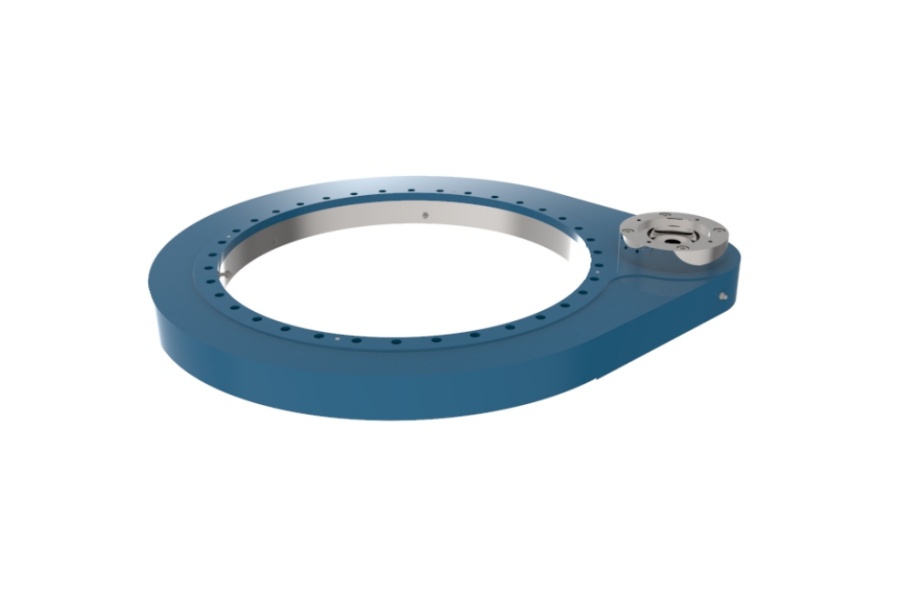

Unmatched Power & Precision: Inside the Heavy Duty Gear Slewing Drive SP-H 0655

What is the Heavy Duty Gear Slewing Drive SP-H 0655?

At its core, the SP-H 0655 is a precision-engineered mechanical assembly combining a large-diameter slewing bearing with an integrated gear mechanism and often a compact, high-torque drive system (like a worm gear or planetary gearbox). Its primary function is to facilitate the controlled, high-load rotational movement of a superstructure relative to its base. Unlike standard bearings, slewing drives transmit significant torque and simultaneously manage substantial axial, radial, and moment loads. The "Heavy Duty" designation signifies its construction using premium materials like high-grade alloy steels, advanced heat treatment processes, and robust sealing systems, enabling it to withstand extreme forces, shock loads, and challenging environmental factors like dust, moisture, and wide temperature variations encountered in mining, construction, or offshore environments. The SP-H 0655 model number denotes a specific size and configuration within a manufacturer's product line, tailored for applications requiring its particular torque output and load ratings.

The Indispensable Role in Wind Turbines: Where Reliability is Non-Negotiable

Wind turbine slewing drives are mission-critical components, directly impacting energy capture efficiency, structural integrity, and operational safety. They perform two vital functions: yaw control and pitch control. The yaw drive system rotates the entire nacelle (housing the generator and gearbox) to precisely align the rotor with the prevailing wind direction, maximizing energy generation. Pitch drives, located at the hub, adjust the angle of each individual blade to optimize aerodynamic efficiency across varying wind speeds and to feather the blades for protection during storms or shutdowns. In both roles, the SP-H 0655 class drive faces immense challenges: massive cantilevered loads from the blades and nacelle, constant exposure to unpredictable weather (salt spray, ice, humidity), relentless vibration, and the critical need for absolute reliability to prevent costly downtime or catastrophic failure. Heavy-duty slewing drives like the SP-H 0655 are engineered specifically for these extremes, featuring enhanced corrosion protection (e.g., specialized coatings), superior sealing against contaminants, high-precision gearing for smooth positioning, and robust construction to endure decades of operation with minimal maintenance.

SP-H 0655 Specifications: Engineered for Maximum Performance

The SP-H 0655 specifications define its formidable capabilities. While exact figures can vary slightly based on manufacturer optimization and specific customer requirements, typical core specifications include a very high static load capacity, often exceeding several hundred tons for combined axial, radial, and moment loads. Its dynamic load rating ensures longevity under continuous operational stresses. A key specification is its impressive output torque range, likely measured in hundreds of kNm, enabling it to rotate massive structures. The drive ratio, often involving a highly efficient worm gear mechanism, provides the necessary mechanical advantage for such high torque. Expect a large mounting diameter and height, significant weight reflecting its robust construction, and multiple bolt hole patterns for secure integration. Precision is paramount, with minimal backlash figures ensuring accurate positioning. It will feature high IP (Ingress Protection) ratings (e.g., IP66 or higher) for dust and water resistance, and potentially specific corrosion protection standards. Operating temperature ranges are broad, catering to diverse global environments. These specifications collectively define the SP-H 0655 as a powerhouse solution.

Heavy Duty Gear Slewing Drive SP-H 0655: Defining Features

Several key features distinguish the SP-H 0655 and similar heavy-duty slewing drives. Exceptional Load Capacity: Engineered with large rolling elements (balls or rollers), optimized raceway geometry, and premium hardened steels to handle extreme axial, radial, and moment loads simultaneously. Integrated Drive System: The seamless combination of the slewing bearing with a high-torque reduction gear (typically worm gear for self-locking capability) within a compact housing simplifies design and installation. Superior Sealing & Protection: Multi-labyrinth seals, often combined with grease purging systems, provide outstanding defense against water, dust, dirt, and other contaminants, crucial for longevity in harsh environments. Robust Construction: Thick-section housings, large fasteners, and reinforced structural components ensure resistance to shock loads, vibration, and structural deformation. High Precision & Low Backlash: Precision-ground gearing and meticulous assembly minimize backlash, enabling accurate positioning and smooth rotation even under heavy load. Self-Locking Capability: Worm gear designs inherently provide self-locking, holding position securely without needing a separate brake when the drive motor is disengaged. Durability & Long Service Life: Advanced materials, heat treatment, lubrication systems, and protective features are all geared towards maximizing operational lifespan and minimizing maintenance requirements. Customization Options: While a standard model, aspects like mounting flanges, gear ratios, sealing types, lubrication fittings, or surface coatings can often be tailored.

Heavy Duty Gear Slewing Drive SP-H 0655: Powering Diverse Industries

The SP-H 0655's combination of strength, precision, and reliability makes it indispensable across numerous demanding sectors. Wind Energy: As discussed, it's crucial for nacelle yaw systems and blade pitch control mechanisms in large turbines. Solar Tracking: Powers the robust rotation of large-scale Concentrated Solar Power (CSP) heliostat arrays or photovoltaic (PV) tracker systems, ensuring optimal sun alignment. Construction & Mining: Found in heavy-duty cranes (slewing upper structures), excavators (rotating house sections), tunnel boring machines, and large material handling equipment requiring reliable rotation under load. Material Handling: Used in ship-to-shore cranes, container handling cranes, stacker-reclaimers, and heavy-duty industrial robots or manipulators. Forestry Equipment: Provides the rotational force for harvesters, forwarders, and delimbers. Defense & Aerospace: Utilized in radar antenna positioning systems, missile launcher turrets, and other applications requiring precise, robust rotation. Marine & Offshore: Powers deck cranes, winches, davits, and A-frame systems on vessels and offshore platforms, demanding high corrosion resistance. Any Application requiring reliable, high-torque, high-load rotational motion benefits from the engineered solution the SP-H 0655 represents.

Factors Influencing Heavy Duty Gear Slewing Drive SP-H 0655 Pricing

The investment in an SP-H 0655 class slewing drive is significant, and its price is shaped by numerous factors. Raw Material Costs: Fluctuations in the price of high-grade alloy steels significantly impact manufacturing costs. Manufacturing Complexity: Precision machining of large components, specialized heat treatment processes (carburizing, hardening), and meticulous assembly require advanced equipment and skilled labor. Precision & Tolerances: Achieving the required low backlash and high load ratings demands extremely tight manufacturing tolerances, increasing production time and cost. Drive Mechanism: The type (worm gear, helical, planetary), size, and quality of the integrated gearing system are major cost drivers. Sealing & Protection: High IP ratings and specialized corrosion protection (e.g., offshore-grade coatings) add layers of complexity and material cost. Customization: Deviations from the standard configuration (special flanges, unique gear ratios, specific seal types, custom lubrication systems) incur additional engineering and production expenses. Quality Assurance & Testing: Rigorous quality control procedures, non-destructive testing (NDT), and performance testing protocols add to the overall cost but are essential for reliability. Volume & Order Size: Economies of scale apply; larger orders typically benefit from lower per-unit costs. Brand Reputation & Support: Established manufacturers with proven reliability and comprehensive technical support often command a premium, reflecting the value of reduced risk and downtime.

Supplier of Heavy Duty Gear Slewing Drive SP-H 0655

When sourcing a critical component like the Heavy Duty Gear Slewing Drive SP-H 0655, partnering with a reliable and experienced manufacturer is paramount. LYRADRIVE stands as a leading force in the design, engineering, and production of premium slewing drives and bearings. Leveraging cutting-edge manufacturing technology, stringent quality control processes adhering to international standards (ISO, DNV-GL, etc.), and deep engineering expertise, LYRADRIVE delivers solutions built for performance and endurance. Their focus extends beyond just supplying a product; they offer comprehensive technical support, application engineering assistance, and customization capabilities to ensure the SP-H 0655 or any slewing solution perfectly integrates into your specific machinery. LYRADRIVE's commitment to innovation, quality, and customer partnership makes them the supplier of choice for industries demanding the highest levels of reliability from their rotational drive systems. Choosing LYRADRIVE means investing in the power, precision, and longevity your heavy-duty applications demand.

The Foundation of Robust Rotation

The Heavy Duty Gear Slewing Drive SP-H 0655 embodies engineering excellence for applications where failure is not an option. Its ability to manage colossal loads while delivering precise, controlled rotation makes it the cornerstone of machinery in wind energy, heavy construction, solar power, and beyond. Understanding its specifications, appreciating its robust features, and recognizing the factors influencing its cost are crucial for making informed decisions. Partnering with a proven manufacturer like LYRADRIVE ensures access to this vital technology backed by expertise and reliability, empowering industries to build, generate, and innovate with confidence. The SP-H 0655 is not merely a component; it's the enabling force behind the smooth, powerful rotation that drives progress.