Unleash Unstoppable Power: The Heavy Duty Gear Slewing Drive Built for Extreme Demands

What is the Heavy Duty Gear Slewing Drive SP-H 0855?

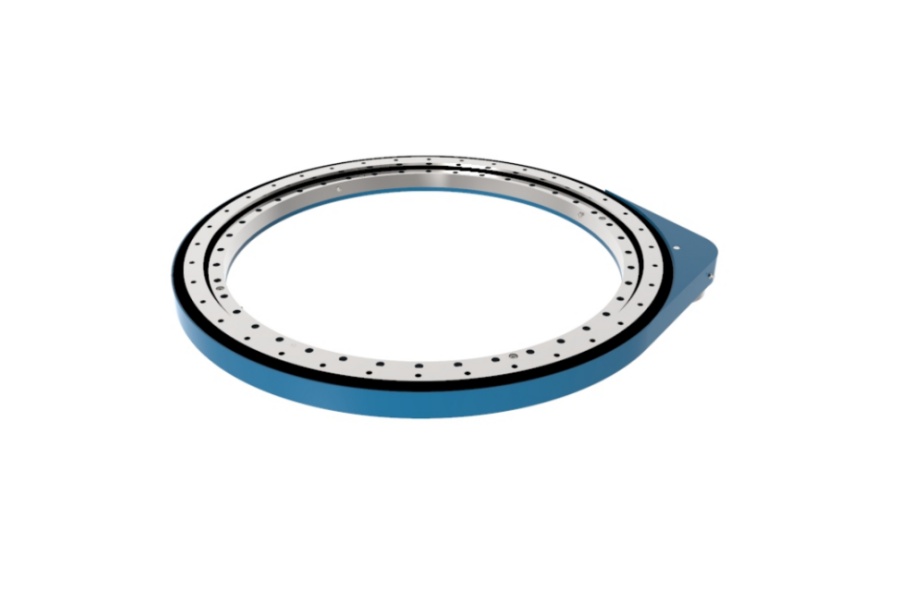

The SP-H 0855 represents a specific class of high-torque slewing drives designed for applications requiring exceptional strength, durability, and precision. Unlike standard units, it incorporates robust internal gearing – typically featuring hardened, ground helical or planetary gears – within a rigid, high-strength housing. This specific model is engineered to deliver substantial output torque while supporting significant axial, radial, and moment loads simultaneously. Its core function is to provide controlled, powerful rotational movement to large structures or machinery, translating input from a motor (electric or hydraulic) into smooth, high-torque output rotation. Built around a central slewing bearing, it integrates the bearing, gearing, housing, sealing, and often the driving motor into a compact, pre-assembled unit, simplifying installation and enhancing overall system reliability for mission-critical operations.

The Weatherproof Warrior: Why IP Ratings Are Non-Negotiable for Outdoor Slewing Drives

When slewing drives operate outdoors, they face a relentless assault from the elements – dust, grit, rain, snow, ice, and humidity. This is where Ingress Protection (IP) ratings become absolutely critical. An IP rating, defined by international standards like IEC 60529, quantifies a drive's resistance to solid particles (first digit) and liquids (second digit). For heavy-duty drives like the SP-H 0855 performing in solar farms, construction cranes, or maritime equipment, a high IP rating (typically IP65 or higher) is essential. IP65 signifies complete protection against dust ingress (ensuring abrasive particles can't damage internal gears or bearings) and protection against low-pressure water jets from any direction (safeguarding against rain, wash-downs, or snowmelt). Compromising on IP rating risks catastrophic internal corrosion, premature bearing failure, lubricant contamination, and electrical component short circuits. It directly translates to reduced maintenance costs, extended operational lifespan, and unwavering reliability, making a robust IP rating a fundamental specification, not an optional extra, for any outdoor slewing drive application.

Precision Powerhouses: High-Performance Slewing Drives Fueling Utility-Scale Solar Trackers

Utility-scale solar power plants rely on maximizing energy capture, and single-axis or dual-axis solar trackers are pivotal in achieving this. These massive structures, supporting vast arrays of solar panels, must rotate precisely to follow the sun's path throughout the day. This demands slewing drives of extraordinary capability – precisely the domain of high-performance units like the SP-H 0855. These drives must deliver immense torque to overcome wind loads and panel weight, often exceeding thousands of Newton-meters. Precision positioning is paramount to ensure optimal sun alignment for maximum energy yield. Simultaneously, they must operate with exceptional efficiency to minimize parasitic power consumption. Crucially, they endure decades of continuous, daily movement cycles under harsh environmental exposure – scorching heat, freezing cold, UV radiation, dust storms, and humidity. High-performance slewing drives are the unsung heroes, providing the robust, reliable, and precise rotational motion that allows utility-scale solar trackers to generate significantly more clean energy than fixed-tilt systems, making them indispensable for the modern renewable energy landscape.

Engineered for Extremes: Key Features of the Heavy Duty Gear Slewing Drive SP-H 0855

The SP-H 0855 distinguishes itself through a suite of features meticulously designed for heavy-duty performance:

Exceptional Torque Density: Utilizing high-precision, hardened, and ground helical or planetary gearsets within an optimized housing design, it achieves maximum torque output relative to its size, enabling it to handle massive loads efficiently.

Unmatched Load Capacity: Engineered with a robust, integrated slewing bearing featuring large diameter rolling elements, it effortlessly sustains substantial combined loads (axial, radial, and moment forces) simultaneously, ensuring stability under stress.

Superior Sealing & Protection: Equipped with high-performance seals (often multiple labyrinth and radial lip seals) and built to stringent IP65 or higher standards, it provides long-lasting defense against dust, water, and corrosive elements critical for outdoor and harsh environments.

Enhanced Durability & Long Life: Premium materials (high-grade alloy steels), advanced heat treatment processes, precision manufacturing, and optimized lubrication systems minimize wear, significantly extending service intervals and operational lifespan, even under constant heavy loads.

Precision Motion Control: Precision-ground gearing and high-rigidity construction ensure smooth, low-backlash rotation and accurate positioning, essential for applications like solar tracking or automated machinery.

Robust Housing: A rigid, often nodular iron or heavy-duty steel housing provides structural integrity, protects internal components, and offers secure mounting points, contributing to overall system stability.

Integrated Design: The pre-assembled unit combines bearing, gearing, seals, and often mounting interfaces, simplifying installation, reducing maintenance complexity, and enhancing overall system reliability.

High Efficiency: Optimized gear geometry and quality manufacturing minimize friction losses, translating motor power effectively into usable output torque while reducing operating costs.

Conquering Industrial Frontiers: Diverse Applications of the SP-H 0855

The SP-H 0855's blend of power, precision, and resilience makes it the go-to solution across numerous demanding sectors:

Utility-Scale Solar Tracking: The primary application, driving single-axis and dual-axis solar trackers for vast solar farms, ensuring precise panel alignment for maximum energy harvest under challenging environmental loads.

Heavy Machinery & Construction: Powering rotation in crawler cranes, excavator attachments, drilling rigs, concrete pumpers, and heavy-duty material handling equipment where high torque and reliability are paramount.

Wind Energy: Used in yaw drives for smaller turbines or pitch drive mechanisms, requiring precise positioning under high loads and variable weather.

Marine & Offshore: Operating deck cranes, winches, A-frames, and positioning systems on vessels and offshore platforms, demanding exceptional corrosion resistance and reliability.

Industrial Automation: Enabling precise rotational movement in large robotic arms, heavy-duty indexing tables, automated welding systems, and large-scale assembly lines.

Defense & Aerospace: Found in radar antenna positioning, missile launcher rotation, and ground support equipment requiring ruggedness and dependable performance.

Mining & Material Processing: Driving rotary feeders, large mixers, screeners, and conveyor diverters in abrasive and high-load environments.

Investment Factors: What Influences the Price of the Heavy Duty Gear Slewing Drive SP-H 0855?

The price of a high-caliber component like the SP-H 0855 is driven by several key factors reflecting its engineering and manufacturing complexity:

Materials Cost: Extensive use of high-quality, high-strength alloy steels for gears, bearings, shafts, and housing, along with specialized seals and coatings, forms a significant portion of the cost base.

Manufacturing Precision & Complexity: Achieving the required precision for hardened, ground gears and large-diameter slewing bearings involves sophisticated, capital-intensive machining processes (hobbing, grinding, turning) and rigorous quality control, adding substantial cost.

Integrated Design & Assembly: The value lies in the pre-assembled, tested unit. Integrating the bearing, gearing, seals, and often motor adapter into a compact, reliable package requires significant engineering and assembly labor.

Torque & Load Capacity: Higher torque ratings and greater load capacities necessitate larger components, more robust bearings, stronger materials, and more complex gearing, directly increasing cost.

Protection Level (IP Rating): Achieving high IP ratings (e.g., IP65, IP66, IP67) requires advanced sealing systems (multiple seals, labyrinth designs), specialized testing, and potentially specific housing features, adding to the manufacturing expense.

Customization: While the SP-H 0855 might be a standard model, variations in mounting flanges, output shaft configurations, input drive options (electric motor type, hydraulic motor interface), or specific coatings add engineering and production costs.

Quality Assurance & Testing: Comprehensive in-process and final testing protocols (load testing, backlash measurement, seal testing, run-in tests) ensure reliability but add time and resource costs.

Volume & Supply Chain: Economies of scale apply. Larger order volumes typically reduce unit cost. Fluctuations in raw material prices (steel, alloys) and component availability also impact final pricing.

Technical Support & Warranty: Reputable suppliers invest in application engineering support and offer substantial warranties, factors reflected in the product's value proposition.

Supplier of SP-H 0855 Heavy Duty Gear Slewing Drive

For engineers and project managers seeking the robust reliability and power of the SP-H 0855 Heavy Duty Gear Slewing Drive, LYRADRIVE stands as a premier supplier. We specialize in the design, engineering, and manufacturing of high-performance slewing drives tailored for the most demanding applications, particularly in renewable energy and heavy industry. Choosing LYRADRIVE means partnering with experts who deeply understand the challenges of torque, load, and environmental extremes. Our commitment extends beyond delivering a component; we provide engineered solutions backed by rigorous in-house testing, stringent quality control processes adhering to international standards, and comprehensive technical support throughout your project lifecycle. We leverage advanced manufacturing capabilities and premium materials to ensure every SP-H 0855 drive meets exacting specifications for durability, efficiency, and precision. Whether you require standard configurations or application-specific modifications, LYRADRIVE offers the engineering expertise and manufacturing excellence to be your trusted partner for critical motion solutions. Experience the difference of performance engineered for the long haul.