Unlocking Multi-Ton Rotational Power: An In-Depth Look at Worm Gear Slew Drives

What is a Worm Gear Slew Drive?

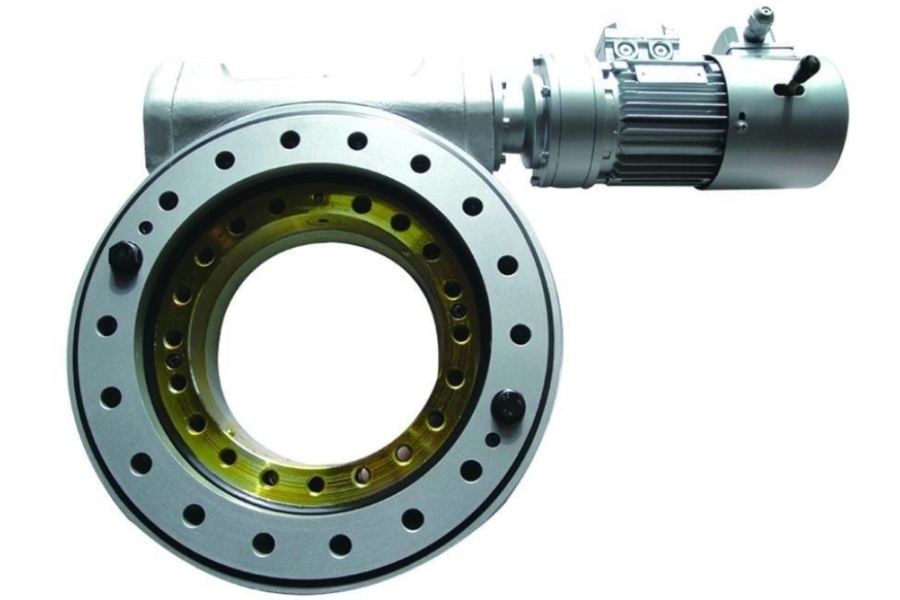

A worm gear slew drive is a compact rotational transmission device. Its core consists of a worm shaft (input shaft) and a worm wheel (output gear ring). When the motor drives the worm shaft to rotate, the threads on the worm shaft push against the teeth on the worm wheel, causing it to turn slowly. This design achieves an extremely high reduction ratio and output torque. The worm shaft is typically made of hardened steel, while the worm wheel often uses wear-resistant bronze or special cast iron.

The Secret to High Torque Output

The core advantage of worm gear transmission is high torque. The sliding contact between the worm shaft and the worm wheel teeth creates significant mechanical advantage. Even with relatively small input power, it can produce astonishing rotational force. This allows worm gear slew drives to effortlessly carry multi-ton loads and rotate stably. Their exceptional start-stop control capability makes them particularly suitable for heavy equipment requiring precise positioning.

Core Components And Working Principle

The precise operation of a worm gear slew drive relies on several key components:

Worm Shaft & Worm Wheel: The core transmission pair, achieving a large reduction ratio and high torque.

Robust Housing: Typically made of high-strength cast iron or steel, it supports all components and resists deformation and impact.

Bearing System: Large roller or tapered roller bearings that withstand enormous radial, axial, and overturning moments.

Sealing System: Multiple seals prevent external contaminants from entering and keep internal lubricant clean.

Lubrication System: Ensures the worm gear mesh surfaces and bearings receive adequate lubrication, reducing wear.

The motor drives the worm shaft to rotate. The worm shaft threads engage with the worm wheel teeth, generating sliding friction. This friction drives the worm wheel and the connected platform to rotate slowly and powerfully.

Maintenance of Worm Gear Slew Drive: Key to Ensuring Long-Term Operation

Regular maintenance is crucial for worm gear slew drives:

Lubrication Management: Regularly check and replace the lubricating grease according to the manufacturer's specifications regarding type and viscosity. Contaminated or degraded grease is a primary cause of failure.

Seal Inspection: Ensure seals are intact and undamaged to prevent water, dust, or abrasive particles from entering the interior.

Tooth Surface Inspection: Periodically inspect the meshing surfaces of the worm and wheel for wear. Early detection of problems prevents catastrophic failure.

Bolt Tightening: Regularly check that the tightening torque of mounting bolts and critical internal fasteners meets specifications.

Reliability And Service Life

Worm gear slew drives are renowned for high reliability. They are designed from the outset to withstand extreme loads and harsh environments. Service life depends on several factors: load spectrum, maintenance frequency, environmental conditions, and initial design margin. Selecting high-quality materials, precision manufacturing, and strictly adhering to the maintenance plan can significantly extend their service life to decades. The key lies in controlling wear and maintaining good lubrication.

Distinctive Features of Worm Gear Slew Drives

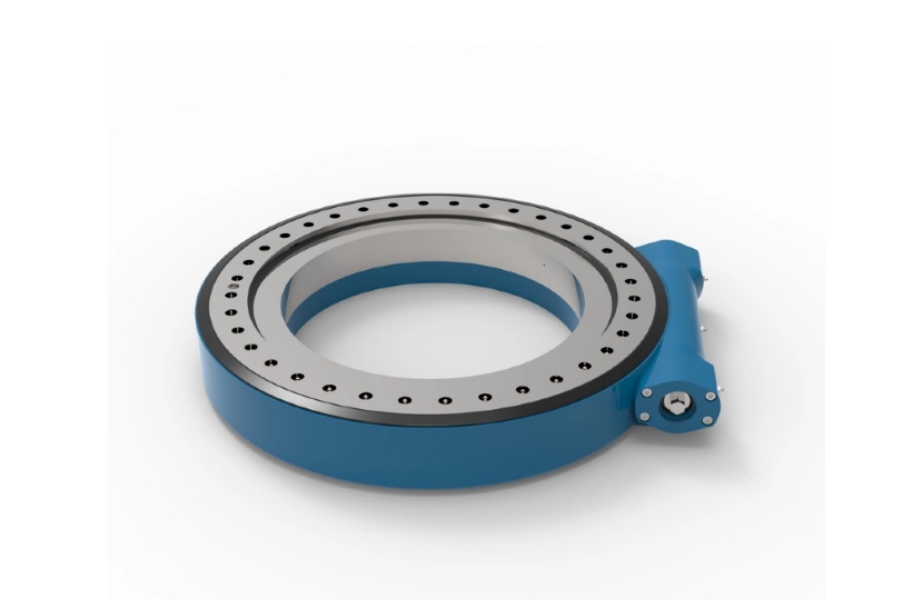

Excellent Self-Locking Capability: The worm lead angle design allows it to naturally lock the load without power input, eliminating the need for an additional brake.

Ultra-High Reduction Ratio: A single stage can achieve a very large reduction, resulting in an extremely compact structure.

Smooth & Quiet Operation: The sliding contact transmission method is quieter and smoother running compared to gear transmissions.

High Impact Resistance: Robust design and sliding mesh characteristics enable it to withstand severe shock loads.

Precise Positioning Ability: Low backlash design enables accurate rotational angle control.

Wide Range of Applications

Worm gear slew drives are ubiquitous wherever powerful, reliable rotational force is needed:

Solar Power: Driving solar PV panels or collectors to accurately track the sun's path.

Construction Machinery: Superstructure slewing platforms on cranes, excavators, concrete pump trucks.

Wind Power: Pitch and yaw systems (in some designs).

Heavy Equipment: Port cranes, marine cranes, radar antenna pedestals, TBM cutterhead drives.

Material Handling: Large stacker-reclaimers, rotary kilns.

Military & Aerospace: Radar, satellite communication antennas, missile launchers.

Factors Influencing Price

The price of worm gear slew drives varies significantly, primarily driven by:

Torque & Size Requirements: The larger the torque output required, the larger the drive size, naturally increasing material usage and machining costs.

Material Grade: Whether the worm wheel uses high-strength bronze or standard cast iron, and whether the worm shaft uses premium alloy steel with deep hardening, directly impacts cost and lifespan.

Manufacturing Precision: High-precision grinding of the worm and wheel significantly reduces backlash and improves efficiency but involves complex, costly processes.

Bearing Grade & Configuration: Using top-tier brand large bearings or custom bearing combinations substantially increases cost.

Sealing & Protection Rating: Special seal designs required for extreme environments (e.g., IP67/IP69K) or explosion-proof requirements add cost.

Customization Level: Standard products are lower cost. Custom flanges, shaft sizes, lubrication systems, or mounting configurations significantly increase engineering and manufacturing costs.

Brand & Origin: Well-known brands and manufacturing in Europe, the US, or Japan typically imply higher quality standards and price.

Purchase Quantity: Bulk purchases usually secure better unit pricing.

Supplier of Worm gear slew drives

Worm gear slew drives perfectly combine immense power with precise control. Their high torque, self-locking capability, and reliability make them the ideal choice for heavy-duty rotational applications. Understanding their principles, maintenance essentials, and value-influencing factors is key to selecting the optimal drive solution. Seeking the power core for your heavy-duty rotation needs? Contact us LYRADRIVE now for professional worm gear slew drive solutions.