Unlock Unprecedented Torque Density: Mastering Motion with the Enveloping Slewing Drive SE5

What is the Enveloping Slewing Drive SE5?

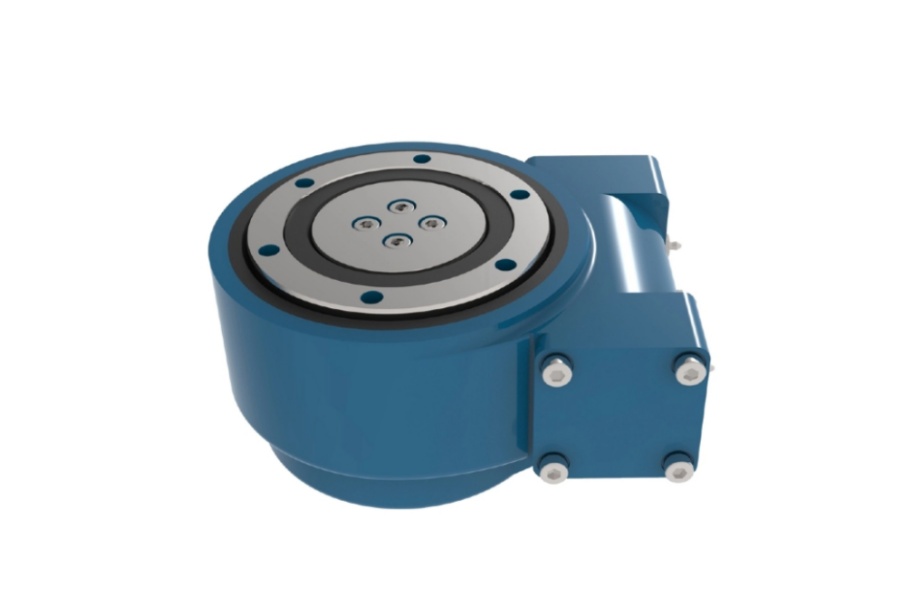

The Enveloping Slewing Drive SE5 represents a significant advancement in slewing drive technology, characterized primarily by its enveloping worm gear design. Unlike standard cylindrical worms, the worm in the SE5 partially or fully "envelops" the worm wheel (gear). This intricate geometry creates significantly more contact area between the worm threads and the gear teeth. The result is a dramatic increase in torque transmission capability, superior load distribution across the gear teeth, enhanced rigidity minimizing deflection under heavy loads, and smoother, quieter operation even at high loads. This enveloping action is the core innovation that defines the SE5 series and sets it apart, allowing it to handle immense moment loads and axial/radial forces within a surprisingly compact envelope. It's engineered for applications demanding maximum power density and reliability.

The Low Profile Slewing Drive Compromise

Low profile slewing drives prioritize minimizing the overall height (axial dimension) of the unit. This is crucial for applications with strict vertical space limitations, such as certain satellite communication antennas, deck machinery on ships, or equipment needing to fit under low clearances. While achieving a slim design, low profile drives often face inherent trade-offs. Reducing height typically means using bearings with smaller cross-sections or modified gear geometries, which can limit their overall load capacity, particularly concerning moment (overturning) loads and rigidity compared to taller designs. They might also have constraints on gear ratio options or maximum input speeds due to the compact gearing arrangement. Low profile drives excel where space is the absolute primary constraint, but they may not deliver the raw power and stiffness of designs like the SE5.

The Enveloping Advantage: Why the SE5 Stands Out

Returning to the SE5, its enveloping worm design is not merely a feature; it's the fundamental reason for its superior performance. By wrapping around the worm wheel, the worm engages more teeth simultaneously and across a broader surface area. This distributes the immense forces generated during operation over a much larger contact patch, drastically reducing localized stress and wear. Consequently, the SE5 achieves torque densities far exceeding those possible with standard single-enveloping or non-enveloping worm drives of similar physical size. The increased rigidity inherent in this design minimizes unwanted deflection or backlash under heavy or dynamic loads, ensuring precise positional accuracy and repeatability. This combination of high torque, exceptional rigidity, inherent self-locking capability (due to the worm angle), and compact footprint is the hallmark of the SE5 enveloping slewing drive.

The Compact Slewing Drive Landscape

Compact slewing drives focus on minimizing the overall footprint and weight of the drive unit while still delivering essential performance. This is vital for mobile applications, robotics, medical equipment, or any scenario where weight savings and space optimization are critical. Compact designs achieve this through efficient packaging, potentially using lighter materials, optimized bearing arrangements, and advanced manufacturing techniques. They offer a good balance of performance and size for many applications. However, "compact" often implies inherent limitations in maximum achievable torque and load capacity compared to larger, more robust units like the SE5. While highly space-efficient, compact drives might reach their performance ceiling faster when faced with extreme loads or the need for maximum rigidity. They represent a different point on the performance-spectrum versus size spectrum compared to the power-focused SE5.

The Pinnacle of Power Density: The Enveloping Slewing Drive SE5

The Enveloping Slewing Drive SE5 transcends the typical compact category by delivering exceptional torque and load capacity within a compact form factor, thanks solely to its enveloping worm technology. It doesn't just save space; it packs an extraordinary amount of power into that space. Where a standard compact drive might suffice for moderate loads, the SE5 steps in when those loads become severe, when moment forces are extreme, or when absolute minimal deflection is non-negotiable, all without requiring a physically massive solution. It bridges the gap where both high power and space constraints coexist, offering a solution that neither standard compact drives nor bulky traditional gearboxes can match as effectively. The SE5 is engineered for the most demanding compact applications.

Key Features of the Enveloping Slewing Drive SE5

The Enveloping Slewing Drive SE5 boasts a suite of features engineered for peak performance and reliability. Its defining enveloping worm gearset delivers unmatched torque density and rigidity, directly translating to higher load capacities in all directions. This robust construction ensures exceptional durability and a long operational lifespan, even under harsh conditions. The drive exhibits minimal backlash due to the precise meshing of the enveloping components, guaranteeing high positional accuracy essential for precision tasks. Integral seals provide effective protection against dust, dirt, and moisture ingress, enhancing reliability. The inherent self-locking characteristic of the worm gear design prevents back-driving under load, adding safety and stability without needing an external brake in many scenarios. Multiple mounting configurations offer flexibility for integration into diverse machinery layouts. High-efficiency variants minimize power loss and heat generation. Finally, LYRADRIVE offers extensive customization options for the SE5, including specific mounting patterns, special seals, lubrication, input shaft configurations, and custom gear ratios, ensuring a perfect fit for the application.

Diverse Applications Demanding SE5 Performance

The unique capabilities of the Enveloping Slewing Drive SE5 make it indispensable across numerous demanding industries. In solar energy, it's the preferred drive for large, single-axis and dual-axis solar trackers, where high torque is needed to rotate massive panel arrays against wind loads, and rigidity is critical for maintaining precise sun alignment. Heavy construction and material handling rely on SE5 drives for robust crane jib rotation, efficient conveyor swing mechanisms, and precise positioning of excavator attachments. Within renewable energy, it powers the yaw and pitch control mechanisms of wind turbines, handling enormous inertial loads and ensuring optimal blade angle. Radar and satellite communication systems utilize the SE5 for highly accurate antenna positioning where signal integrity depends on minimal deflection. Industrial automation leverages its precision and power for robotic welding positioners, heavy-duty indexing tables, and automated assembly lines. Specialized applications include artillery turrets, medical imaging equipment rotation stages, stage machinery for precise movement of heavy sets, and sophisticated test rigs requiring high torque and rigidity. Essentially, any application needing reliable, high-torque rotary motion in a compact package under significant loads benefits from the SE5.

Factors Influencing Enveloping Slewing Drive SE5 Pricing

The price of an Enveloping Slewing Drive SE5 is influenced by several key factors. Material selection significantly impacts cost, with high-grade alloy steels for gears and bearings, specialized hardening processes, and premium sealing materials commanding higher prices than standard alternatives. The size and torque rating of the specific SE5 model are fundamental; larger drives designed for higher torque and moment loads naturally require more material and sophisticated manufacturing, increasing cost. The level of customization required plays a major role; standard catalog units are more economical, while modifications like special mounting flanges, unique input shafts, custom gear ratios, or application-specific coatings add expense. Bearing specifications within the slewing ring are critical; higher precision classes, enhanced sealing, or special bearing types (like cross roller bearings) increase the unit cost. Gear manufacturing precision, especially for the complex enveloping worm profile, demands advanced machining and quality control, contributing to the cost structure. Order quantity affects unit price, with volume production typically offering economies of scale. Finally, market dynamics, including raw material costs and overall manufacturing overhead, also influence the final price point of the SE5 drive.

Supplier of Enveloping Slewing Drive SE5

The Enveloping Slewing Drive SE5 is not just another gearbox; it's a meticulously engineered solution for the most challenging rotary motion problems. Its defining enveloping worm gearset unlocks unparalleled torque density and rigidity within a remarkably compact form factor. This technology sets it apart from standard low-profile or compact drives, which often sacrifice ultimate power for size or vice versa. The SE5 delivers where others cannot: handling extreme moment loads, ensuring pinpoint accuracy under stress, and providing reliable, long-lasting performance in demanding environments like solar tracking, heavy machinery, wind energy, and precision automation. While factors like materials, size, customization, and bearing specs influence its price, the value proposition of the SE5 lies in its ability to solve complex motion challenges efficiently and reliably. When peak performance, unwavering rigidity, and space efficiency are non-negotiable, the Enveloping Slewing Drive SE5 from LYRADRIVE provides the definitive engineered edge. It empowers designers and engineers to push the boundaries of what's possible in rotary motion control.