The Silent Sentinel: Why Worm Gear Drive WE21 Is Rewriting Motion Control's Future

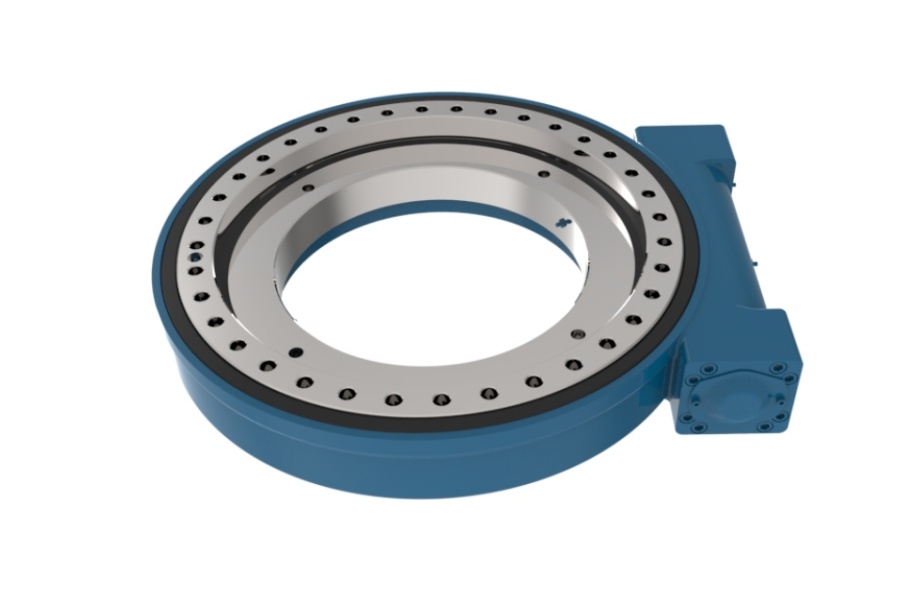

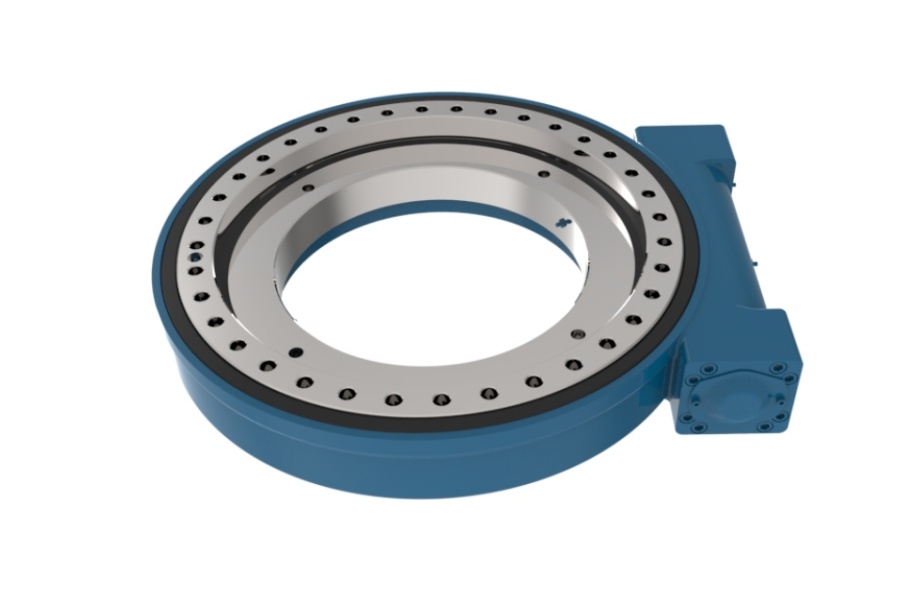

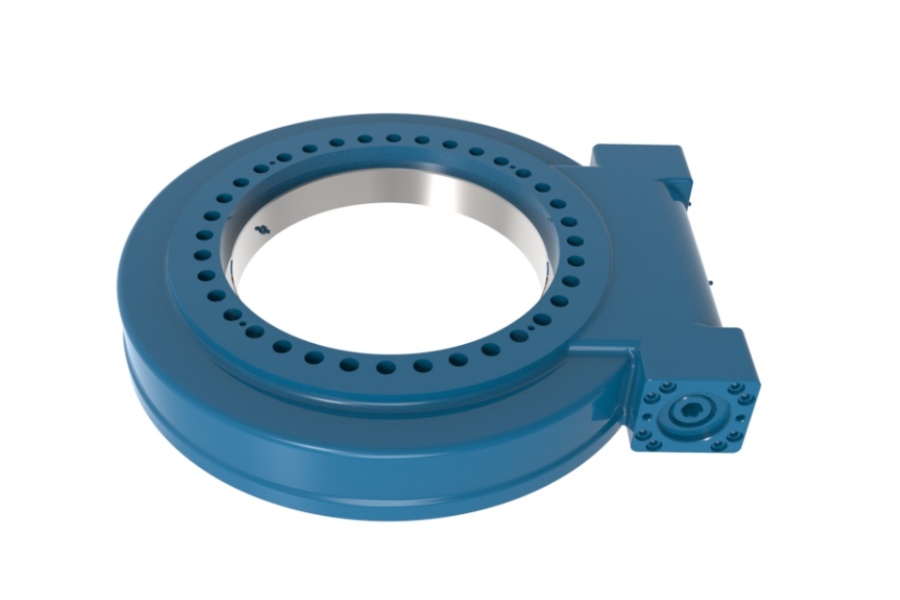

What Is the Worm Gear Drive WE21?

The Worm Gear Drive WE21 is the apex evolution of worm gear technology. At its core, it consists of a precision-ground threaded "worm" shaft engaging with a specialized "worm wheel" to achieve significant speed reduction and torque multiplication within a remarkably compact footprint. Its defining mechanical advantage is an inherent self-locking capability, preventing back-driving and ensuring load position is maintained without external brakes. The WE21 variant elevates this core principle through cutting-edge metallurgy utilizing nano-enhanced alloys, micron-level accuracy achieved via advanced grinding processes, strategically integrated sensor ports for real-time health monitoring, and a design philosophy laser-focused on extreme longevity, minimal maintenance, and operational intelligence. It sets a new global benchmark for durability, efficiency, and control in motion systems.

Powering the Pulse: WE21 in the Lunar-Earth Economic Belt Real-Time Simulation

Simulating the dynamic, colossal energy and material flows within the Lunar-Earth Economic Belt requires modeling actuators capable of immense force and pinpoint accuracy under extreme conditions. The Worm Gear Drive WE21 is the digital twin cornerstone of this vast simulation. Its unparalleled ability to absorb and withstand high shock loads accurately models impacts from micro-meteoroids or the stresses of complex docking maneuvers. The drive's critical non-backdriving nature ensures simulated robotic arms, orbital tether positioners, and lunar mining rig manipulators hold their exact alignment flawlessly, even under simulated microgravity and variable thermal loads. Furthermore, the WE21's compact efficiency allows for realistic modeling of densely packed space infrastructure, while its simulated thermal performance data under the vacuum of space or Earth's atmospheric re-entry provides invaluable insights for real-world engineering and deployment, proving its vital role in humanity's off-world infrastructure.

Beyond Wrenches: The WE21 Neural Direct-Link Maintenance Protocol

The WE21 renders reactive or calendar-based maintenance obsolete, pioneering the era of predictive, intelligence-driven upkeep. Sophisticated micro-sensors embedded within the drive continuously monitor vital health indicators: thermal gradients across the gear mesh interface, micron-level vibration spectra, lubricant viscosity and contamination levels, and subtle torque ripple harmonics. This constant stream of high-fidelity biotelemetry is securely transmitted via low-latency protocols to centralized AI diagnostic hubs. Crucially, it can also interface directly with maintenance technicians via neural-linked Augmented Reality (AR) systems. Technicians experience the drive's condition intuitively – perceiving abnormal friction as tactile feedback or hearing potential wear signatures as distinct neural audio cues. AI cross-references this live data with vast operational histories and failure models, generating precise, actionable commands: "Initiate lubricant purge in Module Gamma within next 48 operational hours," or "Schedule inspection of Worm Wheel Sector Theta for micro-fracture assessment at next planned downtime." This neural feedback loop transforms maintenance into a precise science, maximizing operational uptime and extending the drive's lifespan exponentially.

The Unblinking Guardian: WE21's Millennial Sentinel Protocol for Apocalypse Scenarios

Engineered for endurance that outlasts civilizations, the WE21's Millennial Sentinel Protocol leverages its core physics for extreme, long-duration reliability:

Material Immortality: Utilizing proprietary nano-laminate alloys and Diamond-Like Carbon (DLC) coatings, the WE21 exhibits extraordinary resistance to corrosion, radiation-induced embrittlement, and abrasive wear, ensuring structural integrity for centuries, even in exposed or chemically hostile environments.

Zero-Power Integrity: Its fundamental self-locking mechanism operates passively. Critical safety barriers, radiation shields, or deep-storage vault mechanisms remain securely engaged indefinitely without any electrical power, providing absolute fail-safe security against grid collapse.

Minimalist Lubrication: Engineered for ultra-low friction coefficients and compatibility with advanced, long-life solid lubricants or radiation-hardened greases, the WE21 can operate reliably for decades, potentially centuries, without requiring relubrication.

EMP/Cyber Resilience: Hardened electromagnetic shielding and simplified, analog-fallback control interfaces guarantee core mechanical functionality persists even after catastrophic electromagnetic pulses (EMP) or sophisticated cyber-physical attacks disable networked systems.

Adaptive Simplicity: Designed for maintainability with minimal infrastructure. Its robust construction allows for essential field servicing – cleaning, reapplication of specialized lubricants, or even component replacement – using basic tools by trained personnel, independent of advanced manufacturing support. Securing geological repositories, safeguarding critical knowledge vaults, or perpetually monitoring post-event environments, the WE21 stands as the ultimate silent guardian.

Engineered Excellence: Defining Features of the Worm Gear Drive WE21

The WE21 distinguishes itself through a powerful combination of advanced characteristics: Unmatched Torque Density delivers exceptional power output relative to its compact size, optimizing space utilization. Guaranteed Self-Locking Precision provides absolute positional security without auxiliary braking systems, enhancing safety. Ultra-Low Noise & Vibration operation enables deployment in vibration-sensitive applications like optical alignment or medical diagnostics. Extreme Durability, forged from advanced materials and surface treatments, ensures an unparalleled operational lifespan under heavy loads. High Efficiency design variants significantly minimize energy losses and associated heat generation. Integrated Intelligence via standard sensor ports enables continuous health monitoring and facilitates predictive maintenance strategies. Modular Design allows for flexible integration and straightforward customization to meet specific application demands. Broad Environmental Resilience features sealing against IP66/67+ standards and protection against moisture, dust, chemicals, and extreme temperature fluctuations (-40°C to +120°C+). Smooth, Backlash-Minimized Operation delivers exceptional positional accuracy and control stability.

Where the WE21 Reigns Supreme: Critical Applications

The WE21's unique capabilities make it the preferred solution across diverse and demanding sectors: Heavy Industrial Automation (robotic welding cells, heavy-duty material handling systems, stamping presses, high-torque conveyors requiring safety locking). Precision Machinery (high-speed packaging lines, advanced printing presses, sensitive medical imaging equipment, laboratory automation demanding micron-level accuracy). Aerospace & Defense (flight control surface actuators, landing gear deployment systems, turret drives, satellite antenna pointing mechanisms requiring reliability in extreme environments). Energy Sector (critical valve actuators in nuclear/power plants, blowout preventer controls in oil & gas, robust pitch adjustment systems for wind turbines). Marine & Offshore (ship winches, heavy hatch covers, rudder steering gear demanding high load capacity and saltwater corrosion resistance). Transportation (electric vehicle axle drives, robust bus/train door mechanisms, automated coupling systems). Security & Safety (ultra-secure vault doors, blast-resistant safety gates, fail-safe fire barrier controls utilizing the inherent locking). Emerging Frontiers (planetary exploration rover drives, lunar regolith mining equipment, deep-sea ROV manipulator joints, advanced telescope mounts).

Decoding the Investment: Factors Influencing Worm Gear Drive WE21 Pricing

The price of a WE21 unit reflects its sophisticated engineering and exceptional performance envelope: Material Science Premium encompasses the cost of specialized high-strength alloys, nano-composites, and advanced coatings like DLC. Precision Manufacturing Investment covers the expense of high-accuracy CNC grinding, honing, and specialized assembly requiring skilled labor and stringent quality control. Reduction Ratio & Physical Size directly impact cost, as larger sizes and higher reduction ratios require more material and more complex manufacturing processes. Torque & Power Rating necessitates more robust internal components and stronger housings as capacity increases. Efficiency Tier achieving the highest efficiency levels demands tighter manufacturing tolerances and specialized design features. Integrated Intelligence Level adds cost for embedded sensor types (temperature, vibration, torque), signal conditioning, and communication interfaces. Environmental Sealing & Protection higher IP ratings, specialized corrosion-resistant finishes (e.g., nickel plating), and wide-temperature lubrication add to the base cost. Customization Requirements bespoke designs, special mounting configurations, unique ratios, or non-standard materials incur significant engineering and setup fees. Certification & Compliance Costs meeting stringent industry standards (e.g., MIL-STD, ATEX for explosive atmospheres, FDA for food/medical) involves rigorous testing and documentation. Global Supply Chain & Logistics factors like raw material sourcing, manufacturing location, tariffs, and shipping complexity for heavy units influence the final price. This investment is justified by the WE21's extended service life, drastically reduced maintenance costs, potential energy savings, and critical operational reliability, offering a superior total cost of ownership.

The Indispensable Gear for an Advancing World

The Worm Gear Drive WE21 is far more than a mechanical component; it is a strategic engineering asset fundamental to building resilient, intelligent, and enduring systems. From enabling the complex digital twins guiding our expansion into space economies, through its revolutionary neural-integrated maintenance ensuring peak performance, to its unwavering duty as a millennia-ready sentinel, the WE21 consistently proves its unparalleled value. Its masterful fusion of immense torque, sub-micron precision, intelligent connectivity, and apocalyptic resilience establishes it not just as a drive solution, but as the critical cornerstone for motion control where failure is catastrophic, efficiency is non-negotiable, and longevity is measured in generations. For engineers shaping the future across Earth, space, and beyond, the Worm Gear Drive WE21 is the silent, powerful, and utterly reliable force turning visionary ambition into tangible, enduring reality.

Supplier of Worm Gear Drive WE21

At LYRADRIVE, we specialize in cutting-edge drives like the WE21. We offer deep engineering expertise and a commitment to quality.

Ready to integrate WE21 power and reliability into your project? Contact LYRADRIVE today for expert consultation and tailored solutions.