Troubleshooting Noise Issues in Double Worm Slew Drives

What is a Double Worm Slew Drive?

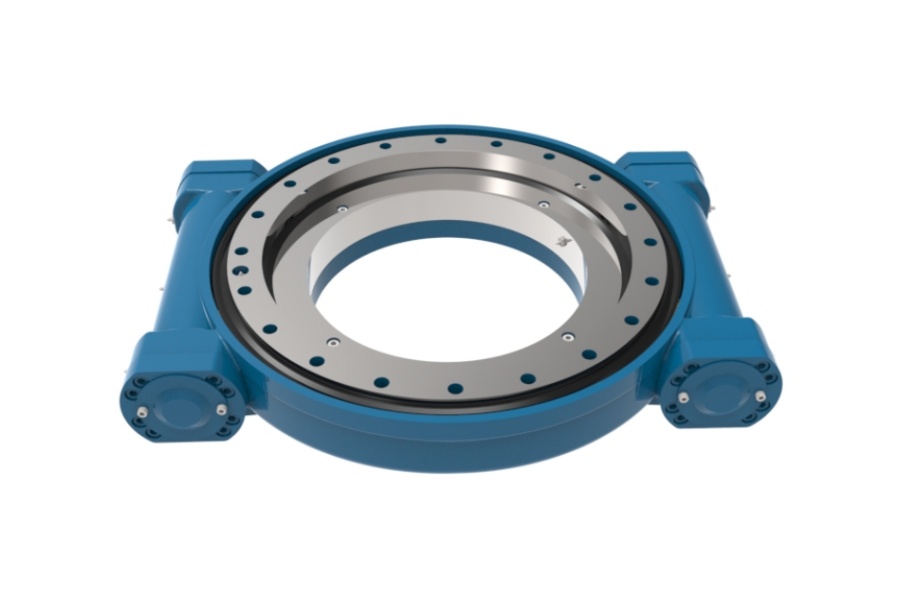

Double Worm Slew Drive represents a highly engineered type of rotational actuator. At its core, it integrates a large-diameter slewing bearing (or turntable bearing) capable of handling significant axial, radial, and moment loads. The defining characteristic is its dual-worm gear drive mechanism. Two parallel worm shafts engage with a single, large gear ring (typically the outer ring of the slewing bearing). This configuration transmits torque from the input motors (usually electric) through the worms to the gear ring, resulting in precise, controlled rotation of the attached structure relative to the base. The primary function is to provide robust, reliable rotational motion under heavy loads with inherent self-locking capabilities in many configurations, making them indispensable in demanding industrial applications like solar trackers, cranes, and heavy machinery.

Reasons for Noise Generation in Slew Drives and Handling Methods

Noise emanating from a slewing drive during operation is a critical indicator of potential issues. Primarily originating from the gear mesh points or within the slewing bearing itself, identifying the root cause is essential for effective resolution. Design engineers commonly attribute operational noise to the following key areas:

Lubrication-Related Noise: Proper lubrication is paramount. Manufacturers like LYRADRIVE typically pre-lubricate drives with high-quality grease, such as Mobil EP2 for standard temperatures (-10°C to 40°C). For extreme environments (-40°C to 150°C), specialized greases like Mobil XHP 222 are recommended. Cause: Noise and irregular vibration often arise from insufficient lubricant, incorrect lubricant selection for the operating conditions, or lubricant degradation/hardening over time. Handling: The solution requires selecting the precise lubricant specified for the application's temperature, load, and speed. Ensure lubrication points are fully charged according to the manufacturer's schedule. Implement a proactive maintenance plan to monitor lubricant condition and adhere strictly to recommended replacement intervals to prevent aging and hardening. Re-lubricating with the correct grease often resolves this noise.

Noise Caused by Contaminant Ingress: Slewing drives rely on robust sealing systems (commonly Nitrile Rubber - NBR) installed at critical points like the slewing bearing raceways and interfaces between the bearing and housing to exclude contaminants (dust, metal chips, water). Cause: Noise and damage occur when seals age, become damaged, or fail, creating gaps. This allows contaminants to enter the internal gear mesh and bearing raceways, causing abrasive wear, pitting, and ultimately, increased noise and vibration. Lubricant leakage often accompanies this failure. Handling: Regularly inspect all seals for signs of wear, cracking, or damage. Replace seals promptly using materials compatible with the specific operating environment (e.g., Viton for high temp/chemicals). Ensure sealing surfaces are clean and undamaged during reassembly. Maintaining seal integrity is crucial for preventing contamination-induced noise and premature failure.

Noise Due to Mounting Surface Irregularities or Loose Fasteners: Slewing drives are precision-machined components designed with strict tolerances for mounting surface flatness. Cause: Significant noise problems arise if the mounting surface on the customer's base structure is uneven. This warps the drive housing, inducing misalignment. This misalignment forces the slewing bearing into an unnatural state, creating negative clearance (preload) in the raceways and disrupting the optimal worm-gear mesh, leading to binding, increased friction, and characteristic noise. Similarly, loose mounting bolts allow the drive to shift or partially lift under load, causing elastic deformation in the slewing bearing structure. This deformation also creates localized negative clearance and misalignment, resulting in operational noise. Handling: Before installation, meticulously check the mounting surface flatness using precision straightedges or levels against the drive manufacturer's specifications. Correct any significant deviations through machining or shimming. Ensure the mounting surface is clean, flat, and rigid. During installation, tighten all mounting bolts evenly and progressively in a cross-pattern to the specified torque using a calibrated torque wrench. Implement a regular maintenance schedule to re-check and re-torque all mounting bolts, as they can loosen due to operational vibrations and load cycles. Proper mounting is fundamental to quiet and reliable operation.

Key Characteristics of Double Worm Slew Drives

Double Worm Slew Drives offer distinct advantages that make them suitable for heavy-duty applications:

Enhanced Load Distribution & Rigidity: The dual-worm design inherently shares the load between two contact points on the gear ring. This significantly increases the drive's moment load capacity and overall rigidity compared to single-worm designs, making it ideal for applications with high overturning moments or dynamic loads.

Redundancy and Safety: The presence of two independent worm drives provides a level of redundancy. Should one worm or motor fail (depending on the control system design), the other can often maintain controlled motion or hold the load securely, enhancing operational safety.

Superior Backdrive Resistance / Self-Locking: The double worm configuration typically offers very high mechanical efficiency in the driving direction while maintaining excellent resistance to backdriving (especially when not powered). This inherent self-locking characteristic is crucial for safety in applications like cranes or lifts where unintended movement must be prevented.

High Precision and Smoothness: Precision machining of the worms and gear ring, combined with optimal preload settings, allows for very smooth rotation and high positional accuracy, which is essential in applications like radar antennas or telescope positioning.

Compact Design for High Torque: Despite their high torque output and load capacity, Double Worm Drives offer a relatively compact solution compared to achieving similar performance with multiple single drives or larger alternative mechanisms.

Typical Applications of Double Worm Slew Drives

The unique blend of high load capacity, rigidity, precision, and safety features makes Double Worm Slew Drives the preferred choice in numerous demanding sectors:

Solar Energy: Dominating large-scale solar photovoltaic (PV) tracking systems (single-axis and dual-axis), where they reliably rotate massive panel arrays under wind and snow loads, ensuring optimal sun alignment.

Heavy Construction Machinery: Found in crawler crane upper structures (slewing), excavator attachments requiring precise rotation, drilling rig masts, and heavy-duty material handling equipment.

Wind Energy: Used in yaw drives (positioning the nacelle) and pitch drives (adjusting blade angle) of wind turbines, where reliability under extreme loads and conditions is paramount.

Industrial Automation & Robotics: Employed in heavy-duty robotic arms, large indexing tables, automated welding positioners, and other machinery requiring robust, precise rotational movement.

Defense & Aerospace: Utilized in radar antenna positioning systems, satellite communication dishes, missile launcher platforms, and turret systems requiring high accuracy and reliability.

Material Handling: Integral to large stacker-reclaimers in bulk handling, heavy-duty turntables, and specialized lifting/positioning equipment.

Factors Influencing Double Worm Slew Drive Pricing

The cost of a Double Worm Slew Drive is not a simple figure and varies significantly based on several critical engineering and commercial factors:

Size and Load Capacity: The physical dimensions (gear ring diameter being a primary driver) and the required load ratings (axial, radial, moment loads) are fundamental cost factors. Larger drives built to handle immense forces require significantly more material and complex manufacturing processes.

Gear Quality and Precision: The manufacturing precision (e.g., AGMA quality class, DIN standards), tooth profile, surface finish, and heat treatment of the worms and gear ring dramatically impact performance, longevity, noise levels, and cost. Higher precision gears demand more sophisticated machining and quality control.

Slewing Bearing Specifications: The type (crossed roller, ball, three-row roller), size, internal clearance/preload, raceway hardness, and seal quality of the integrated slewing bearing are major cost components. Bearings designed for higher dynamic loads or extreme environments cost more.

Materials: The grade of steel used for gears, worms, housings, and the slewing bearing components (including specialized alloys or coatings for corrosion resistance or extreme wear) influences both performance and price.

Drive Configuration: Options like integrated hydraulic motors versus electric motors, the inclusion of brakes, specific sealing requirements (IP rating), special coatings (e.g., corrosion protection), custom mounting interfaces, and sensor integration (encoders, temperature) all add to the unit cost.

Manufacturing Volume and Customization: Standard catalog drives produced in higher volumes benefit from economies of scale, reducing per-unit cost. Highly customized drives tailored to specific applications involve significant engineering and setup costs, leading to higher prices.

Brand Reputation and Quality Assurance: Established manufacturers with rigorous quality control systems (ISO certifications), extensive testing protocols, proven reliability, and strong technical support typically command a price premium over lesser-known suppliers.

Supplier of Double Worm Slew Drive

LYRADRIVE is a recognized manufacturer specializing in the design and production of high-performance slewing drives, including advanced Double Worm Slew Drive solutions. They focus on engineering robust drives capable of meeting the stringent demands of heavy industrial applications like solar tracking, construction machinery, and material handling. LYRADRIVE emphasizes quality manufacturing processes, material selection, and rigorous testing to ensure reliability and longevity in challenging operating environments. Their product range typically includes options designed to handle significant axial, radial, and moment loads while offering configurations tailored to specific customer requirements, supported by technical expertise. For detailed specifications and application support, consulting directly with LYRADRIVE's engineering team is recommended.