Spur Gear and Worm Gear Slew Drives Key Application Domains

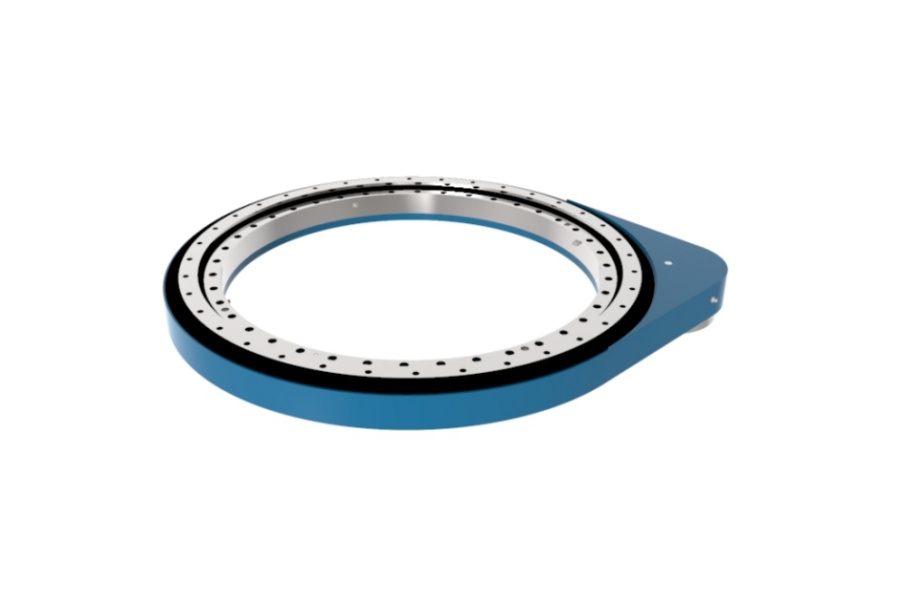

What is Spur Gear Slew Drive

Spur Gear Slew Drive integrates straight-tooth gearing with a slewing bearing to deliver high-efficiency rotational motion. These systems convert motor input into high-torque output while maintaining 95-98% energy efficiency. Their bidirectional operation capability makes them ideal for applications requiring rapid positioning and frequent direction changes.

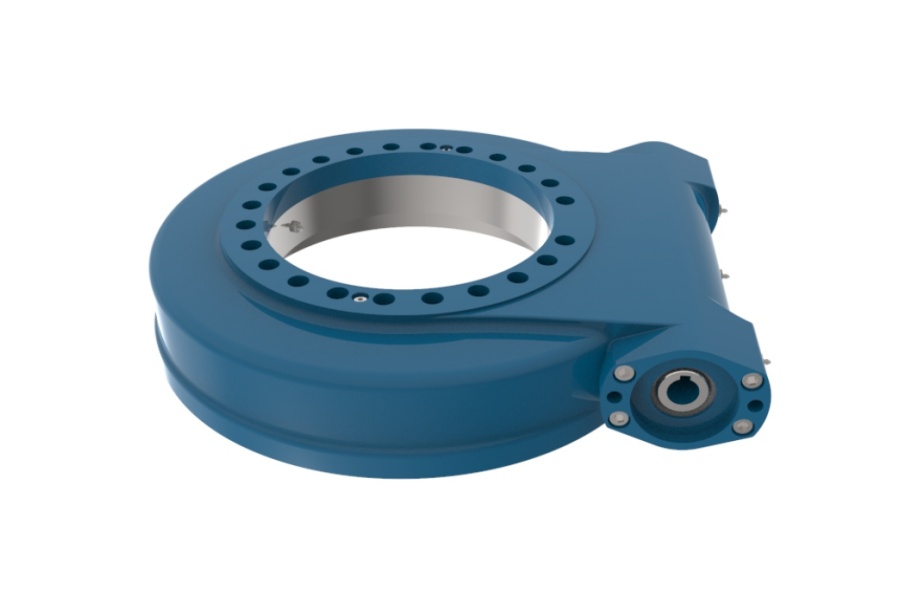

What is Worm Gear Slew Drive

Worm Gear Slew Drive combines a worm screw and wheel assembly with a slewing bearing to achieve ultra-high reduction ratios. These systems provide inherent self-locking properties essential for vertical load holding. With reduction ratios reaching 300:1 in compact packages, they excel in safety-critical applications requiring position security without external brakes.

Industrial Application Comparison

Material Handling Systems

Spur gear variants power high-speed warehouse automation including palletizing systems and AS/RS rotators handling 30+ cycles/hour. Their efficiency sustains continuous operation in automated distribution centers. Conversely, worm gear drives dominate truck-mounted cranes and light hoisting equipment where vertical load security prevents dangerous backward driving during lifting operations.

Mobile Machinery Solutions

Agricultural equipment relies on spur gear drives for grain unloading arms rotating at 15-25 RPM and forestry vehicle cab rotation systems. These applications benefit from minimal energy loss during extended operation. Worm gear units excel in road maintenance sweepers, mini-excavators, and municipal vehicles like concrete mixers where self-locking ensures operational safety on inclines.

Renewable Energy Installations

Multi-megawatt wind turbines utilize spur gear drives for precise yaw control systems requiring 98% efficiency. Their high-speed capability maintains optimal blade alignment during wind shifts. Worm gear alternatives serve residential solar trackers under 5kW capacity and micro wind turbines where compact self-locking mechanisms prevent wind damage during storms.

Construction Equipment Implementation

Drilling rig turntables handling 500,000Nm moments employ spur gear technology for reliable bidirectional rotation. Heavy-duty concrete pumps depend on their consistent performance under shock loads. Compact excavator attachments favor worm gear solutions for attachment rotators where space constraints demand high reduction ratios in minimal footprints.

Technical Performance Profile

Spur Gear Slew Drives operate at 65-75 dB(A) noise levels with 10,000-hour maintenance intervals. They achieve output speeds to 50 RPM but require external brakes for load holding. Moderate shock load tolerance makes them suitable for dynamic industrial environments.

Worm Gear Slew Drives generate 70-85 dB(A) operational noise with 5,000-hour relubrication cycles. Their typical 3-10 RPM output range provides controlled motion. Excellent shock absorption suits heavy-impact applications like demolition equipment.

Critical Pricing Determinants

Spur gear drive costs increase exponentially beyond 100kNm torque capacity. ISO 6 precision gearing adds 35% over standard ISO 8 equivalents. Cross roller bearings increase cost 25% versus four-point contact designs. IP69K environmental sealing contributes 18-22% to base pricing. Custom flanges or mounting interfaces incur 15% engineering premiums. Material upgrades to 18CrNiMo7-6 alloy elevate costs 30% over standard steel. Marine certifications (DNV-GL) add 12-18% compliance expenses.

Supplier

LYRADRIVE delivers engineered rotational systems through ISO-certified manufacturing of both spur and worm gear configurations. Our application specialists select drive types based on dynamic load analysis, operational duty cycles, and total lifecycle cost optimization. With 50+ standard models and full customization capabilities, we serve offshore crane operations, precision solar tracking, and heavy industrial automation sectors. Technical support includes gear type selection, lubrication optimization, and maintenance planning.