Selecting Precision Grades for Slew Drive Applications

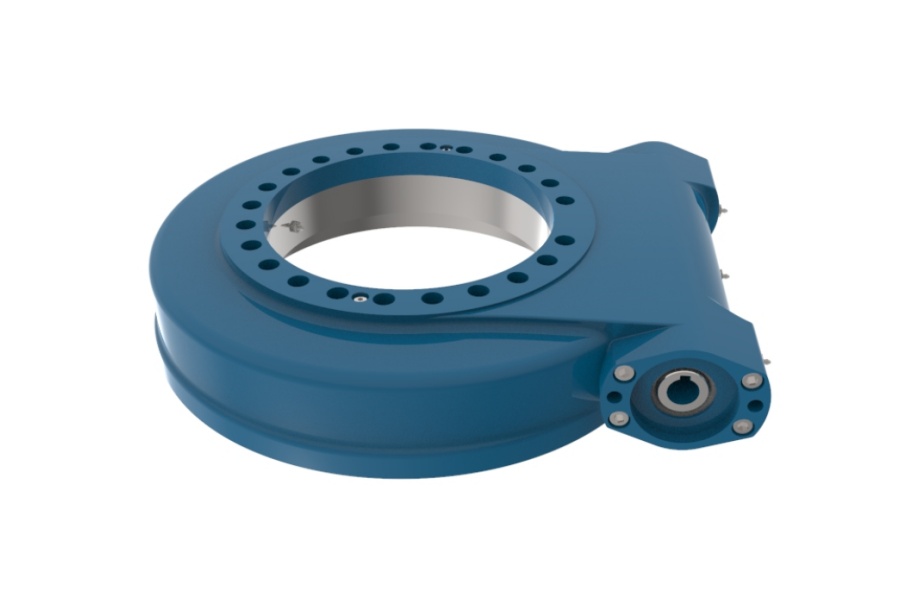

What is Slew Drive

Slew Drive integrates a precision gear reducer with a slewing bearing within a single housing, converting high-speed motor input into controlled rotational movement while simultaneously supporting axial, radial, and moment loads across industrial applications.

Precision Selection Methodology

Gear accuracy fundamentally determines backlash control and operational efficiency. LYRADRIVE engineers employ this four-parameter framework:

Power Transmission Analysis

Calculate maximum torque transmission requirements

Determine tooth bending strength (σ_F) and surface durability (σ_H)

Establish minimum module size under peak loads

Spatial Optimization

Evaluate installation envelope constraints

Optimize gear diameter-to-module ratio

Balance compactness with thermal management needs

Acoustic Performance Targets

Define permissible noise levels (dB(A))

Analyze gear mesh excitation frequencies

Higher precision reduces vibration harmonics

Motion Control Specifications

Quantify positioning repeatability (arc-minutes)

Establish backlash tolerance thresholds

Determine speed reversal frequency requirements

Precision Classification System

Grade | Backlash | Noise | Efficiency | Applications |

5 | ≤0.25° | <62 dB | 99%+ | Optical systems, Medical imaging |

6 | 0.25-0.5° | <68 dB | 98% | Radar positioning, Robotics |

7 | 0.5-1° | <75 dB | 95-97% | Crane rotation, Wind turbine pitch |

8 | 1-2° | <82 dB | 90-94% | Material handling, Agricultural systems |

Validation Protocol

Cross-reference requirements with 200+ historical designs

Conduct finite element analysis of tooth contact patterns

Test prototypes under accelerated duty cycles (300% overload)

Measure positional accuracy with laser interferometry

Critical Slew Drive Characteristics

Integrated Load Capacity: Combined moment resistance to 750,000 Nm

Environmental Protection: IP68/IP69K sealing for harsh conditions

Extended Service Life: 100,000+ hour design lifespan

Temperature Resilience: -40°C to +150°C operational range

Corrosion Resistance: Marine-grade coatings available

Industry-Specific Applications

Medical Grade (5-6): CT scanner gantries, surgical robots

Industrial Grade (7): Automated welding positioners, crane jibs

Commercial Grade (8): Solar trackers, packaging machinery

Heavy-Duty (7-8): Excavator attachments, drilling rigs

Precision Cost Drivers

Gear Manufacturing: Grade 5 grinding costs 4× Grade 8 hobbing

Bearing Tolerance: ABEC 7 adds 35-50% over standard

Calibration Process: Laser alignment requires 20+ technician hours

Material Selection: Vacuum-remelted steels increase cost 40%

Testing Validation: CMM inspection adds 18-25% to production

Certifications: ISO 9001/13485 compliance increases 15-20%

Supplier of Slew Drive

LYRADRIVE delivers application-optimized slew drives through ISO 1328-compliant manufacturing, leveraging proprietary selection algorithms that cross-reference operational parameters with 50+ standard configurations; our technical team combines finite element simulation with field validation data to balance precision requirements against cost efficiency for medical, aerospace, and heavy industrial applications.