Selecting Couplings for Spur Gear Slew Drive Design

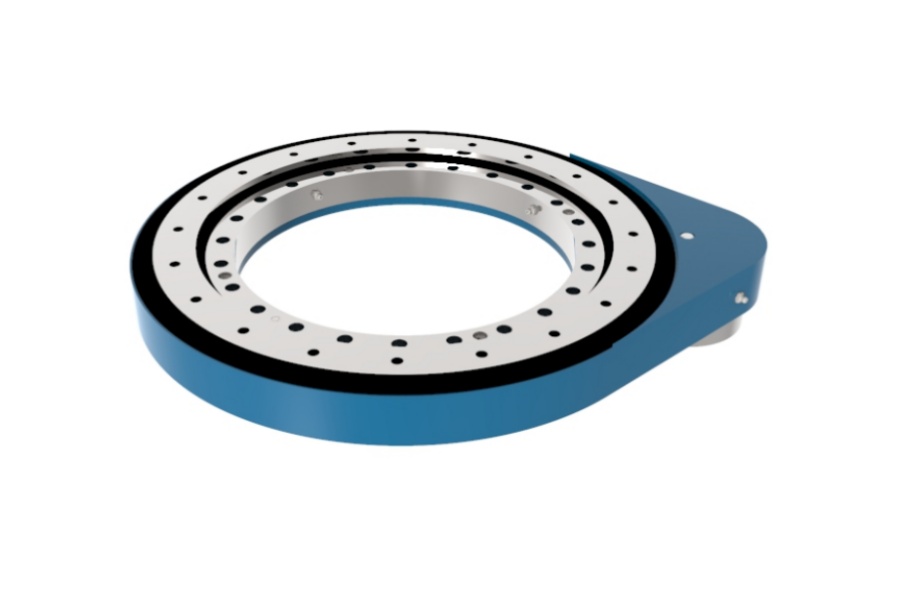

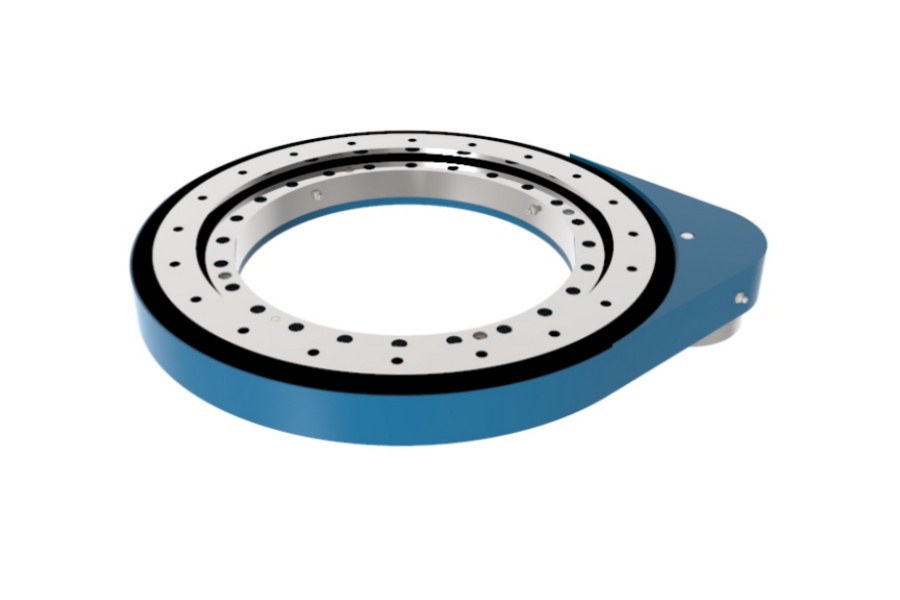

What is Spur Gear Slew Drive

Spur Gear Slew Drive is an integrated rotational actuator that combines a spur gear reducer directly with a slewing bearing. It converts the high-speed, low-torque input from a motor into slow, high-torque rotational output at the slewing ring. Unlike worm gear variants, spur gear drives utilize straight-cut teeth meshing parallel to the axis of rotation. This configuration offers high efficiency, compact design, and the ability to handle significant radial and axial loads simultaneously. Precise motor connection via a properly selected coupling is critical to its performance and durability.

How to Select Couplings for Spur Gear Slew Drives

Couplings are mechanical devices connecting two shafts (e.g., motor shaft and drive input shaft) to transmit torque and motion permanently. While rigid couplings exist, flexible couplings are overwhelmingly preferred for Spur Gear Slew Drives due to their ability to accommodate misalignment, absorb shock loads, dampen vibrations, and compensate for thermal expansion. Their advantages include significant elastic deformation capacity, lighter weight, high internal damping, and typically requiring no lubrication. Selecting the right coupling involves evaluating multiple critical factors:

Assess Shaft Misalignment: Accurately determine the type and magnitude of expected misalignment between the motor shaft and the slew drive input shaft:

Parallel Offset: Distance between the centerlines of the two shafts.

Angular Misalignment: Angle formed between the two shaft centerlines.

Axial Displacement: Movement of the shafts towards or away from each other along their axis.

Torsional Flexibility: The coupling's ability to twist slightly under load to dampen torque spikes.

Different coupling types excel at accommodating specific combinations of these misalignments. Jaw couplings handle moderate angular and parallel offset well. Beam couplings offer good angular and axial flexibility but limited parallel offset. Bellows couplings provide high torsional stiffness while accommodating angular and parallel misalignment. Disc couplings handle high torque and misalignment with excellent torsional rigidity. Grid couplings are robust and dampen shock loads effectively.

Calculate Torque and Speed Requirements: Precisely define the operational demands:

Rated Torque: The continuous torque the coupling must transmit during normal operation.

Peak Torque: The maximum transient torque (e.g., during start-up, stall, or sudden load changes) the coupling must withstand without failure.

Maximum Operating Speed (RPM): The highest rotational speed the coupling will experience.

The coupling's rated torque must exceed the application's peak torque (often applying a service factor based on the driven equipment type). Ensure the coupling's maximum rated speed exceeds the application's top speed.

Evaluate Environmental Conditions: The operating environment significantly impacts coupling selection:

Temperature: Extreme high or low temperatures affect material properties and lubricants (if applicable). Choose materials (e.g., stainless steel, specific polymers) and designs suitable for the temperature range.

Contaminants: Exposure to dust, dirt, moisture, chemicals, or abrasive particles necessitates couplings with effective sealing (e.g., shrouded designs, sealed disc packs) or inherently corrosion-resistant materials.

Lubrication Requirements: While many flexible couplings are maintenance-free (elastomeric, metallic disc, bellows), some types (e.g., gear couplings) require periodic lubrication, which may be undesirable in sealed or clean environments.

Consider Space and Weight Constraints: The physical envelope available for the coupling is crucial:

Bore Sizes: The coupling must accommodate the diameters of both the motor shaft and the slew drive input shaft.

Overall Length: The coupling's length impacts the spacing between the motor and the drive. Compact designs are often preferred.

Outside Diameter: Ensure sufficient radial clearance around the coupling.

Weight: Minimizing weight is critical in mobile or high-dynamic applications.

Match Shaft Dimensions (Initial Sizing): Based on the shaft diameters and required shaft engagement lengths (keyway length if applicable):

Identify couplings rated for the required torque/speed that can physically fit the larger of the two shaft diameters. Shaft diameters often differ between motor and drive.

The coupling's bore size must match the shaft diameter, and the required keyway dimensions (if using a keyed connection) must be compatible.

Verify the coupling's maximum bore capacity and minimum/maximum engagement length meet or exceed the application's requirements.

Verify Performance and Conduct Strength Checks: After selecting a candidate coupling model based on the above:

Confirm its rated torque (with appropriate service factor applied) exceeds the application's peak torque.

Ensure its maximum speed rating exceeds the application's maximum operating speed.

Verify its misalignment capacity (angular, parallel, axial) meets or exceeds the calculated/expected values.

Perform Shaft and Key Strength Analysis: Calculate the stresses on both the motor shaft and the slew drive input shaft at the coupling connection point under peak torque conditions. Ensure the shafts and any keyways have sufficient strength and fatigue life to handle these stresses. This step is critical to prevent shaft failure or key shearing.

Key Features of Spur Gear Slew Drives

Spur Gear Slew Drives offer distinct advantages derived from their core design:

High Efficiency: Spur gear meshing typically achieves 95-98% efficiency per stage, significantly higher than worm gear drives, reducing energy consumption and heat generation.

Compact Design: Integration of the gearbox and bearing into a single unit saves space and simplifies mounting.

High Load Capacity: Capable of handling substantial combined radial, axial, and moment loads directly at the point of rotation via the integrated slewing bearing.

Bi-Directional Operation & High Speed Capability: Spur gears transmit torque equally well in both directions and can operate at higher input speeds compared to many worm drives.

Precision Positioning: Achieves high accuracy and repeatability, especially with preloaded bearings and high-quality gear manufacturing.

Lower Cost Potential: Generally more cost-effective than equivalent capacity worm gear slew drives, particularly at higher power levels, due to simpler gearing.

Primary Applications of Spur Gear Slew Drives

The efficiency and performance characteristics of spur gear slew drives make them ideal for numerous demanding applications:

Wind Energy: Dominant choice for wind turbine yaw systems (nacelle positioning) and pitch control (blade angle adjustment) due to high efficiency and reliability.

Material Handling: Powers heavy-duty crane slewing, rotating heavy industrial positioners, automated storage/retrieval systems (AS/RS), and large turntables.

Construction Equipment: Used in excavator attachments, drilling rig rotation, concrete boom placers, and heavy machinery requiring robust rotation.

Industrial Automation: Drives indexing tables, robotic welding positioners, large valve actuators, and automated assembly lines requiring precise, high-speed positioning.

Marine & Offshore: Powers deck cranes, winches, davits, and A-frames on ships and offshore platforms.

Test Equipment: Used in dynamometers and other heavy-duty test stands requiring precise torque application and positioning.

Factors Influencing Spur Gear Slew Drive Pricing

The cost of a Spur Gear Slew Drive is determined by several key factors:

Size & Load Rating: Larger drives designed for higher axial/radial loads, overturning moments, and output torque require significantly more material, larger bearings, and heavier machining, increasing cost.

Gear Quality & Precision: High-precision gear grinding (vs. hobbing), achieving low backlash specifications, and superior surface finishes increase manufacturing costs substantially.

Bearing Type & Quality: The integrated slewing bearing is a major cost driver. Factors include type (ball, roller, cross roller), size, precision grade, load capacity, sealing effectiveness (IP rating), and brand reputation.

Material Selection: Using high-strength alloy steels (e.g., 42CrMo, 18CrNiMo7-6) for gears and shafts, along with advanced heat treatment processes (case hardening, carburizing, nitriding), significantly enhances durability and performance but also cost.

Sealing & Environmental Protection: Achieving high Ingress Protection (IP65, IP66, IP67) ratings for operation in harsh environments (dust, water, salt spray, chemicals) requires complex multi-lip seal designs, specialized lubricants, and meticulous housing machining, adding cost.

Customization: Non-standard mounting interfaces (flanges, bolt patterns), special shaft configurations (splines, different ends), unique coatings, or specific paint requirements incur additional engineering and manufacturing expenses.

Internal Components: The choice of bearings within the gear reduction stage (e.g., tapered rollers vs. ball bearings), the complexity of the planet carrier (for planetary stages), and the design of the pinion shaft assembly impact cost.

Lubrication System: Integrated automatic lubrication systems add complexity and cost.

Production Volume & Brand: Higher production volumes generally reduce unit cost. Drives from established manufacturers with strong reputations for quality and reliability often command premium prices. Certifications (ISO 9001, DNV-GL, etc.) also contribute to cost.

Reliable Spur Gear Slew Drive Supplier

LYRADRIVE is a leading manufacturer of robust and efficient Spur Gear Slew Drives, engineered for demanding applications worldwide. We specialize in providing solutions that optimize power transmission, featuring integrated designs compatible with high-performance flexible couplings for reliable motor connection. LYRADRIVE drives are built using high-strength materials, precision gear manufacturing, and quality bearings, ensuring longevity under heavy loads. Our expertise supports diverse industries including wind energy, heavy lifting, construction, and industrial automation. We offer technical guidance on coupling selection and integration, along with customization options to meet specific requirements.