Exploring Primary Worm Types in Slew Drive Gear Design

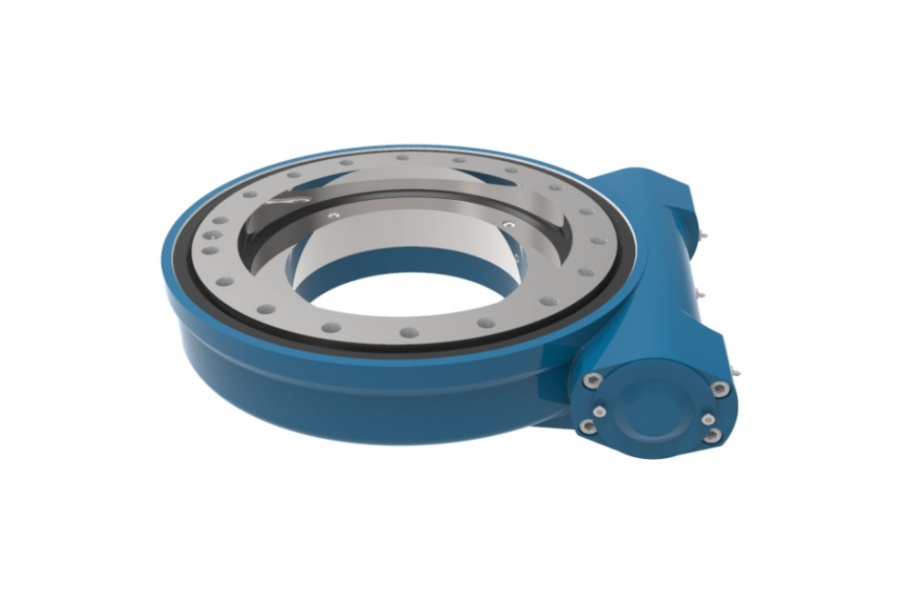

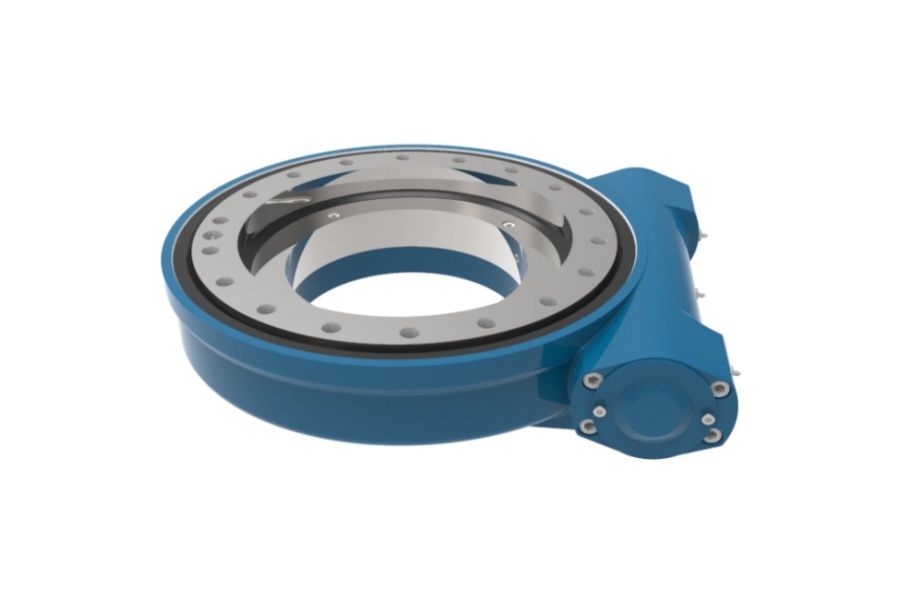

What is Worm Gear Slew Drive

Worm Gear Slew Drive is an integrated mechanical assembly combining a high-ratio worm gear reducer with a slewing bearing. It efficiently converts high-speed, low-torque input from a motor (typically connected to the worm shaft) into slow, high-torque rotational output at the slewing ring. This compact unit provides precise positioning, high load capacity, and inherent self-locking capability, making it essential for controlled rotational motion in demanding applications like solar trackers, cranes, and heavy-duty machinery. The worm gear interface, specifically the design of the worm shaft itself, is fundamental to its performance.

Common Worm Types in Slew Drive Design

The choice of worm profile significantly impacts the performance, efficiency, manufacturability, and cost of a Worm Gear Slew Drive. Here are the four primary types encountered:

ZA (Archimedes) Cylindrical Worm: The ZA worm features a straight-sided axial profile resembling a trapezoidal thread. It is the simplest and most economical to manufacture, typically produced using a straight-edged cutting tool aligned with the worm axis in a lathe. This simplicity makes it widely used. However, its primary contact is theoretically point contact, leading to higher localized stresses. It generally has fewer teeth in contact simultaneously. Consequently, ZA worms are best suited for applications with lower loads, slower speeds, and fewer starts/stops, often where cost is a major factor. Their transmission efficiency typically ranges from 0.35 to 0.8. Think of it as the reliable workhorse for less demanding duties.

ZN (Normal Straight Sided) Cylindrical Worm & ZI (Involute) Cylindrical Worm: The ZN worm has straight sides in the normal plane (perpendicular to the tooth), while the ZI worm features an involute helicoid profile in the transverse plane. Both types offer significant advantages over the ZA worm. Their improved tooth geometry promotes better contact patterns (approaching line contact under load) and reduced friction, resulting in higher efficiency (up to 0.9). They also accommodate multiple starts (threads) more effectively, allowing for higher reduction ratios or faster output speeds. These worms require more precise manufacturing (often involving specialized hobbing or grinding) but deliver superior performance in applications needing higher speed, greater precision, and better efficiency than ZA worms can provide, even with fewer simultaneous contact points.

ZK (Convolute - Cone Generated) Cylindrical Worm: The ZK worm is generated using a conical milling cutter or grinding wheel, resulting in a profile defined by the cutter's shape and motion. This manufacturing method offers excellent flexibility and precision. ZK worms can be efficiently produced via hobbing or grinding, making them suitable for both initial production and high-precision, hardened versions. They achieve high efficiency (up to 0.9) comparable to ZN/ZI worms due to favorable meshing conditions and the ability to achieve smooth, precise tooth flanks. Their manufacturability and performance balance make them a popular choice for a wide range of demanding slew drive applications requiring good efficiency and precision, again typically engaging fewer teeth simultaneously.

ZC (Circular Arc) Cylindrical Worm: The ZC worm features a concave circular arc profile in the normal section. This unique geometry enables true line contact with a properly matched concave wheel, significantly increasing the contact area (typically engaging 2-3 teeth simultaneously). This larger contact area dramatically reduces contact stress, making ZC drives exceptionally suited for high-load and heavy-shock applications. While manufacturing requires specialized grinding wheels or form cutters, the resulting drive offers excellent load distribution and durability. Efficiency ranges widely (0.65 to 0.95) depending on the specific design, manufacturing precision, and lubrication; well-made ZC drives can achieve very high efficiency. This type is the preferred solution for the most demanding, heavy-duty industrial environments like mining, large construction equipment, and heavy material handling where maximizing load capacity and longevity is critical.

Key Features of Worm Gear Slew Drives

Worm Gear Slew Drives derive core characteristics from their integrated worm gear mechanism:

High Torque Output & Reduction Ratios: Delivers substantial torque multiplication from a compact package, often achieving single-stage ratios from 5:1 to over 300:1.

Inherent Self-Locking: The friction angle within the worm mesh typically prevents back-driving by the output load, ensuring position holding without brakes (static loads). Dynamic braking may still be needed.

Compact & Integrated Design: Combines reducer and bearing into one unit, saving space and simplifying installation.

Robust Load Capacity: The integrated slewing bearing handles significant combined radial, axial, and moment loads directly at the rotation point.

Precision Positioning: Capable of high accuracy and repeatability, especially with low-backlash designs and precise worm/wheel manufacturing.

Smooth Operation: Properly designed and lubricated worm gears provide relatively quiet and vibration-free motion.

Primary Applications of Worm Gear Slew Drives

The unique advantages of these drives make them indispensable across diverse sectors:

Renewable Energy: Dominates solar tracking (single-axis and dual-axis) for optimal panel alignment; used in wind turbine yaw and pitch control.

Material Handling & Lifting: Powers crane jib rotation, aerial work platform positioning, knuckle boom movement, and industrial turntables/positioners.

Construction Machinery: Found in excavator attachments, drilling rigs, concrete pumpers, and compact cranes for precise movement under load.

Industrial Automation: Drives welding positioners, indexing tables, robotic arm joints, large valve actuators, and radar/satellite dish positioning.

Specialized Equipment: Used in medical imaging devices, defense systems (turrets), stage machinery, and packaging lines requiring controlled rotation.

Factors Influencing Worm Gear Slew Drive Pricing

Cost is determined by multiple interrelated factors:

Worm Type & Manufacturing Complexity: ZA worms are generally cheapest. ZN/ZI, ZK, and especially ZC worms require more complex machining (hobbing, grinding) and specialized tooling, increasing cost. ZC drives often command a premium.

Size & Load Rating: Larger drives handling higher axial/radial loads, overturning moments, and torque require more material, larger bearings, and heavier machining.

Precision & Performance Requirements: Ultra-low backlash, high positional accuracy, or maximum efficiency demands tighter tolerances, superior bearing grades, gear grinding, and rigorous QC.

Materials & Heat Treatment: High-strength alloy steels (e.g., 42CrMo, 20MnCr5) and advanced hardening processes (carburizing, nitriding) significantly increase durability and cost versus standard steels.

Bearing Type & Quality: The slewing bearing's size, type (ball, cross roller), precision grade, seals, and brand are major cost components.

Sealing & Protection (IP Rating): High IP ratings (IP65, IP66, IP67) for harsh environments need complex seals and housing designs.

Lubrication System: Integrated automatic lubrication or special grease requirements add cost.

Customization: Non-standard mounting, shafts, coatings, or interfaces incur engineering and setup costs.

Volume & Brand: Higher volumes reduce unit cost. Established brands with quality certifications (ISO 9001) often command premium prices.

Market Factors: Raw material costs (steel), tariffs, and regional manufacturing expenses fluctuate.

Reliable Worm Gear Slew Drive Supplier

LYRADRIVE is a leading designer and manufacturer of high-performance Worm Gear Slew Drives, offering solutions engineered for reliability and efficiency across global industries. Our expertise encompasses the full spectrum of worm technologies, from robust ZA designs for cost-effective solutions to advanced ZC configurations for maximum heavy-duty performance. LYRADRIVE leverages precision manufacturing and rigorous quality control to ensure drives meet exacting specifications for load capacity, efficiency, and longevity. We serve diverse sectors including solar energy, material handling, construction, and industrial automation, providing technical support and customization options.